Leave Your Message

Choosing the right kiln furniture can be challenging. Kiln furniture is essential for any ceramic artist or potter. It supports and holds pieces during firing. However, not all kiln furniture is the same. Different materials and designs serve various needs.

Understanding your specific requirements is crucial. Do you need durability, precision, or versatility? Often, artists overlook these details. They may choose kiln furniture based on price alone. This can lead to complications. For instance, using the wrong support can cause warping or even breakage.

Consider your firing temperature. The right kiln furniture should withstand heat. Look at materials like cordierite or alumina. Each has unique properties. Reflecting on your work can guide your choice. Take the time to evaluate what suits your needs best. Balancing practicality and creativity is key in this decision.

Kiln furniture plays a critical role in effective kiln operations. It includes shelves, props, and supports that hold ceramic pieces during firing. Choosing the right kiln furniture impacts the final product’s quality. For instance, improper support can lead to warping. It's essential to ensure that the furniture can withstand high temperatures without collapsing.

Each component of kiln furniture should be suited to specific materials and firing techniques. Some materials are more durable than others. Consulting with experts can be beneficial, but remember that there is no one-size-fits-all solution. Each kiln and its contents may require unique furniture types. Reflecting on your specific needs can often lead to better choices.

The arrangement of kiln furniture can also affect temperature distribution. Uneven spacing can cause hot spots. It's essential to think through the layout before beginning a firing cycle. Regular evaluation of your current setup is vital. Small adjustments can lead to significant improvements.

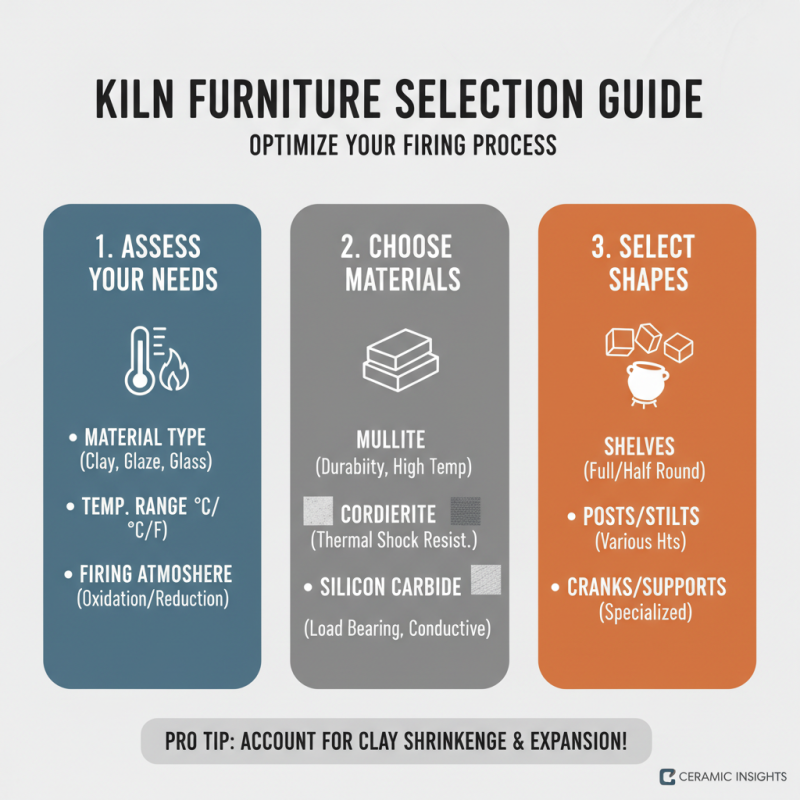

Choosing the right kiln furniture starts with understanding your specific firing needs. Different materials and shapes influence how items are supported during the firing process. If you work with ceramics, consider that clay bodies shrink and expand. The furniture must withstand these changes without warping or cracking.

Temperature is another crucial factor. High-fire ceramics often need more robust support. Conversely, low-fire applications can utilize lighter materials. Take time to explore various options, as what suits one project may not work for another. Each firing has its own demands, so don’t hesitate to experiment.

Assess your loading technique, too. Do you stack pieces tightly or leave spaces? This affects how the kiln furniture should be arranged. Too much pressure can cause breakage. Always reflect on past firings: what went wrong? This will guide improvements. A thoughtful approach can lead to better selections and results.

