Leave Your Message

In the world of ceramics and pottery, the selection of the right equipment is crucial for achieving quality results. As we look ahead to 2025, one of the most significant advancements in kiln accessories is the evolution of Silicon Carbide Kiln Shelves. These shelves are renowned for their exceptional strength and thermal stability, making them a preferred choice for artists and manufacturers alike. According to Dr. Emily Chen, a leading expert in material science, “Silicon Carbide Kiln Shelves not only enhance the longevity of your kiln but also improve the quality of the finished products, thanks to their ability to withstand extreme temperatures.”

Choosing the right Silicon Carbide Kiln Shelves involves understanding your specific needs and the unique characteristics of different shelf types. Factors such as size, thickness, and the intended application all play crucial roles in the decision-making process. As you navigate this landscape, it will be essential to consider the technical specifications and how they align with your firing schedules and ceramic materials. Equip yourself with the knowledge required to make informed choices, and you will maximize the efficiency of your kiln while unlocking the potential for exceptional artistry in your work.

Silicon carbide kiln shelves are essential components in high-temperature applications, offering a range of advantages that significantly enhance performance. These shelves are designed to withstand extreme heat, making them an ideal choice for a variety of industrial and artistic ceramic processes. The exceptional thermal stability of silicon carbide allows for consistent temperature distribution, which is crucial for achieving uniform results during firing. This ensures that delicate ceramic items are protected from warping and cracking, promoting higher quality outcomes.

Moreover, the durability of silicon carbide kiln shelves contributes to their long service life, making them a cost-effective investment. Unlike traditional materials, which may degrade over time when exposed to intense heat, silicon carbide retains its integrity, maintaining flatness and strength throughout multiple firings. This resilience not only reduces the need for frequent replacements but also enhances overall efficiency in kiln operations. Consequently, with silicon carbide kiln shelves, potters and manufacturers can focus on their crafting processes without the interruption and added costs associated with replacing worn or damaged shelves.

When choosing silicon carbide kiln shelves, understanding the different grades available is crucial for ensuring optimal performance and durability. Silicon carbide, known for its excellent thermal conductivity and mechanical strength, is available in various grades that can significantly influence the shelf's suitability for specific applications. Generally, these grades can be classified into three categories: standard, high purity, and advanced. Each grade is designed to meet specific temperature requirements and operational challenges, making it essential to select the right one based on your firing needs.

Standard grade silicon carbide shelves are typically used for general-purpose applications. They offer a good balance of performance and cost-effectiveness, making them ideal for potters and ceramic artists who need reliable shelves for everyday use. High purity silicon carbide shelves, on the other hand, are produced with minimal impurities, resulting in improved thermal properties and chemical resistance. These shelves are recommended for high-temperature applications and situations where contamination could affect the final product. Advanced grade shelves push the boundaries even further, providing the best resistance to thermal shock and mechanical stress, making them suitable for industrial applications where precision and reliability are paramount. Understanding these distinctions helps users select the right grade that aligns with their specific firing protocols and material requirements.

| Grade | Temperature Resistance (°C) | Load Capacity (kg) | Thermal Shock Resistance | Application |

