Leave Your Message

In the rapidly evolving landscape of industrial solutions, technical ceramics have emerged as a vital component driving innovation and performance across various sectors. The title "2025 Top Technical Ceramic Innovations Transforming Industry Solutions - '2025 Top 10'" highlights a significant milestone in the continuous integration of advanced ceramics into modern applications. As businesses seek enhanced durability, heat resistance, and lightweight materials, the advancements in technical ceramics promise to deliver unprecedented solutions that meet these demands.

This overview aims to explore the most groundbreaking technical ceramic innovations anticipated to redefine industries by 2025. From aerospace and automotive applications to electronics and biomedical fields, these ceramics are pushing the boundaries of what is possible, offering unique properties that traditional materials cannot. As we delve into this exciting landscape of innovation, we will uncover the specific technologies and applications that are poised to revolutionize industry solutions.

By examining the "2025 Top 10" technical ceramic innovations, we not only highlight individual achievements but also showcase the collective potential of these materials to enhance efficiency, performance, and sustainability across diverse sectors. This exploration underscores the importance of technical ceramics in shaping the future of industry and fulfilling the increasingly complex needs of modern engineering challenges.

Advancements in high-strength technical ceramics are poised to revolutionize aerospace applications, offering enhanced performance characteristics that meet the demanding requirements of the industry. The integration of ceramic matrix composites (CMCs) as strategic thermal structure materials has gained momentum, attributed to their lightweight and high-temperature resistance. This innovation aligns with the rapidly growing market, which is projected to witness significant expansion, emphasizing the increasing reliance on advanced composite materials in aerospace engineering.

Advancements in high-strength technical ceramics are poised to revolutionize aerospace applications, offering enhanced performance characteristics that meet the demanding requirements of the industry. The integration of ceramic matrix composites (CMCs) as strategic thermal structure materials has gained momentum, attributed to their lightweight and high-temperature resistance. This innovation aligns with the rapidly growing market, which is projected to witness significant expansion, emphasizing the increasing reliance on advanced composite materials in aerospace engineering.

