Leave Your Message

The selection of the right Corundum Mullite Sagger is critical for various applications in the ceramics and high-temperature materials industries. As noted in the latest market research report by MarketsandMarkets, the global ceramics market is expected to reach USD 300 billion by 2026, with a significant portion driven by the need for efficient and reliable high-temperature solutions. Corundum mullite saggers play a pivotal role in the production of advanced ceramics, offering superior thermal stability, mechanical strength, and resistance to chemical wear.

Recent studies have demonstrated that employing high-quality corundum mullite saggers can enhance production efficiency by up to 20%, resulting in lower production costs and improved product quality. The increasing demand for high-performance materials in industries such as aerospace, automotive, and electronics further emphasizes the need for precise selection of saggers tailored to specific thermal and mechanical requirements. Selecting the appropriate Corundum Mullite Sagger not only ensures optimal performance under high temperatures but also supports sustainable manufacturing practices through reduced energy consumption and waste.

Investing in the right Corundum Mullite Sagger represents a strategic decision for manufacturers seeking to optimize their production processes. With a thorough understanding of application-specific requirements and the advantages offered by various sagger designs, businesses can boost their operational efficiency and maintain a competitive edge in today's fast-paced market.

Corundum mullite saggers are essential components in high-temperature firing processes, particularly in ceramics and other refractory applications. Comprised primarily of alumina and silica, corundum mullite provides exceptional thermal stability, mechanical strength, and resistance to thermal shock. This makes it particularly suitable for use in kilns and furnaces, where it can withstand the rigorous demands of extreme heat while protecting the products being fired.

When selecting a corundum mullite sagger, it is crucial to understand the specific requirements of your application. Factors such as temperature range, the type of material being processed, and atmosphere conditions—whether oxidizing or reducing—play significant roles in determining the appropriate design and composition of the sagger. Additionally, considerations regarding the shape and size of the sagger will influence its capacity to hold and effectively insulate the items during the firing process, ensuring optimal performance and minimal defects in the final products.

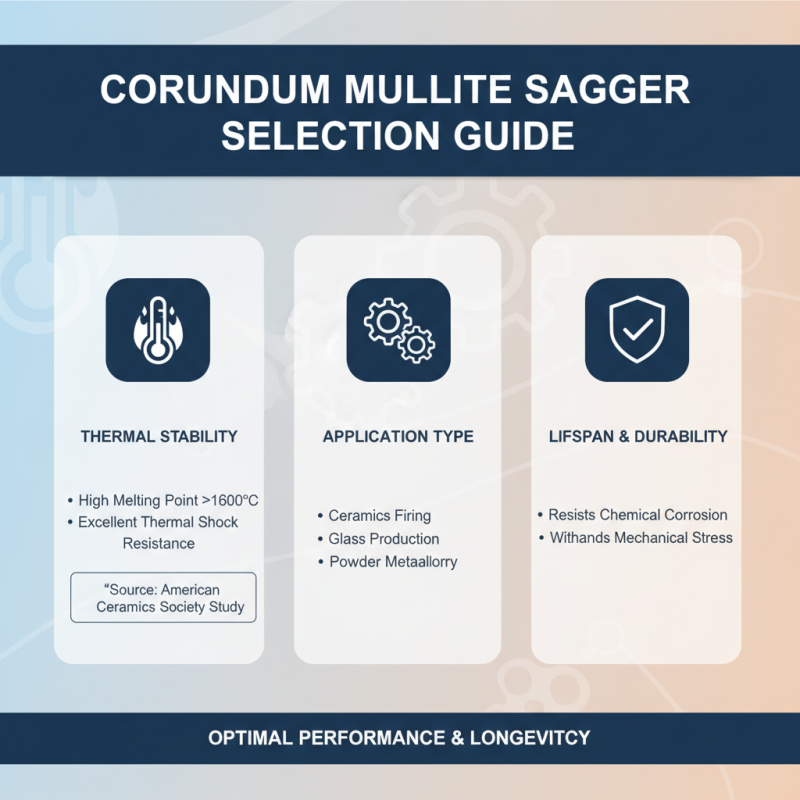

When selecting the right corundum mullite sagger for various applications, a few key factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the thermal stability of the sagger material. Corundum mullite has a high melting point and excellent thermal shock resistance, making it suitable for high-temperature environments commonly found in kiln operations. According to a study by the American Ceramics Society, saggers composed of corundum mullite can withstand temperatures exceeding 1600°C, which is essential for processes such as ceramics firing and glass production.

