Leave Your Message

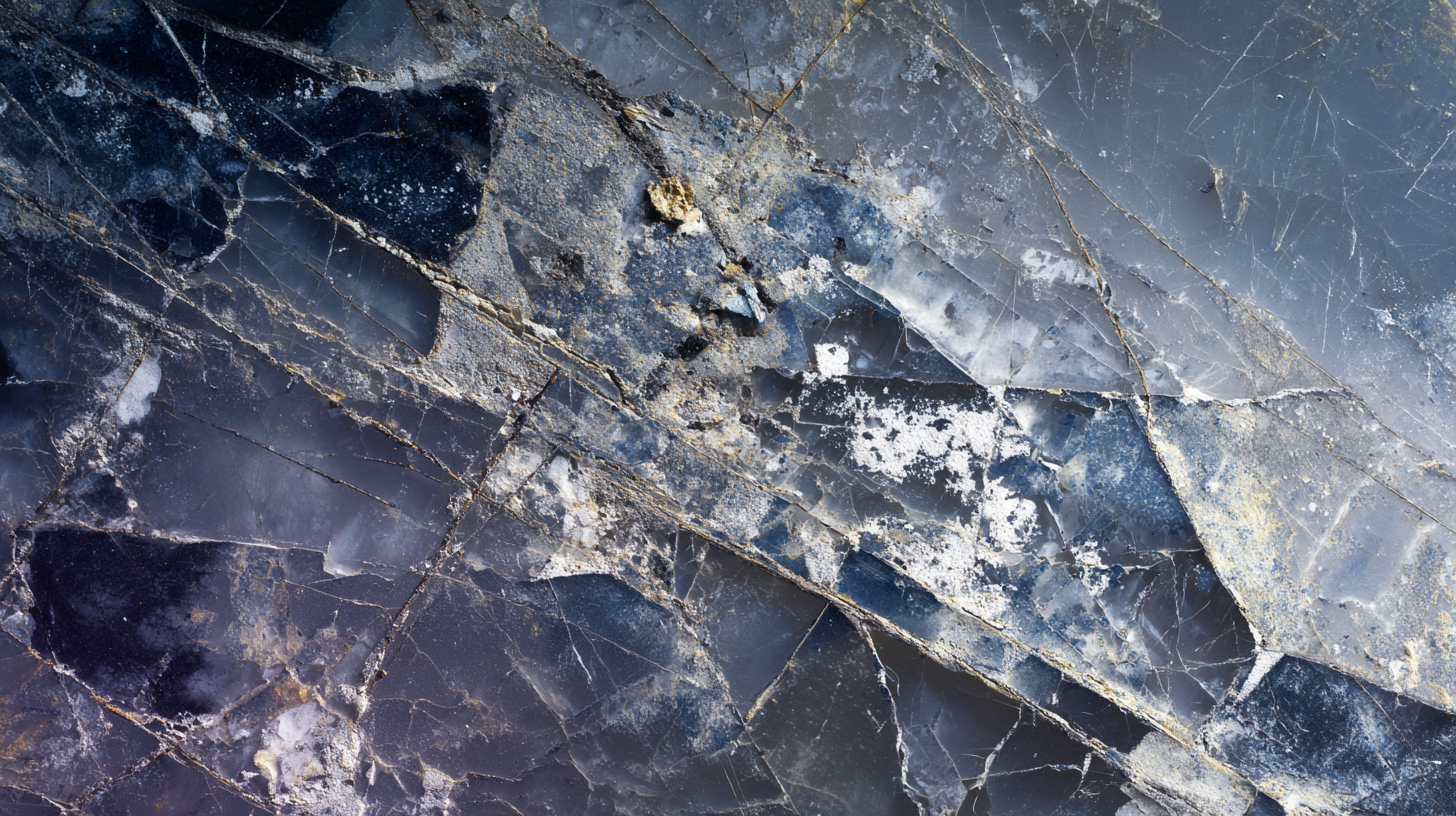

The Corundum Mullite Plate has gained significant attention in high-temperature applications due to its exceptional thermal and mechanical properties. In industries such as aerospace, ceramics, and metallurgy, the demand for materials that can withstand extreme temperatures while maintaining structural integrity is critical. According to a recent report by the Global Industry Analysts, the market for advanced ceramics, including Corundum Mullite Plates, is projected to reach $104 billion by 2026, reflecting a compound annual growth rate of 6.5%. The unique composition of corundum and mullite not only enhances the plate's thermal shock resistance but also improves its corrosion resistance, making it an ideal choice for furnace linings and kiln furniture. As industries increasingly require materials that promote energy efficiency and sustainable practices, the Corundum Mullite Plate stands out as a leading solution in the realm of high-temperature applications.