|---|---|---|---|---|

| Standard | 1300 | 80 | Moderate | General ceramics |

| High-Temperature | 1500 | 100 | High | Stoneware, porcelain |

| Ultra-High Temperature | 1700 | 120 | Very High | Advanced ceramics, glass |

| Low Expansion | 1400 | 90 | High | Glassblowing, jewelry |

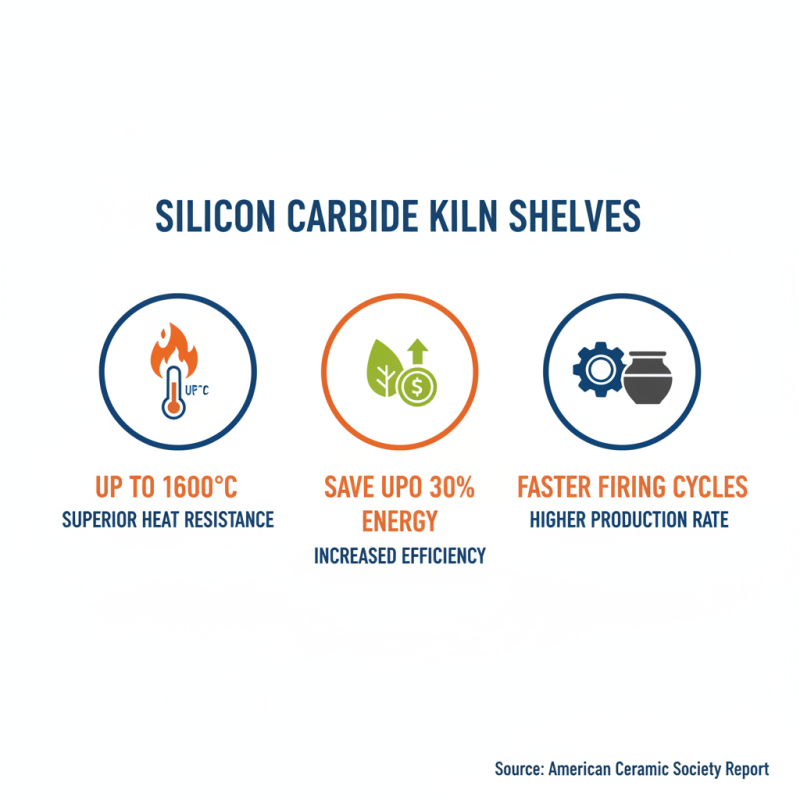

When selecting silicon carbide kiln shelves, there are several key factors that should be considered to ensure optimal performance and longevity. First, the thermal conductivity of the shelves is critical; silicon carbide is known for its excellent heat resistance and ability to withstand temperatures of up to 1,600°C. According to a report by the American Ceramic Society, kiln shelves made from high-quality silicon carbide can significantly reduce energy costs associated with firing, offering efficiency improvements of up to 30% compared to conventional materials. This allows potters and manufacturers to achieve higher production rates without sacrificing quality.

Another important consideration is the shelf thickness. Thicker shelves provide greater mechanical strength, which is essential for supporting heavier loads without warping or cracking. Industry studies indicate that shelves with a thickness of 1.25 inches offer a good balance between weight and support, especially for high-stakes firing processes. Additionally, the surface texture of the shelves plays a role in preventing glazes from sticking, facilitating easier removal of pieces post-firing. A well-textured surface ensures minimal interaction with glazes, which is vital for maintaining the integrity of both the shelves and the finished products. Making informed choices based on these key factors will help pottery professionals select the most suitable silicon carbide kiln shelves for their specific requirements.

When selecting kiln shelves, the choice between silicon carbide and traditional materials can significantly impact performance and efficiency. Silicon carbide shelves are known for their exceptional thermal conductivity and durability. They can withstand high temperatures without warping or cracking, making them ideal for both high-fire and electric kilns. In contrast, traditional kiln shelves, often made from cordierite or other ceramic materials, may not offer the same level of thermal shock resistance. As a result, they can be more susceptible to damage under extreme firing conditions.

Another important aspect to consider is the longevity and maintenance of the kiln shelves. Silicon carbide shelves tend to have a longer lifespan due to their robust construction, which translates into fewer replacements over time. Additionally, they require less maintenance compared to traditional options, as they are less prone to absorbing moisture and contaminants, which can affect the quality of the finished product. Therefore, while traditional kiln shelves may initially appear more economical, the long-term benefits of silicon carbide shelves often outweigh their higher upfront cost, especially for frequent firers looking for consistent results.

When selecting silicon carbide kiln shelves, understanding industry standards and certifications is crucial for ensuring quality and performance. These standards are often set by recognized organizations that focus on materials used in ceramics and high-temperature applications. For instance, look for certifications that guarantee the shelf can withstand high thermal shock, resist warping, and support heavy loads without compromising integrity. Compliance with these standards reflects that a product has undergone rigorous testing and meets specific technical requirements, making it a reliable choice for your kiln operations.

Additionally, consider the importance of fire resistance and durability in the context of kiln shelves. Industry certifications may indicate the maximum temperature ratings and the longevity of the materials when subjected to continuous use. Awareness of these specifications helps differentiate between shelves that may look similar but vary significantly in performance. Always prioritize products that adhere to established guidelines, as this not only contributes to the efficiency of your kiln but also enhances safety and minimizes the risk of costly failures during firing processes.