Leave Your Message

In recent years, the demand for high-performance materials has surged across various industrial sectors, leading to a significant interest in Technical Ceramics. According to a report by Market Research Future, the global technical ceramics market is projected to reach USD 133.1 billion by 2027, growing at a CAGR of 6.8%. This substantial growth can be attributed to the unique properties of Technical Ceramics including high wear resistance, exceptional thermal stability, and superior electrical insulation.

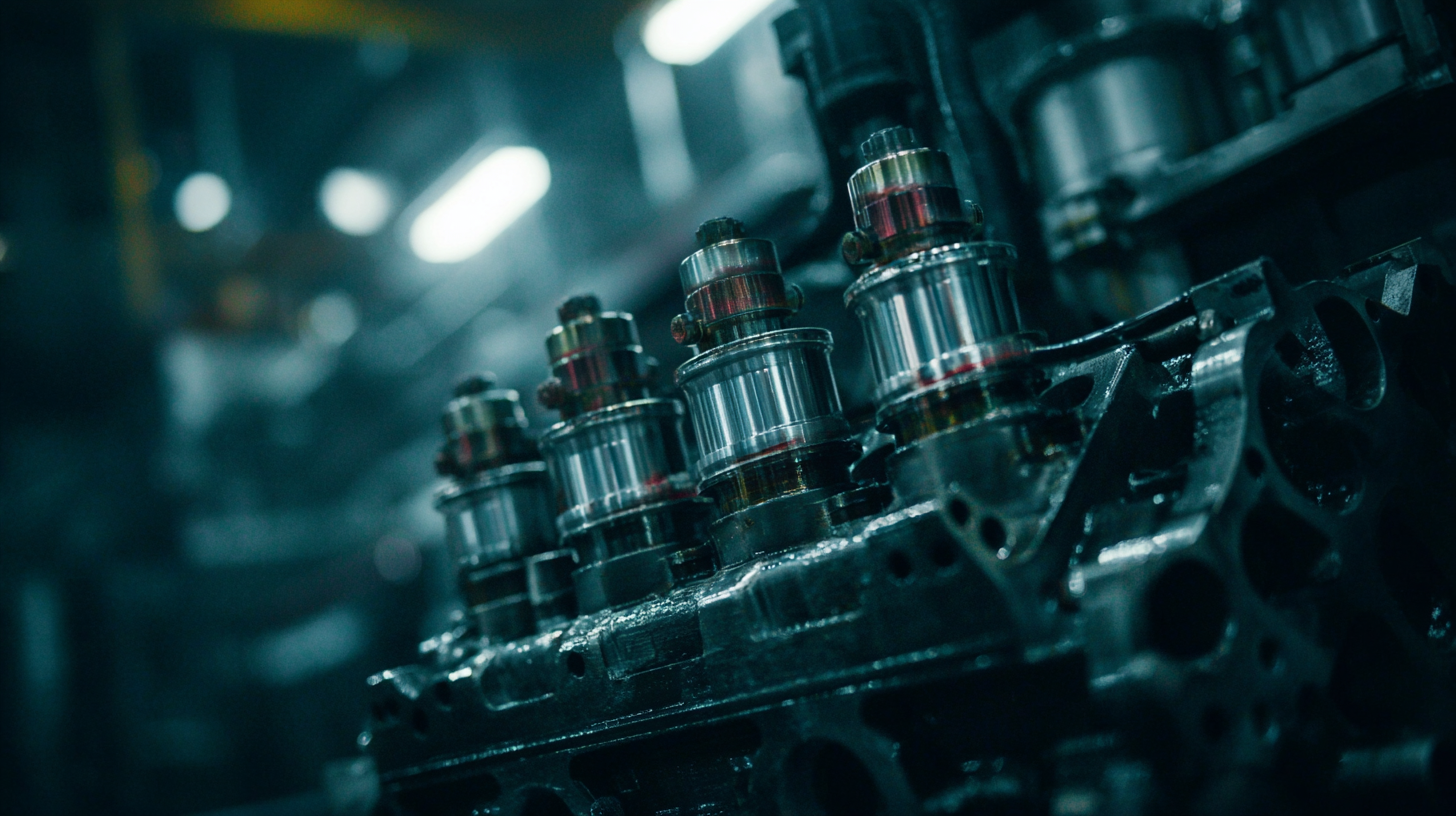

Industries such as aerospace, automotive, and electronics are increasingly harnessing these advanced materials to enhance product performance and durability. By understanding the specific applications and benefits of Technical Ceramics, manufacturers can leverage their potential to innovate modern industrial processes, thus driving efficiency and sustainability in operations. This article aims to explore effective strategies to incorporate Technical Ceramics into contemporary manufacturing practices, ensuring competitive advantage in an increasingly challenging market landscape.

Technical ceramics play a crucial role in modern industrial applications due to their unique mechanical and electrical properties. These materials are not only robust and durable but also exhibit excellent resistance to extreme temperatures and corrosive environments. As industries evolve, the demand for advanced ceramics, particularly in electrical components, is forecasted to grow significantly over the coming years. This trend emphasizes the need for a deeper understanding of the fundamental properties of technical ceramics, which can be harnessed to innovate and improve various industrial processes.

