Leave Your Message

Choosing the right refractory sagger for your industrial processes is critical to ensuring efficiency, durability, and optimal performance in high-heat environments. A refractory sagger, an essential component in industries such as ceramics, metal casting, and glass manufacturing, plays a pivotal role in protecting delicate products from excessive temperatures and ensuring consistent quality throughout the firing process.

In this guide, we will explore the key factors to consider when selecting a refractory sagger that meets your specific industrial needs. From evaluating the material composition to assessing the design and capacity of the sagger, making informed decisions can help enhance production outcomes and reduce costs. Whether you are upgrading existing equipment or venturing into new applications, understanding the nuances of refractory saggers will empower you to achieve superior results in your production line.

When selecting a refractory sagger for industrial applications, several key factors must be taken into account to ensure optimal performance and longevity. First and foremost, the operating temperature is crucial. Different refractories can withstand various temperature ranges, so it's essential to choose a sagger that aligns with the specific thermal requirements of your processes. This consideration not only affects the durability of the sagger but also impacts the quality of the products being fired.

Another critical factor is the chemical compatibility of the sagger material with the specific contents it will hold. Understanding the chemical interactions between the sagger and the materials being processed can prevent detrimental reactions that may lead to contamination or damage. Additionally, the physical properties of the sagger, such as its porosity and thermal shock resistance, should be evaluated. High porosity may allow for greater gas flow, which can be beneficial, while thermal shock resistance ensures that the sagger can withstand rapid temperature changes without cracking.

Finally, the design and size of the sagger should be tailored to fit the dimensions of the kilns and to accommodate the volume of materials being processed. Adequate sizing promotes efficient loading and unloading, while thoughtful design can enhance the overall efficiency of the firing process. By carefully considering these factors, you can select a refractory sagger that meets your industrial needs effectively.

| Factor | Description | Importance Level | Examples |

|---|---|---|---|

| Material Composition | Consider the type of raw materials used in construction for temperature and chemical resistance. | High | Silica, Alumina, Zirconia |

| Operating Temperature | Select saggers that can withstand the maximum temperature in your process. | High | Up to 1600 °C |

| Size and Shape | Ensure the sagger fits within your kiln and accommodates your products. | Medium | Custom shapes for specific product dimensions |

| Thermal Shock Resistance | Evaluate the ability to endure rapid temperature changes without cracking. | High | Alumina-based sagger types |

| Cost Efficiency | Balance between upfront costs and longevity of the sagger. | Medium | Comparison of various material options |

| Chemical Resistance | Consider exposure to chemicals and their effect over time on the sagger material. | High | Use in glass or ceramics applications |

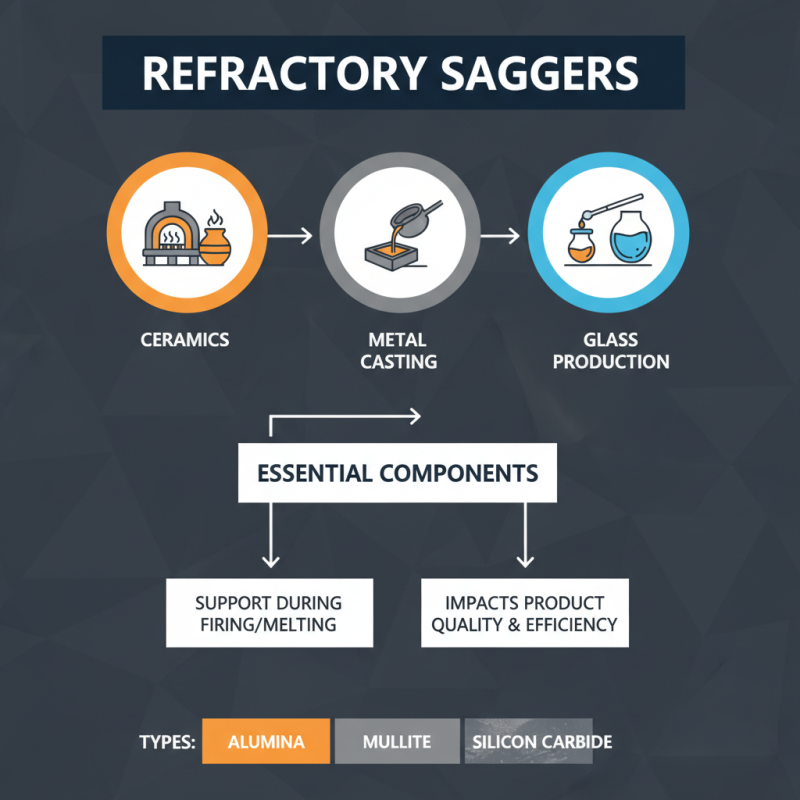

Refractory saggers are essential components in various industrial processes, particularly in ceramics, metal casting, and glass production. Their primary function is to provide support for refractory products during the firing or melting processes. The choice of refractory sagger significantly impacts both product quality and production efficiency. In the industry, there are various types of refractory saggers, each designed to meet specific operational needs.

