Leave Your Message

Alumina ceramic has emerged as a key material across various industries. Its unique properties offer advantages that drive innovation. This material is known for its strength, hardness, and thermal resistance. As we look toward 2026, the applications of alumina ceramic promise even greater benefits.

In the manufacturing sector, alumina ceramic is widely used. Components made from this material are found in machinery, dental products, and even electronics. Its durability is unmatched. However, the cost of production can be a concern. This may limit its use for some companies. Understanding these dynamics is essential for effective application.

New developments are on the horizon. Researchers are exploring ways to enhance the performance of alumina ceramic. This includes improvements in processing methods and formulations. However, challenges remain. Ensuring sustainability while maintaining performance is crucial. The potential of alumina ceramic is vast, yet it requires continual reflection on its impact.

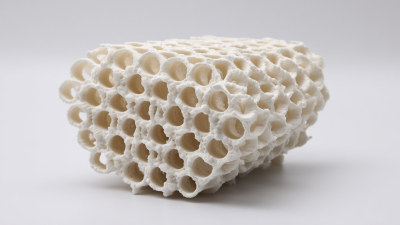

Alumina ceramics are known for their excellent mechanical properties. They boast high hardness and wear resistance. This makes them suitable for various demanding applications. Additionally, alumina ceramics have impressive thermal stability. They can withstand extreme temperatures, which is crucial in many industries.

The chemical resistance of alumina is another valuable trait. It does not corrode easily when exposed to acids and bases. This characteristic is vital in manufacturing equipment and medical devices. Furthermore, alumina ceramics are lightweight. Their thin structure can still provide strong support in various applications.

That said, there are challenges with alumina ceramics. They can be brittle, making them prone to cracking under sudden stress. This needs to be addressed during design and application. While the advantages are clear, potential limitations in tough environments warrant attention. Thus, careful evaluation is essential in selecting alumina ceramics for specific uses.

| Application | Benefits | Typical Properties |

|---|---|---|

| Electronic Insulators | High dielectric strength and thermal stability | Dielectric constant: 9-10, Insulation resistance: 10^14 Ω·cm |

| Cutting Tools | Excellent wear resistance and cutting performance | Hardness: 1500 HV, Density: 3.9 g/cm³ |

| Biomedical Applications | Biocompatibility and corrosion resistance | Flexural strength: > 300 MPa, Porosity: < 0.1% |

| Wear-resistant Coatings | Increased longevity and performance | Thermal conductivity: 30 W/m·K, Hardness: 2000 HV |

| Insulating & Structural Parts | High strength and low thermal expansion | Young's Modulus: 300 GPa, Thermal expansion coefficient: ~7 × 10⁻⁶/K |

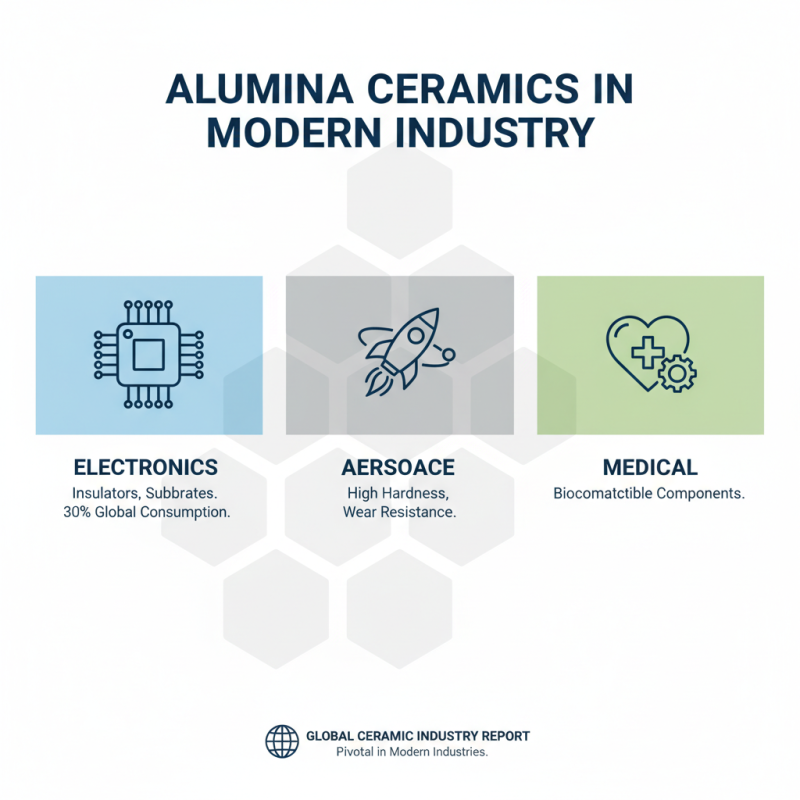

Alumina ceramics are pivotal in modern industries, especially in sectors like electronics, aerospace, and medical. Their high hardness and excellent wear resistance make them ideal for various applications. In the electronics field, alumina ceramics are widely used in insulators and substrates. A report from the Global Ceramic Industry highlights that the electronics sector accounts for approximately 30% of global alumina ceramic consumption.

Another significant application lies in the aerospace industry. Here, alumina ceramics serve critical functions in thermal protection systems. They prevent damage during high-speed flights. Industry data shows that the demand for aerospace-grade ceramics is expected to grow by 15% annually. This growth creates new opportunities and challenges for manufacturers.

Tips: When considering alumina ceramics for a project, assess specific application needs. Ensure the material's properties align with your requirements. Additionally, since not all alumina ceramics perform equally, conduct thorough research.