Another critical factor is the sagger's porosity. Low porosity is crucial in preventing the infiltration of unwanted materials and improving strength under load conditions. Research indicates that saggers with less than 10% porosity show significantly better mechanical properties, with a flexural strength that can reach up to 30 MPa. Additionally, manufacturers need to consider the sagger's geometry, as customized designs can enhance packing efficiency and reduce energy consumption during firing. Proper assessment of these factors can lead to substantial cost savings and improved product quality in high-temperature manufacturing processes.

When selecting the right corundum mullite sagger for specific applications, understanding the various types and their intended uses is crucial. Corundum mullite saggers are predominantly designed to withstand high temperatures and provide excellent thermal stability, making them ideal for use in ceramics, glass, and metal industries. According to industry reports, the thermal shock resistance of corundum mullite saggers can reach up to 1650°C, providing substantial durability in challenging environments.

Among the different types of saggers available, high-purity corundum mullite is often used for applications that require minimal contamination, such as advanced ceramics. Moreover, low-density mullite saggers are suitable for lightweight products, reducing the overall weight during handling and transportation while maintaining strength. Additionally, for industries focusing on energy efficiency, porous corundum mullite saggers are favored as they enhance the insulation properties of kilns, leading to lower energy consumption.

Tips: When choosing a sagger, always consider the maximum operating temperature of your application. For areas with rapid temperature fluctuations, select a sagger known for its superior thermal shock resistance. Regularly consult updated industry reports to stay informed about advancements in materials, which can enhance the operational efficiency and longevity of your equipment.

When choosing corundum mullite saggers for specific applications, evaluating their performance and longevity is crucial. Corundum mullite materials are known for their excellent thermal stability and mechanical strength, making them suitable for high-temperature applications. However, the actual performance can vary based on several factors, including temperature resistance, chemical durability, and load capacity. Understanding the specific needs of your process will help in selecting the right sagger and ensuring optimal performance.

**Tips:**

1. Conduct a thorough assessment of the operating environment to determine the temperature and chemical exposure levels. This information will guide you towards saggers with appropriate thermal and chemical resistance.

2. Opt for saggers with a robust construction that can withstand the physical demands of your application, including sufficient load-bearing capabilities.

Additionally, longevity is an important aspect when selecting saggers. Regular monitoring of wear and tear can prevent unexpected downtimes. Consider factors such as the number of cycles the sagger can endure and its resistance to thermal shock. Investing in quality corundum mullite saggers may yield better long-term performance and lower maintenance costs in the long run.

**Tips:**

1. Keep records of sagger usage and performance to help predict when replacements might be necessary.

2. Choose saggers that are easy to clean and maintain, as this will extend their lifespan and enhance performance.

When it comes to using corundum mullite saggers, proper maintenance is essential for ensuring their longevity and optimal performance. Regular inspections should be conducted to identify any signs of wear or damage, particularly after high-temperature applications. Keeping the sagger clean is crucial; any residual materials can lead to contamination in subsequent firings. It's recommended to use non-abrasive cleaning tools to maintain the integrity of the sagger's surface.

Tips for maintaining your sagger include avoiding sudden temperature changes, as this can cause thermal shock and lead to cracking. When stacking saggers, ensure they are adequately spaced to allow for even heat distribution, preventing hotspots that could compromise their structure. Additionally, storing saggers in a dry, temperature-controlled environment can minimize moisture absorption, which is vital for maintaining their durability.

Regular maintenance not only prolongs the life of corundum mullite saggers but also enhances the quality of the products they support. By adhering to these maintenance tips, you can optimize your sagger's function, ensuring consistent performance and reducing the risk of costly damages during critical processes.