One common type is the traditional clay-based sagger, which is often favored for its excellent thermal resistance and ability to withstand high temperatures. A report by the Refractory Manufacturer's Association indicated that clay-based materials can typically endure temperatures exceeding 1,600°C, making them suitable for applications in high-temperature kilns. Alternatively, advanced materials such as cordierite and mullite offer superior thermal shock resistance, which is crucial in processes where rapid temperature changes occur. Studies have shown that using cordierite saggers can enhance energy efficiency by up to 20%, reducing the overall operational costs in large-scale manufacturing environments.

Additionally, certain industries are gravitating towards customized refractory saggers that are engineered to address specific challenges. For instance, the glass industry often requires saggers with tailored dimensions and thermal properties to facilitate specific melting profiles. According to market research conducted by a leading materials consultancy, the demand for customized refractory solutions is expected to grow by 15% annually as industries seek to optimize their processes and improve product outcomes. This trend underscores the importance of choosing the right refractory sagger to align with the specific thermal and mechanical demands of each manufacturing process.

When selecting a refractory sagger, understanding the material composition is pivotal for optimizing performance in industrial applications.

Refractory saggers are primarily manufactured from various materials, including high alumina,

silica, and magnesia, each offering distinct thermal and mechanical properties.

According to a recent industry report, high alumina saggers display superior resistance to thermal shock and chemical corrosion, making them ideal for

environments with fluctuating temperatures. Their ability to withstand up to 1800°C allows for the effective handling of high-performance ceramics and glass.

Moreover, the choice of material can significantly influence the longevity and reliability of the sagger.

For instance, saggers produced from silica materials have lower thermal conductivity, which can be advantageous in energy conservation during firing processes.

However, they may lack the mechanical strength required in high-stress applications compared to their alumina and magnesia counterparts.

A comprehensive study by the International Ceramic Society indicated that saggers constructed with a blended composition of alumina and silica can provide a

balanced solution, enhancing both durability and thermal performance, thus extending the product lifespan and reducing operational costs.

Understanding these factors ultimately leads to more informed decisions that align with specific industrial requirements.

When selecting the right refractory sagger for industrial applications, temperature resistance is a crucial factor. Different industries have specific heat levels that materials must withstand. For instance, ceramics and glass industries often operate at temperatures ranging from 1000°C to 1700°C, making it essential to choose saggers that can endure such extreme conditions without deformation. According to a report by the Refractories Industry Association, materials typically used for saggers, such as alumina and zirconia, exhibit commendable resistance to thermal shock and high-temperature stability, ensuring reliability in these demanding environments.

In the metal casting sector, where temperatures can exceed 1500°C, the thermal performance of refractory saggers becomes even more significant. The use of lightweight, high-alumina materials helps reduce thermal conductivity, which is vital for maintaining efficient heating and preventing energy losses. Data from recent market studies indicate that the global demand for high-temperature resistant refractory materials has surged, underscoring the industry's reliance on advanced materials that can withstand prolonged exposure to intense heat and chemical interactions. Understanding these temperature requirements is paramount for optimizing production processes and enhancing product quality across various industrial applications.

When evaluating the cost-effectiveness of refractory saggers for large-scale production, it is essential to consider several key factors. First, the initial investment in refractory saggers can vary widely depending on material composition, design, and thermal resistance. However, understanding the long-term benefits they provide is crucial. A high-quality sagger may have a higher upfront cost but can lead to significant savings by reducing replacement frequency and minimizing downtime during production.

Additionally, energy efficiency plays a pivotal role in the cost-effectiveness of refractory saggers. High-performance saggers can help maintain consistent temperatures, thereby improving the overall efficiency of kilns and reducing energy consumption. By analyzing operational expenditures, businesses can better determine which refractory sagger aligns with their production needs and budget constraints. An investment in effective refractory materials not only boosts productivity but also enhances the overall quality of the end products, providing a competitive edge in the market.