Corundum mullite plates are essential in high-temperature applications due to their unique combination of properties. One of the most significant advantages is their exceptional thermal stability. These plates can withstand extreme temperatures without deforming or breaking down, making them ideal for use in furnaces, kilns, and other high-heat environments. Their ability to maintain structural integrity under thermal stress is crucial for industries that rely on high-performance materials.

In addition to thermal stability, corundum mullite plates exhibit low thermal conductivity, which helps in energy conservation. This property allows them to act as efficient insulators, minimizing heat loss and thereby reducing energy costs in industrial processes. Furthermore, these plates possess excellent resistance to chemical corrosion, allowing them to endure aggressive environments without degrading. Their durability and resistance to thermal shock also contribute to a longer lifespan, reducing the frequency of replacements and maintenance efforts in demanding applications. Overall, the key properties of corundum mullite plates make them indispensable for industries operating at high temperatures.

| Property | Value | Significance |

|---|---|---|

| Service Temperature | 1400°C - 1600°C | suitable for high-temperature applications |

| Thermal Conductivity | 5-7 W/m·K | efficient heat transfer capabilities |

| Chemical Resistance | Excellent | resists corrosion from molten metals and slags |

| Mechanical Strength | High | withstands thermal shock and mechanical stress |

| Density | 2.8 - 3.2 g/cm³ | provides structural stability |

Corundum mullite plates are increasingly valued in high-temperature applications due to their superior thermal stability and resistance to thermal shock. These plates are composed of a unique combination of alumina (Al₂O₃) and silica (SiO₂), allowing them to withstand extreme temperatures that can reach up to 1600°C. A study by the International Journal of Materials Science noted that corundum mullite exhibits a thermal expansion coefficient of approximately 5.2 x 10⁻⁶/°C, which minimizes the risk of cracking under sudden thermal changes.

Corundum mullite, a composite of corundum and mullite, demonstrates superior thermal stability and mechanical strength when compared to traditional refractory materials like fireclay and high alumina bricks. This enhanced performance is primarily due to its unique microstructure, which offers better resistance to thermal cycling and dimensional stability under high-temperature conditions. In industrial applications, such as steelmaking and ceramics, corundum mullite plates can withstand extreme thermal shock and harsh environments, reducing the risk of structural failure.

When juxtaposed with traditional refractory materials, the advantages of corundum mullite become even more apparent. Traditional refractories often struggle with issues like shrinkage and cracking at elevated temperatures, leading to increased maintenance and downtime. In contrast, corundum mullite plates maintain their integrity under prolonged high temperatures, thereby increasing operational efficiency and lifespan. Additionally, their lower thermal conductivity helps in energy conservation, making them a more economically viable choice in the long run for industries reliant on high-temperature processes.

Corundum mullite plates have become increasingly essential in high-temperature applications across various industries, notably aerospace and ceramics. In the aerospace sector, where components must withstand extreme temperatures while maintaining structural integrity, corundum mullite’s unique thermal properties make it an ideal choice. Its high melting point and excellent thermal shock resistance ensure that critical parts can perform reliably, reducing the risk of failure during flight.

In the ceramics industry, corundum mullite plates are utilized in manufacturing processes that demand durability and stability. These plates serve as substrates for kiln furniture, allowing for even heat distribution and minimizing warping or distortion during firing. Their resistance to thermal expansion and exceptional mechanical strength also make them suitable for applications involving chemical reactions and thermal cycling, further enhancing their versatility in demanding environments. By integrating corundum mullite plates into their operations, industries can achieve improved performance and efficiency in high-temperature applications.

Corundum mullite plates are increasingly recognized for their cost-effectiveness and durability in extreme high-temperature applications. According to a report by the Advanced Materials Research Journal, the thermal stability of corundum-mullite composites allows them to maintain strength and structural integrity at temperatures exceeding 1600°C. This exceptional thermal resilience translates to lower replacement costs and reduced downtime in manufacturing environments, making them a smart long-term investment.

Furthermore, industry studies suggest that corundum mullite exhibits a lower thermal expansion coefficient compared to traditional materials, which minimizes the risk of thermal shock and cracks under severe conditions. This characteristic not only extends the lifespan of the components but also enhances operational reliability. A recent market analysis indicated that industries leveraging corundum mullite have reported a 20-30% increase in productivity due to fewer maintenance interruptions, illustrating the significant financial advantages and operational efficiencies gained from utilizing these advanced materials in high-temperature settings.