Leave Your Message

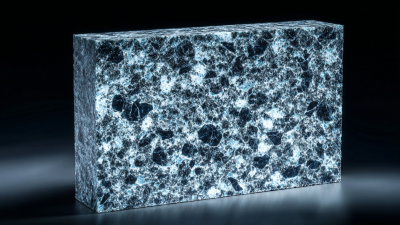

In the realm of manufacturing, the choice of materials and equipment can significantly influence productivity and product quality. One pivotal component often overlooked is the Refractory Sagger, a crucial item used in high-temperature processes to hold and protect ceramic products. John Smith, a renowned expert in the refractory industry, emphasizes, "Investing in high-quality refractory saggers is not just a choice; it's a vital strategy for manufacturers striving for excellence." This statement underlines the necessity of prioritizing these essential tools.

High-quality refractory saggers are designed to withstand extreme temperatures and harsh environments, directly impacting the efficiency and durability of the manufacturing process. Ignoring the quality of saggers can lead to increased failure rates, costly downtime, and ultimately, compromised product integrity. As we delve further into this article, we will explore the various reasons why investing in superior refractory saggers is not merely beneficial but essential for ensuring your manufacturing success is sustainable and profitable.

High-quality refractory saggers play a crucial role in enhancing the efficiency and quality of manufacturing processes, particularly in industries such as ceramics and metallurgy. According to a report by ResearchAndMarkets, the global refractory materials market is projected to grow at a CAGR of 3.8% from 2020 to 2025. The demand for superior refractory saggers is driven by their ability to withstand extreme temperatures, minimize thermal shock, and reduce contamination during production. These qualities ensure that the final products meet stringent quality standards, leading to increased customer satisfaction and market competitiveness.

High-quality refractory saggers play a crucial role in enhancing the efficiency and quality of manufacturing processes, particularly in industries such as ceramics and metallurgy. According to a report by ResearchAndMarkets, the global refractory materials market is projected to grow at a CAGR of 3.8% from 2020 to 2025. The demand for superior refractory saggers is driven by their ability to withstand extreme temperatures, minimize thermal shock, and reduce contamination during production. These qualities ensure that the final products meet stringent quality standards, leading to increased customer satisfaction and market competitiveness.

Moreover, investing in high-quality saggers can significantly improve operational efficiency. A study conducted by the International Journal of Advanced Manufacturing Technology indicates that using premium refractory materials can decrease production downtime by up to 25%. This reduction is attributed to fewer incidents of material failure and the extended lifespan of equipment, resulting in cost savings and better resource allocation for manufacturers. By prioritizing the use of high-quality refractory saggers, companies can ensure consistent production output and contribute to sustainable manufacturing practices.

The quality of refractory saggers plays a critical role in production efficiency within the manufacturing sector. According to a report by the Refractory Industry Association, high-quality refractory materials can enhance operational capabilities by up to 20%, significantly reducing downtime and material waste. Poor-quality saggers, conversely, may lead to early failures, resulting in costly interruptions and reduced productivity. A study by TechNavio highlights that manufacturers who invest in superior saggers can achieve up to 15% higher energy efficiency, translating to substantial cost savings over time.

**Tips:** To ensure optimal performance, always source refractory saggers from reputable suppliers who adhere to industry standards. Regular maintenance and inspections can also prolong the lifespan of saggers, preventing unexpected breakdowns. Training your staff on the handling and usage of these materials will further minimize damage during operations.

Investing in high-quality refractory saggers is not just a matter of expense; it's a strategic decision that impacts overall production outcomes. As outlined in the Market Research Future report, companies adopting premium refractory solutions have reported up to a 30% improvement in finished product quality. By prioritizing sagger quality, manufacturers can foster a more efficient production environment, ultimately paving the way for long-term success.

Investing in high-quality refractory saggers can significantly enhance manufacturing efficiency and reduce long-term costs. According to a recent report by the Refractory Industry Association, facilities that utilize durable saggers report a 30% reduction in replacement costs over a five-year period compared to those using lower-quality options. This reduction stems from the increased longevity and performance of high-quality refractory materials that withstand extreme temperatures and harsh industrial conditions, ultimately leading to fewer downtimes and maintenance needs.

Furthermore, a study conducted by Global Market Insights found that companies investing in superior saggers experience an uptick in product quality and yield, with an average improvement of 15% in end-product consistency. This increase in quality not only enhances customer satisfaction but also reduces material wastage, translating to substantial financial savings. The initial investment in quality refractory saggers, therefore, proves to be a strategic decision that pays dividends in operational efficiency and cost-effectiveness, reinforcing the idea that quality should not be compromised for short-term gains.

In the manufacturing sector, the significance of material selection cannot be overstated, particularly regarding high-performance refractory saggers. These components are essential for maintaining product quality during high-temperature processes. Investing in high-quality refractory saggers ensures not only durability but also enhances energy efficiency and reduces operational costs. As the global market continues to evolve, manufacturers must prioritize materials that can withstand extreme conditions while minimizing environmental impact.

**Tips for Material Selection:**

1. Evaluate the thermal stability and corrosion resistance of refractory materials to ensure longevity.

2. Consider lightweight options, such as high-entropy alloys, which can significantly improve performance and efficiency in demanding applications.

Furthermore, with the ongoing push towards sustainable practices, decarbonization solutions using thermal energy storage are becoming increasingly vital. Manufacturers can benefit from innovative designs that harness thermal energy efficiently, ultimately leading to a reduced carbon footprint. Embracing advancements in material science not only improves manufacturing processes but also aligns with global sustainability goals, creating a competitive edge in today’s market.

| Property | High-Quality Refractory Saggers | Standard Refractory Saggers |

|---|---|---|

| Service Temperature (°C) | 1400 | 1300 |

| Thermal Shock Resistance | Excellent | Good |

| Chemical Resistance | High | Moderate |

| Durability (Cycles) | 500+ | 300+ |

| Weight (kg) | 5.0 | 5.2 |

| Cost (per unit) | $150 | $100 |

Investing in high-quality refractory saggers is a critical component for achieving superior product quality and consistency in manufacturing processes, particularly in industries like ceramics and metal casting. According to a report by Freedonia Group, the global market for refractory materials is expected to grow at an annual rate of 3.7%, driven by the increasing demand for durable and efficient products. High-quality saggers, which are essential for protecting goods during high-temperature firing processes, ensure uniform heating and reduce the risk of defects in the final product.

Moreover, consistency in product quality is paramount in maintaining competitive advantage. A study conducted by the International Journal of Advanced Manufacturing Technology indicates that the use of premium refractory saggers results in a 15% reduction in defects compared to lower-quality alternatives. This enhancement not only leads to improved customer satisfaction but also minimizes waste and production costs. By prioritizing quality in saggers, manufacturers can significantly strengthen their overall operational efficiency and product reliability.