Leave Your Message

In the realm of kiln applications, the significance of materials is underscored by the rising demand for efficient production processes and enhanced thermal management. Among the myriad of options available, the Cordierite Mullite Plate has emerged as a cornerstone for achieving high performance in various industrial settings. According to a recent industry report by MarketsandMarkets, the global market for advanced ceramics, which includes Cordierite materials, is projected to reach $179 billion by 2026, driven by their ability to withstand extreme temperatures and thermal cycling. The outstanding thermal shock resistance and low thermal expansion of Cordierite Mullite Plates make them an ideal choice for kilns, where consistent performance is critical. Furthermore, their lightweight nature contributes to energy savings, making them not only effective but also cost-efficient. This introduction sets the stage for exploring the superior qualities of Cordierite Mullite Plates that position them at the forefront of high-performance kiln solutions.

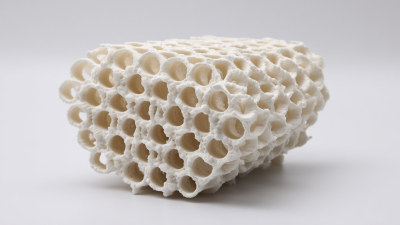

Cordierite mullite plates have gained recognition in the ceramics and kiln manufacturer sectors due to their exceptional thermal and mechanical properties. Known for their low thermal expansion coefficient, these materials significantly reduce the risk of thermal shock, making them ideal for high-temperature applications. According to a 2021 industry report from the Materials Research Society, cordierite mullite exhibits a thermal expansion coefficient of only 2.5 x 10⁻⁶/°C, which is substantially lower than traditional refractory materials. This characteristic ensures structural integrity during rapid temperature changes, enhancing the longevity of kiln equipment.

In addition to thermal stability, cordierite mullite plates offer remarkable resistance to chemical corrosion. Their composition allows them to withstand the harsh environments typically found in kiln applications, including exposure to acidic and alkaline substances. A study published by the American Ceramic Society found that cordierite mullite maintains up to 90% of its mechanical strength after prolonged exposure to corrosive agents, making it a reliable choice for industries focused on high-performance and sustainable practices.

**Tips:** When selecting materials for kiln applications, consider the specific temperature ranges and chemical exposures your equipment will face. Regular maintenance of kiln environments can prevent unexpected failures, prolonging the lifespan of your cordierite mullite components. It's crucial to consult with suppliers for detailed specifications to ensure the optimal choice for your specific needs.

Cordierite mullite plates have emerged as a vital material in high-performance kiln applications, primarily due to their exceptional thermal stability and thermal shock resistance. These plates can withstand extreme temperature fluctuations, making them ideal for environments where rapid heating and cooling occur. This characteristic is essential for kilns used in ceramics and metal processing, where thermal shocks can lead to material failure. By maintaining structural integrity under severe conditions, cordierite mullite plates help enhance the longevity and efficiency of kilns.

Tip: Regularly inspect the kiln's temperature control system to maximize the benefits of cordierite mullite plates. Proper temperature management can further reduce the risk of thermal shock.

Furthermore, the low thermal expansion coefficient of cordierite contributes to its ability to resist cracking and deformation under stress. This property is crucial for applications that require precision and reliability. As manufacturers seek materials that combine durability with exceptional performance, cordierite mullite plates stand out, providing a robust solution for high-temperature applications.

Tip: Consider conducting periodic thermal cycling tests on your kiln setup to evaluate the performance of the cordierite mullite plates and ensure they meet operational demands.

In comparing Cordierite Mullite to traditional materials used in kiln applications, it is essential to recognize the significant advantages that Cordierite Mullite offers. Traditional kiln materials often struggle with thermal shock and sustained high temperatures, leading to premature failure and increased maintenance costs. The thermal stability and lower thermal expansion coefficient of Cordierite Mullite enhance its performance by resisting distortion and cracking under fluctuating thermal conditions. This quality not only prolongs the lifespan of the kiln components but also optimizes energy efficiency during operation.

Moreover, recent studies highlight the impact of traditional brick kilns on environmental issues, including heavy metal emissions and their subsequent migration in sewage sludge. The transition to Cordierite Mullite can mitigate such risks, as its properties support cleaner combustion and lower emissions. Furthermore, the material's performance in high-temperature environments aligns with the industry's shift towards sustainable practices, particularly in contexts like the ceramic tile sector, where competitive sustainability assessments are on the rise. By prioritizing materials like Cordierite Mullite, kiln technologies can enhance both performance and environmental stewardship, paving the way for more responsible industrial practices.

Cordierite mullite plates

are increasingly recognized for their invaluable role in high-temperature kiln operations. These plates exhibit exceptional thermal stability and a low thermal expansion coefficient, making them ideal for environments where rapid temperature changes occur. Their ability to withstand extreme thermal shock reduces the risk of cracking and ensures the consistent performance of kilns during intense operations.

Moreover, the lightweight nature of cordierite mullite plates contributes significantly to energy efficiency in kiln applications. By minimizing the overall weight of kiln linings, they facilitate quicker heating and cooling cycles, which can enhance production efficiency. Their excellent insulating properties also help in reducing heat loss, allowing for better energy management. As a result, industries employing cordierite mullite plates can achieve significant cost savings while maintaining high performance standards in their kiln operations.

Innovations in Cordierite Mullite design are paving the way for enhanced kiln performance, particularly in high-temperature applications. The focus is on optimizing thermal shock resistance and mechanical strength, which are critical for the demanding environment of kilns. Advanced manufacturing techniques, such as improved extrusion processes and the use of high-purity raw materials, are enabling the production of Cordierite Mullite plates that significantly outperform traditional materials. These advancements not only prolong the lifespan of kiln components but also contribute to more efficient energy consumption, ultimately lowering operational costs.

**Tip:** When selecting Cordierite Mullite materials for your kiln, consider the specific thermal and mechanical requirements of your application. Investing in high-quality materials can lead to substantial long-term savings in maintenance and downtime.

Moreover, future trends indicate a push towards integrating smart technologies within Cordierite Mullite plates. The incorporation of sensors to monitor temperature and structural integrity can provide real-time data, enhancing operational efficiency and safety. These innovations represent a significant leap forward in kiln technology, making Cordierite Mullite a cornerstone for industries looking to stay at the forefront of performance and sustainability.

**Tip:** Keep an eye on emerging technologies that complement Cordierite Mullite products, such as advanced coating techniques and structural health monitoring systems, to further elevate your kiln's performance.

| Feature | Description | Impact on Kiln Performance |

|---|---|---|

| High Temperature Resistance | Cordierite mullite plates can withstand extreme temperatures up to 1400°C. | Enhanced longevity and reduced maintenance intervals for kilns. |

| Thermal Shock Resistance | Designed to handle rapid temperature changes without cracking. | Improved efficiency and reduced downtime during production cycles. |

| Lightweight | Significantly lighter than other refractory materials. | Decreased energy consumption for kiln operations due to lower mass. |

| Low Thermal Conductivity | Excellent insulating properties reduce heat loss. | Enhanced energy efficiency leading to cost savings. |

| Chemical Resistance | Resistant to corrosive kiln atmospheres. | Increased lifespan of kiln components and reduced replacement costs. |