Leave Your Message

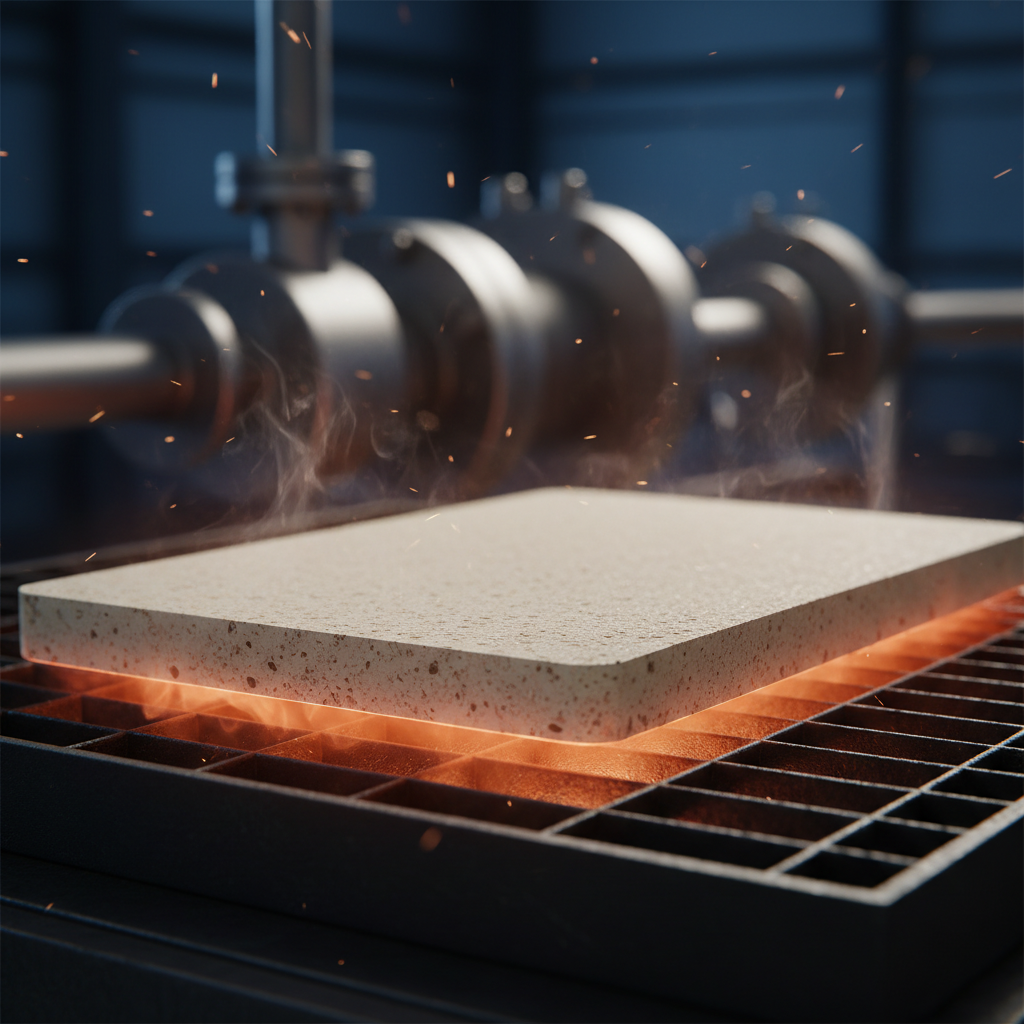

In the realm of high-temperature applications, selecting the appropriate material is paramount to ensuring efficiency, durability, and performance. Among the myriad of options available, the Cordierite Mullite Plate stands out as a superior choice due to its unique combination of properties that cater specifically to demanding thermal environments. This specialized ceramic material is engineered to withstand significant thermal stress, making it ideal for use in industries such as aerospace, metallurgy, and ceramics. As the need for materials that can endure intense temperatures and sudden thermal shocks increases, the Cordierite Mullite Plate offers a solution that not only meets but exceeds these rigorous demands.

The composition of Cordierite and Mullite grants these plates excellent thermal stability and low thermal expansion, which are critical for maintaining structural integrity in challenging conditions. Additionally, the lightweight nature of Cordierite Mullite Plates contributes to their versatility, allowing for easier handling and installation without compromising performance. Furthermore, their resistance to chemical corrosion ensures longevity, reducing the need for frequent replacements and maintenance. As we delve deeper into the advantages and applications of Cordierite Mullite Plates, it becomes evident that this material is not merely an option, but a vital asset for any high-temperature application, delivering reliability and efficiency that businesses can depend on.