Technical ceramics play a crucial role in modern industrial applications due to their unique mechanical and electrical properties. These materials are not only robust and durable but also exhibit excellent resistance to extreme temperatures and corrosive environments. As industries evolve, the demand for advanced ceramics, particularly in electrical components, is forecasted to grow significantly over the coming years. This trend emphasizes the need for a deeper understanding of the fundamental properties of technical ceramics, which can be harnessed to innovate and improve various industrial processes.

Tips for utilizing technical ceramics effectively include focusing on material selection based on specific application needs, incorporating advanced manufacturing techniques such as 3D printing, and staying updated on ongoing engineering advancements in ceramic materials. Additionally, exploring the benefits of modifying ceramics, like enhancing mechanical properties with additives such as zirconium oxide, can lead to breakthroughs in performance and application versatility.

With the continuous development in the capabilities of technical ceramics, industries must proactively adapt to leverage these materials for sustainable and efficient manufacturing processes. Understanding the fundamentals of how different ceramic properties can be manipulated will be key in driving innovation and meeting future industrial challenges.

Technical ceramics are increasingly recognized for their remarkable properties that significantly enhance industrial performance. Among their key advantages are high-temperature resistance, superior hardness, and excellent chemical stability. According to a report by MarketsandMarkets, the global technical ceramics market is projected to grow from $10.2 billion in 2021 to $14.8 billion by 2026, driven by demand in automotive, aerospace, and electronics applications. These materials are capable of withstanding extreme conditions, making them ideal for components such as insulators and cutting tools.

Tips for selecting the right technical ceramic for your application include assessing the specific properties required, such as thermal conductivity and wear resistance. Utilizing ceramics that provide low friction coefficients, like silicon nitride, can significantly improve the lifespan of mechanical components. Moreover, incorporating ceramics into composite materials can enhance strength and reduce weight, leading to improved operational efficiency across various industrial sectors.

Another vital consideration is the manufacturing process for technical ceramics. Advanced techniques like additive manufacturing can allow for more complex geometries and increased flexibility in design, ultimately contributing to more innovative solutions in industrial applications. Evaluating research and development reports, such as those from the American Ceramic Society, can provide insights into emerging materials and technologies that further leverage the performance benefits of technical ceramics.

The use of technical ceramics in manufacturing has seen a remarkable surge in recent years, driven by their unique properties such as high thermal resistance, mechanical strength, and chemical stability. According to a report, the global technical ceramics market is projected to grow significantly, increasing from USD 105.54 billion in 2025 to an estimated USD 162.22 billion by 2033. This growth is further boosted by innovations like additive manufacturing and the development of advanced ceramics and nanoceramics, which are making strides in various sectors, including medical implants and semiconductor production.

Innovative applications of 3D printing technologies are reshaping the landscape of technical ceramics. Recent advancements in fabricating porous thermal insulating ceramics have proven to enhance thermal insulation properties, enabling industries to improve energy efficiency and reduce costs. As manufacturers continue to explore the potential of these materials, collaborative efforts are emerging, evidenced by conversations with industry leaders focusing on the capabilities of ceramic additive manufacturing. The technical ceramics sector is not just poised for growth but is also set to redefine manufacturing standards across industries, thanks to a combination of material science breakthroughs and strategic market transformations.

Integrating technical ceramics into modern production lines requires a thoughtful approach that balances innovation with practical application. First and foremost, manufacturers should conduct a comprehensive assessment of their production needs to identify areas where technical ceramics can offer advantages, such as improved wear resistance, higher thermal stability, and reduced weight. It's essential to collaborate closely with material scientists and engineers during this evaluation to understand the specific properties of various ceramic materials and their compatibility with existing processes.

Once potential applications are identified, best practices in the integration process must be implemented. This includes investing in specialized equipment and tooling designed for working with ceramics, as these materials often require different handling techniques compared to traditional metals or polymers. Additionally, training staff on the unique characteristics of technical ceramics is crucial to minimize risks during production. Regular maintenance and monitoring of ceramic components can further enhance performance and durability, ensuring that the integration of technical ceramics leads to enhanced efficiency and productivity on the production line.

The evolving role of technical ceramics in engineering solutions is underpinned by their exceptional properties that meet the demanding requirements of modern industrial applications. As industries pursue higher efficiency and sustainability, technical ceramics have emerged as a viable alternative to traditional materials, thanks to their high thermal stability, corrosion resistance, and mechanical strength. These characteristics make them ideal for use in sectors such as aerospace, automotive, and electronics, where performance and reliability are critical.

Looking ahead, we can anticipate significant trends shaping the future of technical ceramics. Innovations in 3D printing and additive manufacturing are set to revolutionize how these materials are produced, enabling complex geometries and reducing waste. Furthermore, advancements in nanotechnology may enhance the properties of technical ceramics, leading to even lighter, stronger, and more heat-resistant materials. As interdisciplinary approaches increase in engineering fields, the integration of technical ceramics into hybrid materials will further expand their applications, fostering cutting-edge solutions that address the challenges of tomorrow's industries.