Leave Your Message

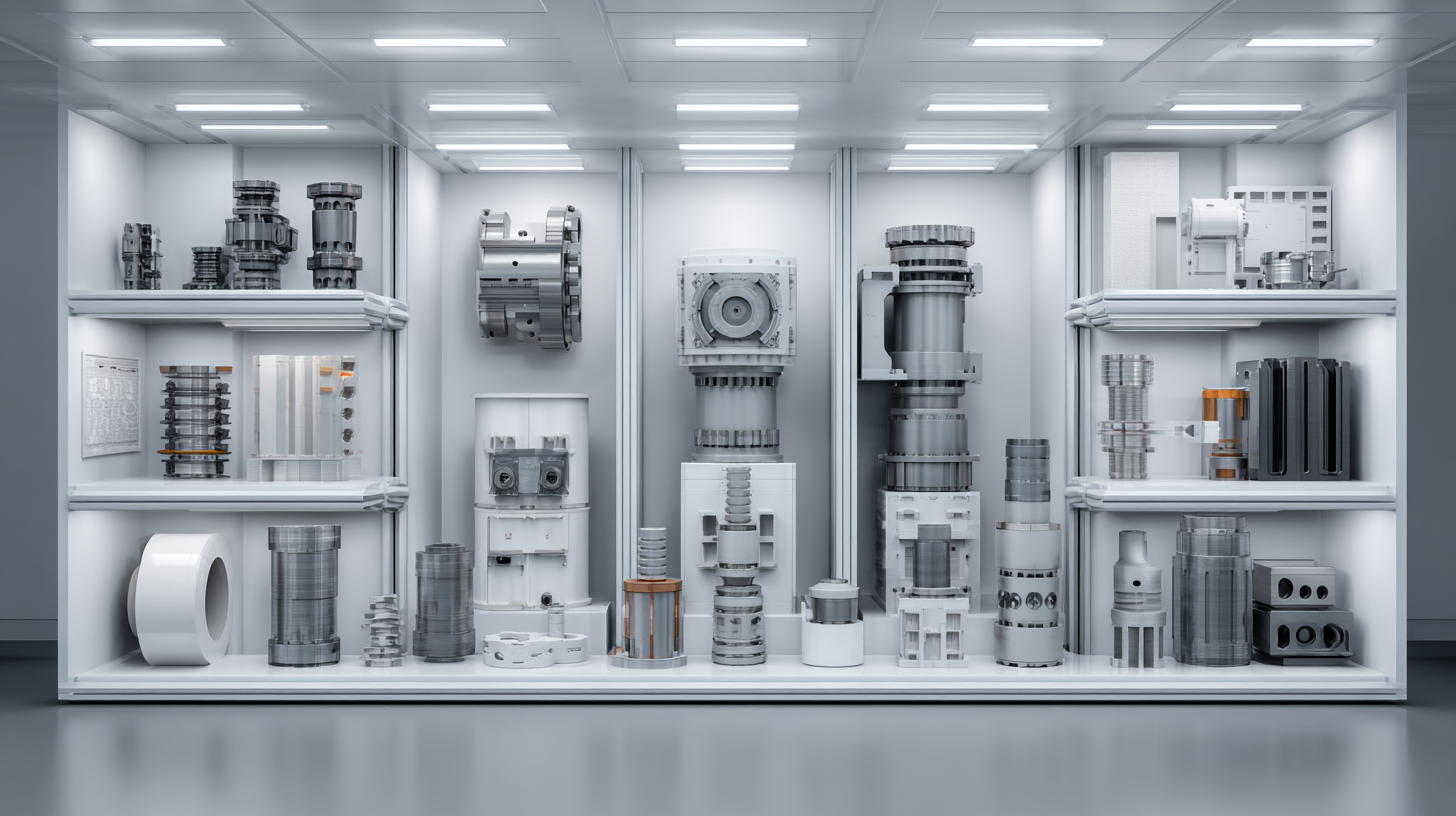

In today's fast-evolving industrial landscape, the selection of the right materials is pivotal for optimizing performance and ensuring longevity in applications. Technical ceramics, renowned for their exceptional mechanical, thermal, and chemical properties, have become increasingly vital across various sectors, including aerospace, electronics, and biomedical industries.

According to a report by MarketsandMarkets, the global technical ceramics market is projected to reach $112.9 billion by 2025, growing at a CAGR of 7.5% due to the rising demand for advanced materials. The unique attributes of technical ceramics, such as high thermal resistance, electrical insulation, and wear resistance, underscore the importance of making informed choices tailored to specific industry requirements. Understanding the diverse types and applications of technical ceramics is essential for engineers and procurement professionals aiming to enhance product reliability and performance.

When selecting the right technical ceramic for specific industry needs, it's essential to identify the unique requirements that each sector presents. Different applications may require varying properties such as high-temperature resistance, mechanical strength, or electrical insulating capabilities. For instance, the aerospace industry often demands ceramics that can withstand extreme thermal environments, while the medical field might prioritize biocompatibility and corrosion resistance in their material choices.

