Leave Your Message

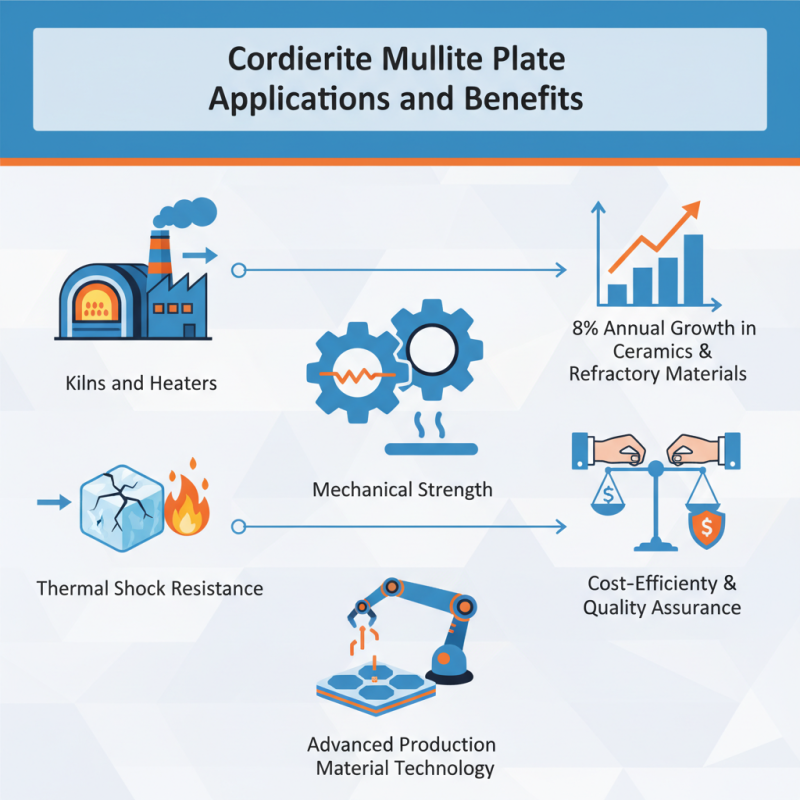

The Cordierite Mullite Plate has gained significant attention in various industrial applications. Recent market reports indicate a growth rate of 8% annually in the ceramics and refractory materials sector. This growth highlights the increasing demand for high-performance materials.

Cordierite Mullite Plates are well-regarded for their thermal stability and mechanical strength. Industries utilize them for kilns and heaters where high temperatures are common. Their ability to withstand thermal shock makes them ideal for manufacturing processes. However, challenges remain in optimizing their production for specific applications.

Discrepancies in material quality can affect performance outcomes. Manufacturers must strike a balance between cost-efficiency and quality assurance. Understanding these dynamics is crucial for businesses looking to invest in Cordierite Mullite Plates. The future of these plates hinges on advancements in production techniques and material technology.

Cordierite mullite plates have gained attention for their versatility in industrial applications. These plates are known for their exceptional thermal stability and low thermal expansion. They resist shock and can handle extreme temperature variations. This makes them ideal for kilns and furnace linings, where durability is crucial. Industries benefit from these plates due to reduced maintenance costs and longer service life.

Another significant advantage is their excellent insulation properties. Cordierite mullite plates help maintain energy efficiency by minimizing heat loss. This is vital for companies aiming to reduce energy consumption. However, the production process can be inconsistent, leading to variations in quality. It’s essential for manufacturers to ensure a reliable supply chain to maintain performance standards. Improving this aspect can enhance the overall benefits of using these plates in applications.

Additionally, the lightweight nature of cordierite mullite plates facilitates their handling and installation. This can lead to quicker project timelines. Yet, care must be taken during transport to prevent damage. Overlooking this can result in unnecessary delays. Emphasizing proper handling methods will ensure that these valuable plates perform to their full potential.

Cordierite mullite is recognized for its exceptional thermal stability. This property is vital in high-temperature applications. The material can withstand extreme heat without significantly expanding or warping. This attribute makes it ideal for use in kilns and furnaces. High performance is often linked to its impressive thermal shock resistance. It swiftly absorbs and dissipates temperature changes, reducing the risk of cracking.

Another key aspect is its lightweight nature, which can lead to energy savings during transportation and installation. Despite its advantages, some users may overlook its cost-effectiveness. Initial investment might seem high. However, the longevity of cordierite mullite can outweigh this concern. Users may also worry about the material's potential brittleness under certain conditions.

Chemical resistance is another benefit worth mentioning. Cordierite mullite can withstand various aggressive environments. This feature enhances its usability in diverse industries. Users often seek materials that can handle challenges without frequent replacements. Still, some applications might reveal limitations that need exploration. Understanding both the strengths and weaknesses is crucial for making informed choices.