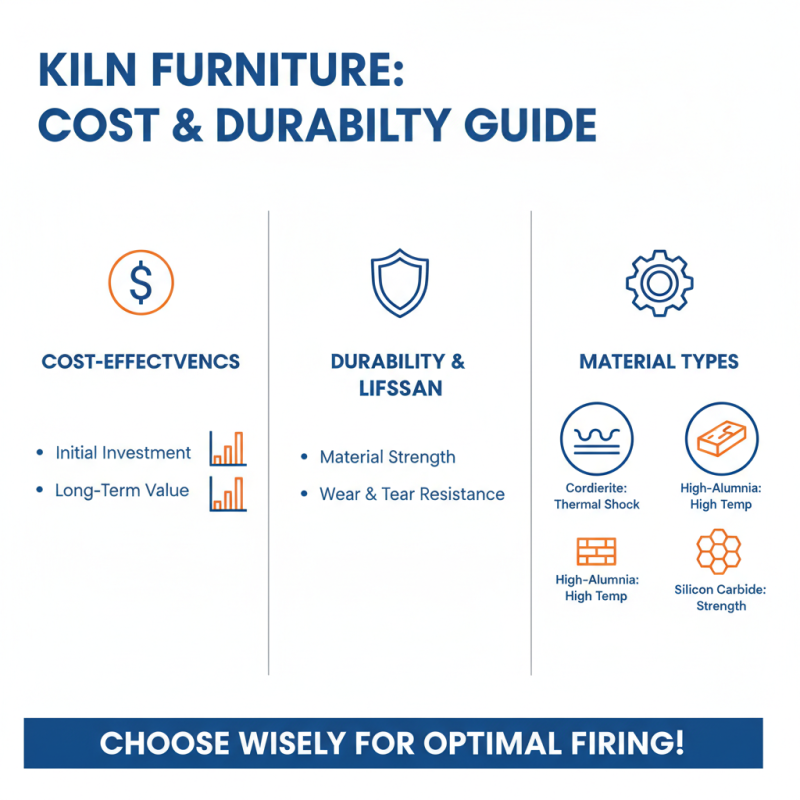

Choosing the right kiln furniture involves understanding materials essential for your firing process. Various types of kiln furniture are designed for specific needs. Common materials include cordierite, alumina, and silicon carbide. Each of these materials has distinct properties that affect performance.

Cordierite is popular for its thermal shock resistance. It can withstand rapid temperature changes, making it ideal for pottery. Reports indicate that cordierite can survive temperatures up to 1,250°C. However, it may crack under extreme conditions. Consider your firing temperature and load size before choosing cordierite.

Alumina, known for high thermal stability, is another option. It offers excellent durability, making it suitable for heavy loads. However, it is more expensive than other materials. If cost is a concern, weigh the potential risks.

Tips: Assess your kiln's environment. Take note of your firing temperatures and load types. This knowledge will guide your material choice.

Silicon carbide is robust and offers excellent thermal conductivity. It enhances firing efficiency but is heavier and more costly. This can impact handling. A careful evaluation of your needs is crucial to avoid unnecessary expenses. Remember, not every material suits every application.

When selecting kiln furniture, size and shape are crucial. Your kiln's dimensions will dictate what types of furniture fit. Measure the interior space accurately. Take note of the height, width, and depth. An ill-fitting shelf can lead to waste. If it's too large, it won’t fit; if it's too small, it won't support your work.

Consider the shape of your kiln furniture as well. Round shelves may fit better in cylindrical kilns, while rectangular ones suit box-shaped models. Assess your pieces carefully. Small adjustments can make a significant difference in performance. Experimenting with different configurations can yield surprising results. Don’t be afraid to rethink your approach. Sometimes, trial and error leads to the best solutions.

| Dimension | Recommended Size | Material Type | Shape | Application |

|---|---|---|---|---|

| Small | Up to 12 inches | Silicon Carbide | Rectangular | Small batch firing |

| Medium | 12-24 inches | Alumina | Square | Standard firing |

| Large | 24-36 inches | Fireclay | Round | Glaze firing |

| Extra Large | Over 36 inches | Cordierite | Custom | Production firing |

Choosing the right kiln furniture requires careful consideration of cost-effectiveness and durability. Kiln shelves, supports, and posts come in various materials and types. Each option has unique characteristics that affect performance. For instance, cordierite shelves offer good thermal shock resistance, but they may wear out faster in high-temperature settings.

Examining the cost is crucial. Higher initial costs don’t always mean better value. Some cheaper options may crack easily and require replacement sooner. This leads to more expense over time. It's essential to evaluate how often you fire your kiln and the types of projects you undertake. If you fire frequently, investing in durable options might save money in the long run.

Durability is a challenge. Some users notice that even reputable products don't hold up as expected. Sometimes, the surface can degrade or warp after several uses. This can compromise the quality of your work. Look for user reviews that mention longevity. Real-life experiences can shed light on potential issues. Balancing cost and durability ensures you make the best choice for your needs.