The production methods of technical ceramics also play a crucial role in their suitability for particular applications. Techniques like flame spray and High-Velocity Oxygen Fuel (HVOF) spraying are used to achieve certain microstructures and properties, which can enhance performance in demanding environments. Other methods, such as plasma spraying or cold spraying, might be deployed where unique surface characteristics or coatings are needed. Understanding the specific requirements and available production technologies allows industries to better match the right type of ceramic to their operational needs, ensuring optimal performance and longevity of components.

When selecting the right technical ceramic for specific industrial applications, it is crucial to evaluate mechanical properties such as hardness, strength, and wear resistance. For instance, silicon nitride ceramics have gained national recognition in the realm of dental implants, breaking through previous foreign technological monopolies. These ceramics exhibit exceptional hardness and strength, essential for enduring the demanding conditions of oral restoration.

Moreover, the advancement of silicon carbide fibers has solidified their position as ideal materials for aerospace applications. Their high-temperature oxidative resistance, impressive hardness, and strength make them favorable choices for components requiring durability and reliability in extreme environments. The increasing industrialization of advanced ceramics signifies not only their mechanical superiority but also their potential for widespread use across various high-tech fields.

This trend highlights the importance of understanding specific mechanical properties when choosing the right ceramic materials tailored to each industry's unique needs.

When selecting the appropriate technical ceramic for a specific industry application, understanding thermal conductivity and thermal expansion is critical. Ceramics, particularly advanced engineering grades, exhibit a wide spectrum of thermal conductivity values ranging from insulators to conductors. For instance, alumina, one of the most widely used technical ceramics, has a thermal conductivity of approximately 30 W/m·K, making it suitable for electronic applications requiring heat dissipation. In contrast, zirconia, another popular ceramic, boasts a lower thermal conductivity of around 2.5 W/m·K, which is beneficial in applications requiring thermal insulation, such as in high-temperature furnace linings.

Moreover, thermal expansion characteristics of ceramics are pivotal in applications subjected to temperature fluctuations. The coefficient of thermal expansion (CTE) measures a material's tendency to expand when heated. Most technical ceramics exhibit lower CTE values compared to metals, generally ranging from 5 to 12 x 10-6/K for materials like alumina. This attribute minimizes the risk of thermal shock and cracking in products exposed to rapid temperature changes. Understanding these properties allows engineers to choose ceramics that not only suit the thermal requirements of their applications but also enhance durability and performance under varying operational conditions.

When selecting technical ceramics for specific industry applications, assessing chemical resistance is crucial. Different industries encounter various corrosive substances, necessitating materials that can withstand these challenges. For instance, the pharmaceutical and food industries require ceramics that resist stringent cleaning agents and sterilization processes, ensuring not only durability but also safety and compliance with health standards. In contrast, the petrochemical sector may prioritize resistance to high-temperature and aggressive chemicals, pushing the boundaries of material performance.

Understanding the unique chemical exposures in each industry allows engineers and purchasing managers to make informed decisions. Conducting thorough evaluations of the ceramic materials against relevant chemical exposure scenarios ensures that the selected ceramics will not degrade or react negatively when used in specific applications. By categorizing industries and their respective chemical challenges, stakeholders can streamline the selection process, ensuring longevity and reliability in their technical ceramics. This tailored approach ultimately enhances operational efficiency and reduces maintenance costs associated with material failure.

When selecting technical ceramics for industry applications, cost-effectiveness is a crucial factor that often determines the long-term viability of materials. According to a report by the Global Technical Ceramics Market, the sector is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2026, partly driven by the durability and unique properties of these ceramics. While the initial investment might be higher compared to traditional materials, the longevity and minimal maintenance requirements of technical ceramics can lead to significant cost savings over time. For instance, advanced ceramics are known to outperform metals in terms of wear resistance, leading to an extended lifecycle of components and reduced replacement frequency.

In industries such as aerospace and automotive, the integration of technical ceramics can yield impressive returns. Research from the Ceramic Materials Association indicates that using advanced ceramics in engine components can enhance fuel efficiency by up to 15%. This improvement not only lowers operational costs but also contributes to sustainability efforts by reducing emissions. Furthermore, technical ceramics exhibit excellent thermal stability, making them ideal for high-temperature applications, which opens up new avenues for innovation in fields where traditional materials may fail. As industries continue to prioritize performance alongside economy, the long-term benefits of investing in technical ceramics become increasingly clear.

| Industry | Type of Technical Ceramic | Key Benefits | Cost-Effectiveness (ROI) | Typical Applications |

|---|---|---|---|---|

| Aerospace | Silicon Nitride | High strength, lightweight, thermal stability | High initial investment but reduced maintenance costs | Turbine components, bearings |

| Electronics | Alumina | Electrical insulation, durability | Long lifespan leading to lower lifetime costs | Substrates, insulators |

| Medical | Zirconia | Biocompatibility, toughness | High upfront cost offset by durability in implants | Dental implants, surgical tools |

| Automotive | Titanium Diboride | Wear resistance, high hardness | Long-term savings on part replacements | Brake pads, wear components |

| Energy | Calcium Zirconate | Thermal shock resistance, chemical stability | Reduced operational costs due to lower downtime | Fuel cells, thermal barrier coatings |