Leave Your Message

With the growing demand for high-performance materials in both dental and industrial applications, Zirconia Ceramic has emerged as a frontrunner due to its exceptional properties. According to a recent market analysis report by Grand View Research, the global Zirconia Ceramic market was valued at approximately $1.4 billion in 2021 and is projected to expand at a CAGR of 7.4% from 2022 to 2030. This growth is driven by its superior mechanical strength, biocompatibility, and aesthetic appeal, making it a preferred choice for dental restorations and various industrial components.

In the dental field, Zirconia Ceramic has revolutionized restorative practices, particularly in producing crowns and bridges. A study published in the Journal of Dental Research highlighted that over 70% of dentists prefer Zirconia for its durability and natural appearance. Meanwhile, in industrial sectors, its resistance to high temperatures and wear makes it indispensable in applications such as cutting tools and valves. As the demand for materials that can withstand extreme conditions continues to rise, understanding how to choose the best Zirconia Ceramic suited for specific needs becomes crucial for professionals in these industries.

Zirconia ceramics are becoming increasingly popular in both dental and industrial applications due to their excellent mechanical properties and biocompatibility. Understanding the composition of zirconia is essential for making informed choices. Primarily, zirconia (ZrO2) is a metal oxide derived from the mineral zircon. It can be stabilized with various oxides, such as yttria (Y2O3) or magnesia (MgO), to improve its toughness and thermal stability. The result is a material that possesses high strength and resistance to wear, which is crucial in both dental implants and industrial machinery.

When it comes to types of zirconia ceramics, two main categories emerge: fully stabilized zirconia and partially stabilized zirconia. Fully stabilized zirconia exhibits high resistance to transformation and is often used in dental applications, such as crowns and bridges, where aesthetics and durability are paramount. In contrast, partially stabilized zirconia is often employed in industrial settings, such as cutting tools and abrasive applications, due to its enhanced toughness. Each type serves distinct needs, highlighting the importance of understanding these variations when selecting the right zirconia ceramic for specific purposes.

Zirconia ceramics have garnered significant attention in both dental and industrial applications due to their exceptional properties. In dental settings, zirconia exhibits high flexural strength, often exceeding 900 MPa, making it an ideal choice for crowns, bridges, and implants. This strength ensures durability and longevity, crucial factors for patient satisfaction. Additionally, zirconia is known for its biocompatibility, meaning it integrates well with oral tissues and minimizes the risk of inflammation or adverse reactions, as supported by studies published in the Journal of Biomedical Materials Research.

Another key property of zirconia ceramics is their aesthetic versatility. They can be manufactured in a range of shades to closely mimic natural teeth, which is essential in cosmetic dentistry. This is achieved through precise color mixing techniques and the use of high-translucency zirconia, which allows light to pass through, creating a more lifelike appearance. Data from industry reports illustrate that aesthetic outcomes are a significant concern for over 70% of patients considering dental restorations.

**Tips:** When selecting zirconia ceramics, consider the manufacturing process used, as full contour and layered options provide different aesthetic results. Additionally, ensure proper shade matching by consulting with a dental technician. Always verify the certification and quality standards of the zirconia to guarantee optimal performance in both clinical and industrial applications.

Zirconia ceramics have rapidly gained prominence in both dental and industrial applications due to their exceptional durability and strength. In industrial settings, zirconia exhibits impressive mechanical properties, such as a fracture toughness of approximately 10 MPa·m^0.5, which makes it suitable for high-stress environments. According to a report by the Technical Ceramics Association, zirconia's resistance to wear and corrosion significantly exceeds that of traditional materials like stainless steel and aluminum, leading to longer service life and reduced maintenance costs in machinery and tooling.

Furthermore, the thermal stability of zirconia is noteworthy as it can withstand temperatures up to 2,000°C, making it an excellent choice for applications where thermal shock resistance is critical. The International Journal of Advanced Manufacturing Technology suggests that component failures in high-temperature environments can be mitigated by using zirconia ceramics, thus enhancing operational efficiency. This combination of mechanical strength and thermal resilience positions zirconia ceramics as a leading material for industries such as aerospace, automotive, and biomedical, where durability is paramount.