Cordierite mullite plates have become an essential material in high-temperature applications due to their superior thermal stability and mechanical strength. In environments where temperatures exceed 1200°C, traditional materials often fail to perform adequately. According to a report by the American Ceramic Society, cordierite mullite demonstrates excellent thermal shock resistance, showing only minimal dimensional changes even under rapid temperature fluctuations. This property makes it ideal for kilns, furnaces, and other thermal processing equipment, where reliability and durability are paramount.

Furthermore, the low thermal expansion coefficient of cordierite mullite means that it can withstand considerable temperature gradients without cracking. A study from the International Journal of Applied Ceramic Technology emphasizes that cordierite mullite plates maintain their structural integrity in high-stress conditions, making them suitable for applications in aerospace and automotive engines where heat management is critical. The material’s high hardness and excellent wear resistance contribute to its longevity, reducing the frequency of replacements and maintenance, thus proving to be a cost-effective solution for high-temperature environments.

Cordierite mullite plates are increasingly recognized for their exceptional thermal properties and stability, making them ideal for high-temperature applications. These plates exhibit low thermal expansion and high thermal shock resistance, which allows them to withstand rapid temperature changes without cracking or deforming. This stability is especially crucial in industries where materials must endure extreme conditions, such as in kilns, furnaces, and other thermal processing equipment.

In comparison to other magnesium silicate ceramics like steatite, cordierite mullite offers a unique balance of density and melting points. While both types share a similar chemical structure, cordierite's specific attributes, such as lower thermal conductivity, enhance its performance in high-heat environments. This makes cordierite mullite plates not only efficient insulators but also reliable materials in various industrial applications, cementing their status in the global market for advanced ceramics.

Cordierite mullite plates are increasingly recognized for their exceptional mechanical strength and impressive resistance to thermal shock, making them an ideal choice for high-temperature applications. The unique combination of cordierite and mullite offers a strong structural integrity that can withstand significant mechanical stresses. This capability is crucial in environments where materials are subjected to heavy loads or potential impacts, ensuring longevity and reliability even under extreme conditions.

When it comes to thermal shock resistance, cordierite mullite plates shine due to their low thermal expansion coefficient. This characteristic allows them to endure rapid temperature fluctuations without cracking or deforming. In industries such as ceramics, glass manufacturing, and metallurgy, where temperature variations are commonplace, these plates provide an added layer of durability. Their ability to maintain stability and performance under severe thermal stress not only enhances operational efficiency but also reduces the risk of costly downtimes caused by material failure.

Cordierite mullite plates are increasingly recognized for their exceptional properties in high-temperature applications, particularly when compared to traditional ceramic materials. One of the standout features of cordierite mullite is its excellent thermal shock resistance, which is crucial in environments where rapid temperature fluctuations occur. According to a study by the American Ceramic Society, cordierite’s low thermal expansion coefficient (approximately 2.5 x 10⁻⁶/°C) makes it less prone to cracking under thermal stress compared to other ceramics like alumina, which has a significantly higher expansion rate.

Moreover, when assessing mechanical strength, cordierite mullite outperforms many common alternatives. In terms of flexural strength, cordierite can achieve values upwards of 150 MPa, while alumina’s strength plateaus around 200 MPa. However, the weight-to-strength ratio of cordierite mullite often puts it ahead in applications requiring lightweight materials, capitalizing on its unique composition. Furthermore, the lower density of cordierite (approximately 2.5 g/cm³) compared to other ceramics translates into enhanced thermal efficiency in high-performance environments, making it an attractive option for industries such as aerospace and automotive.

Cordierite mullite plates are increasingly utilized across various industries due to their remarkable thermal stability and mechanical strength. In the ceramics industry, for example, the high thermal shock resistance of cordierite mullite makes it an ideal choice for kiln furniture and other high-temperature applications. According to a report by Research and Markets, the global ceramic market is projected to reach $300 billion by 2025, with advanced ceramics like cordierite mullite expected to play a significant role in this growth due to their ability to withstand harsh thermal environments.

In the aerospace and automotive sectors, cordierite mullite plates are favored for manufacturing components such as high-performance insulators and heat shields. Their low thermal expansion and excellent insulation properties make them indispensable in ensuring the durability and efficiency of engines and other critical systems. The Aerospace Industries Association (AIA) indicates that the demand for high-performance materials in aerospace applications is projected to grow by 5% annually through 2026, highlighting the essential role of materials like cordierite mullite in high-temperature applications where performance reliability is paramount.

| Industry | Application | Temperature Resistance (°C) | Key Benefits |

|---|---|---|---|

| Ceramics | Kiln Furniture | 1300 | High strength, thermal shock resistance |

| Metallurgy | Refractory Linings | 1450 | Excellent thermal stability and insulating properties |

| Glass | Furnace Elements | 1250 | Low thermal expansion, high modulus of rupture |

| Chemical | Firing Applications | 1200 | Resistance to chemical corrosion and mechanical stress |

| Aerospace | Thermal Barriers | 1600 | Lightweight, exceptional heat insulation |