Leave Your Message

High temperature applications are demanding. Industries seek materials that withstand extreme conditions. Among these, the Corundum Mullite Plate stands out for its unique properties. According to a report by the International Materials Research Institute, the market for high-temperature ceramics is expected to reach $8 billion by 2027. This growth signifies the rising importance of durable materials like Corundum Mullite Plate.

Dr. James Anderson, a leading expert in ceramic materials, emphasizes, “The Corundum Mullite Plate is essential for modern high-performance applications.” Its benefits include excellent thermal stability and low thermal expansion. These characteristics allow it to perform effectively under harsh thermal cycling. However, while the material offers numerous advantages, challenges remain. Consistent quality control can be difficult. Additionally, the initial cost can be a barrier for some manufacturers.

Understanding the full potential of Corundum Mullite Plate involves exploring both its strengths and limitations. The industry must address these shortcomings to maximize its effectiveness. Further research into improving the manufacturing process could enhance its viability. As demand in various sectors grows, so does the need for innovations surrounding this crucial material.

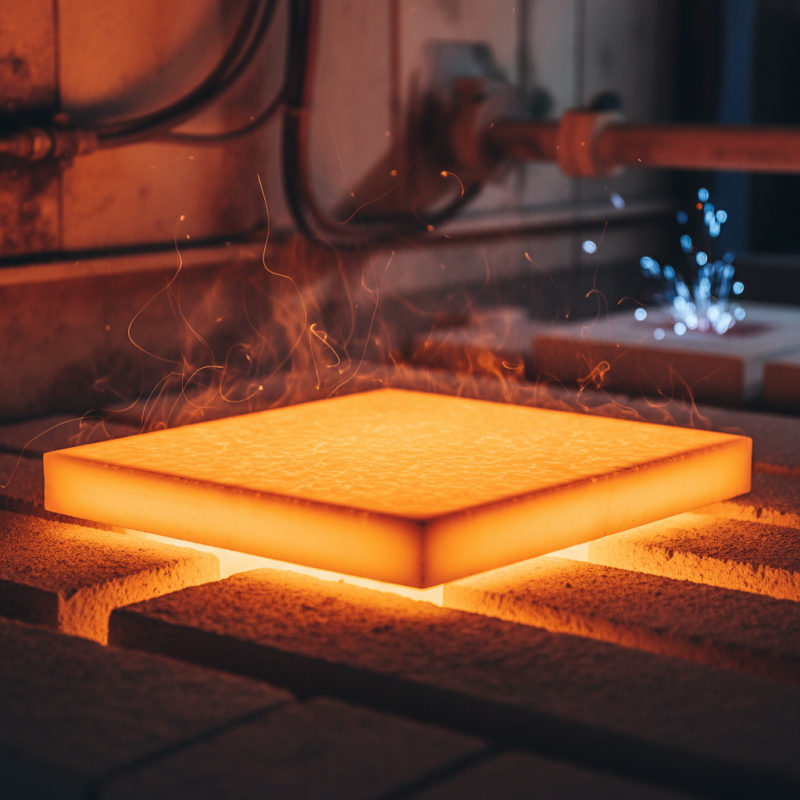

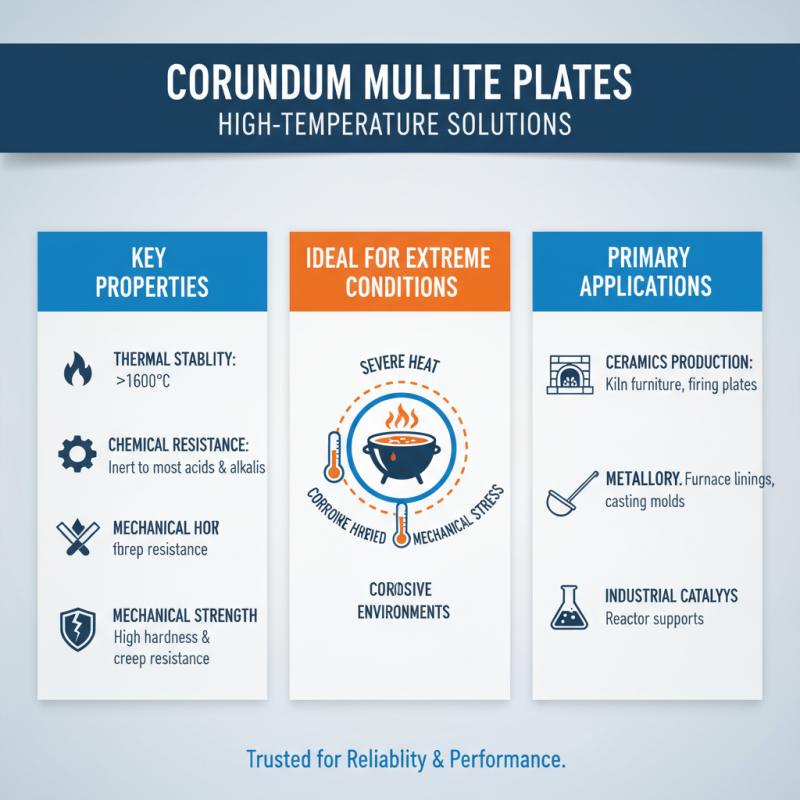

Corundum mullite plates are essential in high-temperature applications. Their composition typically consists of aluminum oxide and silica, resulting in remarkable thermal stability. This unique blend allows these plates to withstand temperatures exceeding 1600°C. According to industry reports, the thermal shock resistance of corundum mullite is significantly higher than that of traditional refractories.