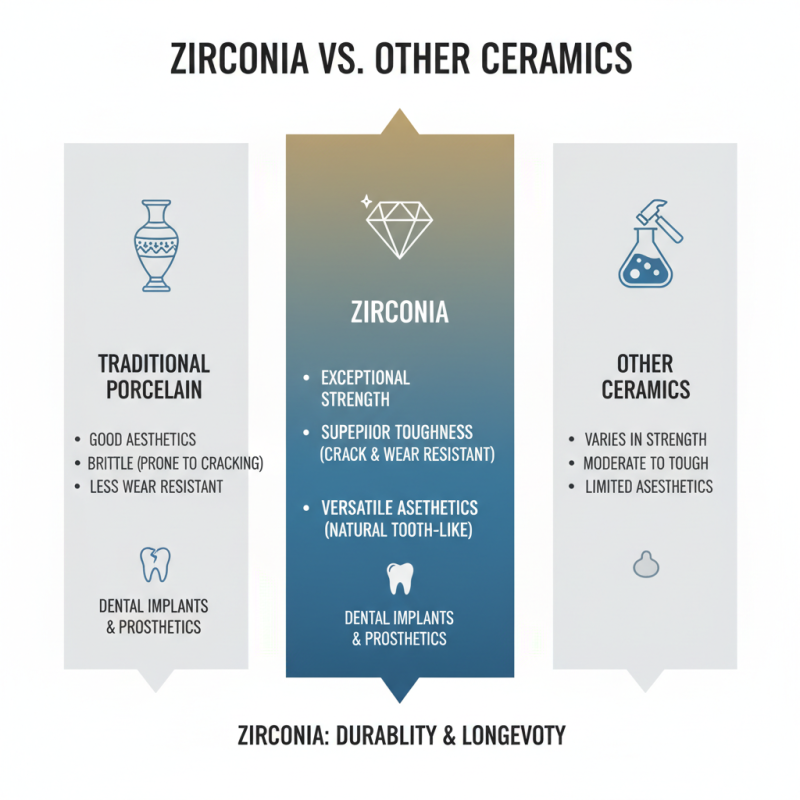

When evaluating zirconia ceramics against other ceramic materials, several key factors come into play, including strength, toughness, and aesthetic qualities. Zirconia is known for its exceptional mechanical properties, making it a preferred choice in demanding applications such as dental implants and prosthetics. Compared to traditional porcelain, zirconia offers superior resistance to cracking and wear, ensuring longevity and durability in both dental and industrial settings.

Moreover, when contrasting zirconia with other ceramics like alumina or lithium disilicate, zirconia stands out due to its superior toughness. While alumina is strong and has excellent wear resistance, it may not match zirconia's fracture toughness, which is critical in high-stress environments. On the other hand, lithium disilicate excels in aesthetics, often being favored for cosmetic restorations. However, its lower strength compared to zirconia limits its application in load-bearing dental restorations. Thus, the choice between these materials hinges on specific requirements, balancing mechanical properties with aesthetic considerations to meet the unique demands of different industries.

When selecting the right zirconia grade for specific applications, it’s crucial to consider the mechanical properties required for each use. In dental applications, for example, the strength, translucency, and biocompatibility of zirconia are paramount. Dental zirconia is often categorized by its yttria content, with 3Y-TZP (3 mol% yttria stabilized tetragonal zirconia polycrystal) being one of the most versatile options due to its excellent flexural strength and fracture toughness. This makes it suitable for fabricating crowns, bridges, and other restorations where aesthetic and functional properties are vital.

In industrial sectors, the choice of zirconia additionally hinges on thermal and wear resistance. For applications like cutting tools or wear parts, zirconia with higher zirconium oxide content, such as 8Y-TZP, may be preferred due to its enhanced hardness and durability under extreme conditions. Understanding the specific requirements of each application, such as environmental factors and the expected load, will guide the selection of the ideal zirconia grade, ultimately ensuring optimal performance and longevity.

| Zirconia Grade | Application | Properties | Recommended Use |

|---|---|---|---|

| 3Y-TZP | Dental Crowns | High strength, translucency | Optimal for esthetic restorations |

| 5Y-TZP | Dental Implants | Excellent toughness, biocompatibility | Ideal for load-bearing applications |

| ZrO2 | Industrial Applications | High wear resistance, thermal stability | Used in cutting tools and dies |

| Y-TZP | Dental Veneers | Good esthetics, strength | Preferred for front teeth restorations |

| TZP | Biomedical Applications | Corrosion resistance, high fatigue resistance | Suitable for orthopedic devices |