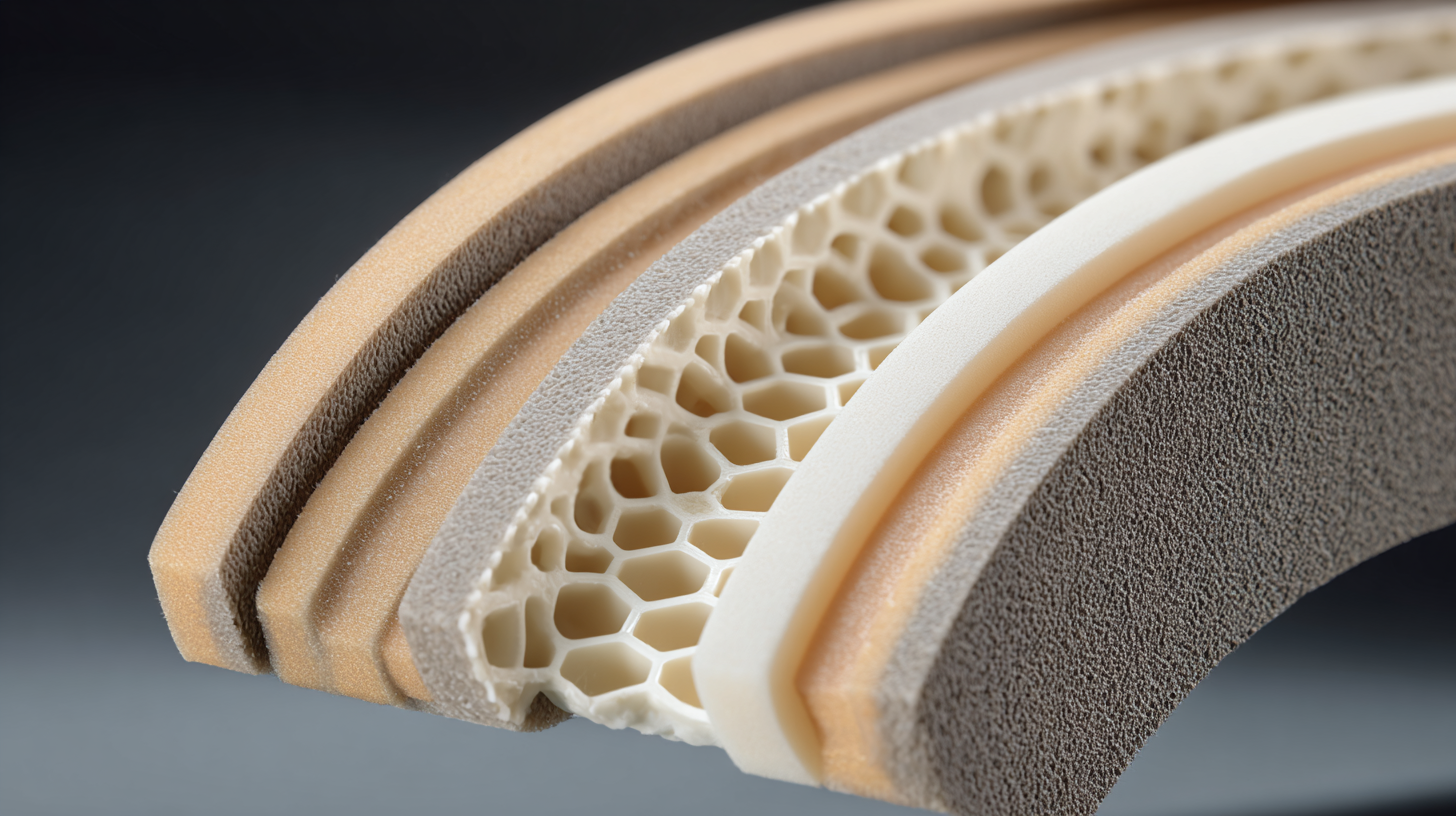

Recent breakthroughs in manufacturing techniques, such as 3D printing of high-performance ceramics, have opened the door to creating complex structures that were previously unattainable. These techniques allow for near-net shaping, which minimizes material waste and enables rapid prototyping. As the aerospace sector continues to seek solutions that enhance fuel efficiency and reduce overall weight, the innovative capabilities of CMCs and advanced ceramic materials present a compelling path forward, demonstrating their vital role in shaping the future of aerospace technologies.

Innovative wear-resistant ceramics are paving the way for significant transformations in manufacturing efficiency across various industries. These advanced materials exhibit exceptional durability and can withstand extreme conditions, making them ideal for use in high-wear applications. For example, in the aerospace and automotive sectors, the implementation of wear-resistant ceramics can dramatically reduce component failures and extend the lifespan of critical parts, ultimately leading to significant cost savings and enhanced performance.

Moreover, the incorporation of these innovative ceramics into production processes enables manufacturers to achieve higher precision and quality in their final products. By minimizing wear and tear on machinery, companies can maintain tighter tolerances and reduce downtime associated with maintenance and replacements. The development of these materials also supports sustainability efforts, as the longer lifespan of ceramic components contributes to less waste over time. With ongoing advancements in ceramic technologies, industries are poised to reap the benefits of greater efficiency and improved profitability.

The emergence of bioactive ceramics is poised to revolutionize healthcare solutions, addressing a pressing need for advanced materials in medical applications. According to a recent report by Market Research Future, the global bioactive ceramics market is expected to exceed $1.5 billion by 2025, driven by the increasing use of these materials in orthopedic and dental implants. These ceramics, such as hydroxyapatite and bioactive glass, have the unique ability to interact with biological tissues, promoting healing and integration with bone. Their biocompatibility and bioactivity have opened new avenues in regenerative medicine, enabling more effective treatments for a variety of conditions.

Tips: When considering bioactive ceramics for healthcare applications, it’s essential to assess the specific requirements of the treatment. Factors such as mechanical strength, degradation rate, and bioactivity should be analyzed to ensure optimal patient outcomes. Collaborating with healthcare professionals can provide insights into how these materials can be tailored for particular clinical needs.

Moreover, the advancements in 3D printing technology are further enhancing the capabilities of bioactive ceramics, allowing for customized implants that match the unique geometries of patients. According to a study published in the Journal of Materials Science, 3D-printed bioactive ceramic scaffolds have shown promising results in supporting bone regeneration in preclinical models, demonstrating their potential in clinical settings. As research continues, the application of these materials in personalized medicine will likely expand, driving innovations in surgical techniques and post-operative care.

The future of technical ceramics is increasingly aligned with sustainable manufacturing processes, paving the way for innovations that not only enhance performance but also minimize environmental impact. This shift towards eco-friendly methods involves the implementation of advanced recycling technologies and the use of renewable materials in the production of ceramics. By adopting these sustainable practices, manufacturers can significantly reduce waste and energy consumption, ensuring that next-generation technical ceramics meet both industrial demands and environmental standards.

Moreover, innovations such as additive manufacturing are revolutionizing the way technical ceramics are produced. This method allows for more precise control over the materials used, enabling the incorporation of non-toxic and biodegradable components. As a result, the new ceramics exhibit improved mechanical properties while maintaining ecological integrity. The integration of smart technologies, such as real-time monitoring and AI-driven optimization, further enhances the sustainability of the manufacturing process, allowing for adaptive production that responds directly to demand and resource availability. Through these advancements, the ceramics industry is setting a benchmark for responsible manufacturing while driving technological progress forward.

The integration of Internet of Things (IoT) technology into technical ceramics is revolutionizing various industries by enhancing performance and efficiency.  Smart technical ceramics equipped with IoT sensors enable real-time monitoring and data collection, allowing for immediate analysis and response to changing conditions. This innovation paves the way for more responsive manufacturing processes, predictive maintenance, and improved quality control, ultimately leading to reduced downtime and operational costs.

Smart technical ceramics equipped with IoT sensors enable real-time monitoring and data collection, allowing for immediate analysis and response to changing conditions. This innovation paves the way for more responsive manufacturing processes, predictive maintenance, and improved quality control, ultimately leading to reduced downtime and operational costs.

Moreover, the application of IoT in technical ceramics is driving advancements in product development and resource management. For instance, ceramics used in aerospace and automotive sectors can now communicate key performance indicators, such as temperature and stress levels, directly to maintenance teams. This capability not only facilitates timely interventions but also contributes to safer and more sustainable operations.

As industries continue to embrace these smart materials, the potential for increased automation and smarter decision-making expands, setting new standards for performance in various applications.