Cordierite mullite is gaining attention for its unique properties. Its excellent thermal stability makes it ideal for high-temperature applications. Compared to other ceramic materials, it offers better thermal shock resistance. This feature is crucial in industries where rapid temperature changes occur. Cordierite mullite plates can withstand these conditions effectively.

In contrast, common ceramics often fail under extreme stress. Their brittleness can lead to cracking. Cordierite mullite’s toughness helps mitigate this risk. However, it may lag behind in certain mechanical strengths. This could be a deal-breaker for some applications. Potential users should weigh these factors carefully.

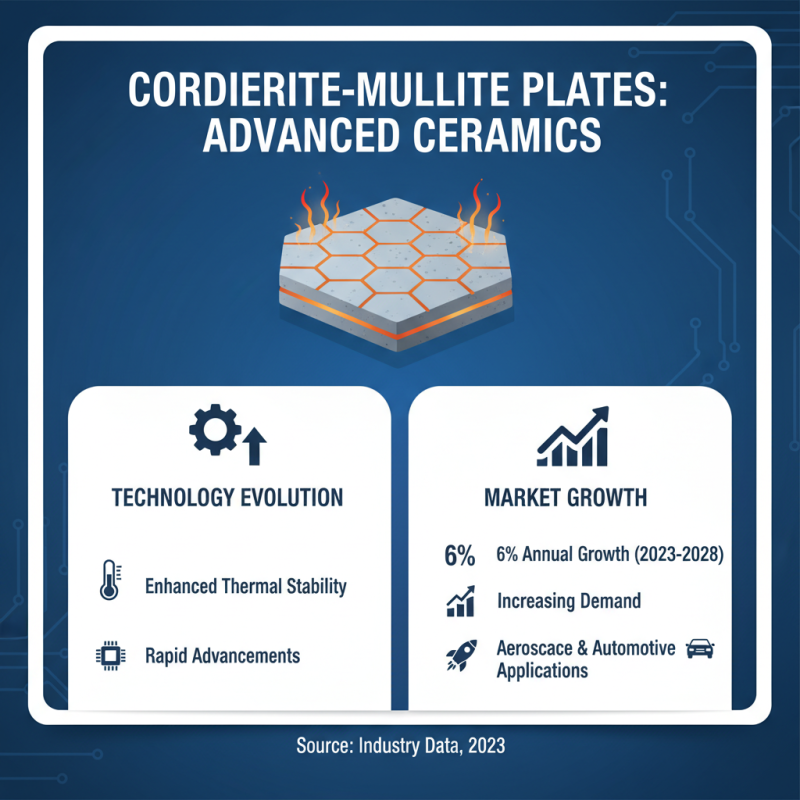

Versatility is another point to consider. Cordierite mullite serves in various sectors, from aerospace to automotive. Its lightweight nature is advantageous in reducing overall weight. But challenges remain, such as manufacturing costs. This trade-off must be understood fully. Users might feel pressured to balance price and performance.

| Characteristic | Cordierite Mullite | Other Ceramic Materials |

|---|---|---|

| Thermal Stability | Excellent | Good |

| Mechanical Strength | High | Moderate |

| Thermal Conductivity | Low | Variable |

| Cost | Moderate | Varies |

| Applications | Refractory components, Kiln furniture | Insulators, Structural parts |

| Weight | Lightweight | Heavy |

In various industries, cordierite mullite plates are making waves. These plates offer remarkable thermal stability and excellent resistance to thermal shock. This makes them ideal for applications in foundries and kilns. Industries are starting to realize the value of using these materials for better efficiency.

Many manufacturers are leveraging cordierite mullite plates for production processes. In ceramics, for instance, they provide even heat distribution. This consistency improves product quality. However, the initial cost may deter some businesses. They must weigh costs against long-term efficiency gains.

Another area benefiting is aerospace. High-temperature applications require materials that can withstand extreme conditions. Cordierite mullite plates fulfill that role effectively. Yet, not every organization understands their potential. Education on these materials is crucial for broader adoption. Efforts should focus on demonstrating real-world benefits.

The technology behind cordierite mullite plates is evolving rapidly. Manufacturers are now focusing on enhancing thermal stability. Recent data indicates that the market demand for advanced ceramics is expected to grow at a rate of 6% annually through 2028. This growth is driven by increasing applications in industries like aerospace and automotive.

Innovative techniques, such as advanced sintering methods, are being explored. These methods aim to improve the mechanical properties of cordierite mullite plates. A study shows that plates with optimized compositions can withstand temperatures exceeding 1400°C. However, these innovations can come with challenges. The complexity of production processes can lead to inconsistencies in quality.

Another interesting trend is the integration of nano-additives. These additives enhance toughness and thermal resistance. While promising, there’s limited data on their long-term performance. The industry must reflect on balancing innovation with reliability. As technology evolves, it is crucial to keep an eye on sustainability practices in material sourcing. With the right approach, cordierite mullite plates can lead to significant advancements.