In various sectors, these plates maintain structural integrity and resist deformation under extreme conditions. Data indicates that corrosion resistance is another key benefit. Unlike many ceramics, corundum mullite shows minimal degradation when exposed to aggressive environments. However, the production process requires careful monitoring. Minor variations in raw material ratios can lead to significant performance discrepancies.

Practitioners must also consider the cost-effectiveness. While upfront expenses may be higher, the long-term durability of corundum mullite plates can reduce maintenance costs. Nonetheless, thorough evaluation is necessary for specific applications. Overlooking this could lead to premature failures, impacting operational efficiency. Therefore, a balanced approach in selection remains vital to harness the true potential of these advanced materials.

Corundum mullite plates are increasingly favored for high-temperature applications. Their key properties make them ideal for extreme conditions. One significant feature is their excellent thermal stability. They can withstand temperatures exceeding 1600°C without degradation, which is crucial in industries like ceramics and metallurgy.

Another vital aspect is their low thermal expansion. This property helps maintain structural integrity under rapid temperature changes. It reduces the risk of cracking and ensures long-lasting performance in demanding environments. Corundum mullite plates also exhibit remarkable resistance to chemical corrosion. They can endure harsh chemicals, making them suitable for various industrial processes.

In looking at some potential drawbacks, the manufacturing process can be complex and costly. This could hinder wider adoption in certain sectors. Furthermore, while they offer several benefits, it's important to consider that not all applications may require such high-performance materials. Balancing cost and performance is critical when choosing the right materials for specific needs.

Corundum mullite plates offer exceptional thermal shock resistance. This quality is crucial for high-temperature applications. These plates can endure rapid temperature changes without cracking. This durability is vital in industries like metallurgy and ceramics.

Thermal shock resistance minimizes failure rates. It prevents costly disruptions in manufacturing processes. These plates withstand extreme conditions, maintaining structural integrity. Forging, casting, and kiln operations can benefit significantly. However, not all formulations guarantee the same performance.

While corundum mullite is reliable, the composition varies. Different mixtures may lead to unexpected results. Ongoing testing helps to enhance understanding of these materials. It is essential to analyze their limits carefully. Keeping an eye on advancements ensures optimal use.

Corundum mullite plates have remarkable chemical stability, making them suitable for high-temperature environments. They resist oxidation and corrosion effectively. This resistance is crucial in industries that operate under extreme conditions. Chemical reactions can weaken materials, leading to failure. Corundum mullite reduces this risk, ensuring longer life and reliability.

In applications like kilns and reactors, chemical stability is vital. Exposure to various gases and substances can lead to degradation. Corundum mullite maintains its structure, supporting consistent performance. Its ability to withstand harsh chemicals is an advantage many industries seek. However, not all high-temperature materials share this trait. Some may corrode or break down quickly.

While the benefits are substantial, there is a need to examine potential weaknesses. Despite its durability, certain extreme chemicals could pose a threat. Not all environments are predictable. Regular assessments are necessary to ensure continued efficacy. Continuous monitoring can help in identifying any weaknesses early. This ensures that the benefits of corundum mullite plates are fully realized in high-temperature applications.

Corundum mullite plates are gaining popularity in various industrial applications. These plates withstand extreme temperatures, making them ideal for kilns and furnaces. Their unique properties support structural integrity under heat. For instance, in the ceramics industry, they aid in the creation of high-quality products that require intense firing processes. The durability of these plates enhances efficiency and safety.

In metallurgical applications, corundum mullite plates serve as linings for transfer ladles and furnaces. They resist thermal shock, which is critical during temperature fluctuations. Their light weight helps reduce energy consumption. However, careful consideration is necessary when integrating these materials. Some users report challenges in installation and alignment of the plates. Practical knowledge and skilled labor are essential to optimize performance.

In the glass industry, corundum mullite plates provide reliable support during melting processes. Their refractoriness prevents deformation, ensuring consistent product quality. Despite their advantages, ongoing maintenance is vital. Over time, wear and tear can lead to performance issues. Users must regularly inspect these plates to prevent costly downtime. Choosing the right application can further enhance their effectiveness in demanding environments.

| Benefit | Description | Applications |

|---|---|---|

| High Thermal Stability | Maintains structural integrity at high temperatures. | Refractories, furnaces |

| Low Thermal Conductivity | Reduces heat loss during processes. | Insulation products |

| Good Mechanical Strength | Provides durability in extreme conditions. | Industrial kilns, heat exchangers |

| Chemical Resistance | Resistant to various corrosive environments. | Chemical reactors, molten metal contact |

| Ease of Fabrication | Can be easily shaped and installed. | Custom applications, repair work |

| Low Shrinkage | Maintains dimensions under heat. | High precision settings |

| Thermal Cycling Resistance | Withstands repeated heating and cooling. | Glass manufacturing, aerospace |

| Lightweight | Facilitates easier handling and installation. | Transportation, construction |

| Refractory Properties | Can handle extreme heat effectively. | Industrial boilers, metal smelting |

| Cost-Effective | Offers long-term savings on maintenance. | Manufacturing sectors, continuous operations |