Meanwhile, the medical sector also benefits from alumina ceramics. They are used in prosthetics and dental implants due to their biocompatibility. However, achieving the perfect balance in properties remains a challenge. Manufacturers often face issues in production consistency. Thus, addressing these imperfections is crucial for future advancements.

Alumina ceramics are becoming popular in manufacturing for several reasons. They are known for their excellent mechanical strength. This makes them suitable for applications where durability is critical. They can withstand high temperatures, which is essential in many industrial processes. The hardness of alumina ceramics also contributes to their wear resistance, leading to longer-lasting tools and components.

When considering alumina ceramics, it's worth noting that they can be more brittle than some alternatives. This can lead to challenges during the manufacturing process. Care should be taken to avoid excessive stress. However, the benefits often outweigh these concerns, especially in high-performance applications.

Tips: Always test for compatibility with your specific processes. Proper design can mitigate some brittleness issues. For some users, it may be beneficial to combine alumina ceramics with other materials to enhance performance. This balance can lead to more effective solutions in various industries. Regular review and reflection on application needs can guide better material choices, making alumina ceramics a meaningful addition to many manufacturing settings.

In 2026, alumina ceramics will see innovative applications across various industries. One significant trend is the increased use of alumina for electrical insulation. Innovations have led to materials that withstand higher temperatures and provide superior dielectric properties. Reports indicate that the market for advanced ceramics is expected to reach approximately $50 billion by 2026, with alumina accounting for a substantial portion of this growth.

Another exciting development is in the medical field. Researchers are exploring the durability of alumina ceramics for dental implants and prosthetics. The material's biocompatibility and wear resistance make it an ideal candidate. A recent study highlighted a 20% increase in patient satisfaction with alumina-based solutions compared to traditional materials. Yet, challenges remain. The manufacturing processes for achieving high purity alumina can be inefficient, leading to higher costs.

In the automotive sector, alumina's application in brake pads is noteworthy. The material enhances performance and safety. Data from industry analysis shows a projected climb in the use of advanced ceramics in automotive applications, expected to exceed 30% by 2026. However, concerns about environmental impacts from production processes need addressing. This dual focus on innovation and sustainability will define the future of alumina ceramics in the coming years.

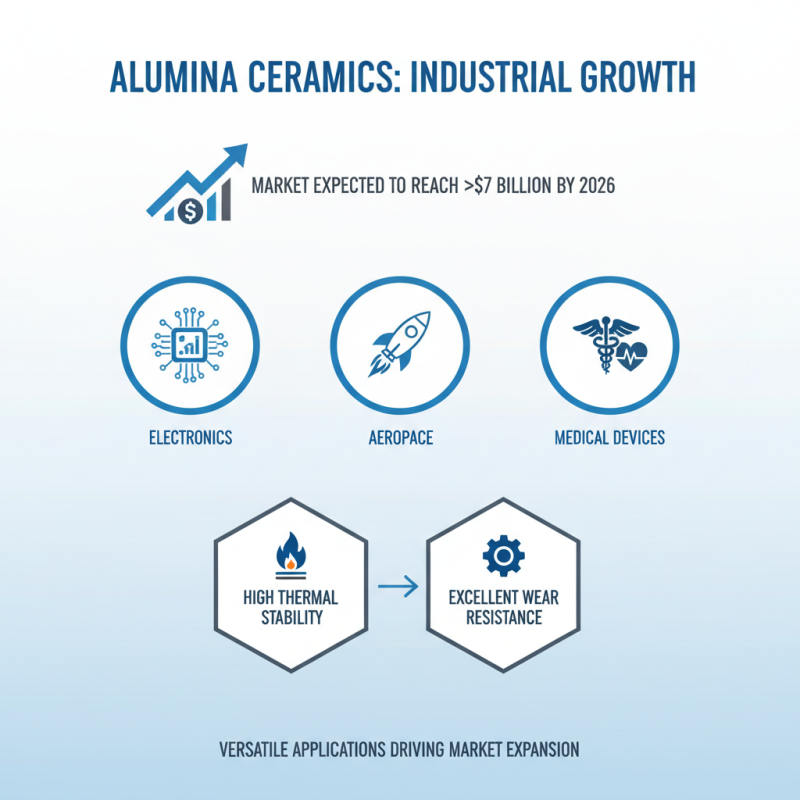

Alumina ceramics are gaining traction across various industries, driven by their unique properties. Their high thermal stability and excellent wear resistance make them suitable for diverse applications. According to a recent report, the global alumina ceramic market is expected to grow significantly, reaching over $7 billion by 2026. This growth reflects increasing demands in sectors like electronics, aerospace, and medical devices.

Future trends indicate a rise in innovative applications. For instance, in electronics, alumina ceramics are being tailored for advanced substrates in miniaturized devices. This shift towards smaller, more efficient components is reshaping design protocols. Challenges remain, such as ensuring reliability under extreme conditions. Engineers are consistently addressing these issues through research and development.

**Tip:** Stay updated on market reports and academic journals for the latest advancements in materials science. A proactive approach can enhance your knowledge and preparedness.

Moreover, AI technologies are beginning to influence the production processes of alumina ceramics. Integrating machine learning can improve material formulation and predict performance outcomes. However, the balance between innovation and existing methodologies often leads to debate. Finding the right direction is not always clear-cut.

**Tip:** Collaborate with industry experts to leverage insights. Engaging in discussions can provide different viewpoints and clarify complex issues.