Leave Your Message

Zirconia Ceramic has emerged as a leading material in the manufacturing sector due to its exceptional mechanical properties and superior wear resistance. According to a report by Grand View Research, the global zirconia ceramic market is expected to reach USD 2.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This surge is largely attributed to the material's ability to withstand high-temperature environments while maintaining structural integrity.

However, to fully leverage the benefits of Zirconia Ceramic in various applications, manufacturers must implement strategies that enhance its durability. Drawing on expert insights, this blog will present seven essential tips aimed at maximizing the lifespan and performance of Zirconia Ceramic within your manufacturing processes, ensuring optimal results and longevity in a competitive landscape.

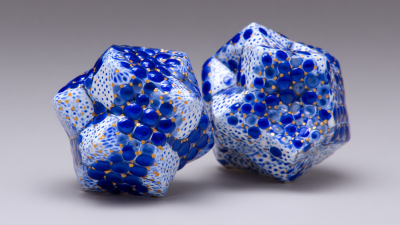

Zirconia ceramic is renowned for its exceptional strength and durability, making it a popular choice in various manufacturing processes. Understanding the unique properties of zirconia is crucial for enhancing its performance. One of the most notable characteristics of zirconia is its high fracture toughness, which allows it to resist chipping and cracking under stress. This property is a result of its monoclinic-to-tetragonal phase transformation that occurs when subjected to stress, effectively increasing its resilience.

Additionally, zirconia exhibits remarkable chemical stability and corrosion resistance. This makes it suitable for applications in harsh environments, where other materials may fail. By incorporating advanced manufacturing techniques, such as precision milling and sintering, manufacturers can further enhance the structural integrity of zirconia components. Proper handling and the use of suitable finishing processes are also essential to maintain its durability. Understanding these properties and implementing best practices in the manufacturing process will ensure that the advantages of zirconia ceramic are fully realized, ultimately leading to longer-lasting products.

When working with zirconia ceramic components, proper surface preparation is crucial for maximizing durability and ensuring optimal performance in various manufacturing processes. The first step in this process is to meticulously clean the surfaces to remove any contaminants such as oils, dust, or other residues. Using ultrasonic cleaning methods can be highly effective, as it allows for a thorough removal of particles from intricate geometries without causing damage to the substrate. Following this, a careful assessment of the surface roughness is essential. Achieving the right texture can significantly enhance bonding capabilities with other materials, contributing to the overall longevity of the final product.

In addition to cleaning, the use of appropriate grinding and polishing techniques is vital in preparing zirconia surfaces. Employing diamond abrasives ensures a fine finish, which not only improves aesthetic appeal but also reduces the risk of micro-cracking. Incorporating a controlled etching process can further enhance the surface characteristics, increasing the surface energy and promoting better adhesion during subsequent assembly or coating stages. By integrating these best practices into your manufacturing workflow, the durability and functional performance of zirconia ceramic components can be significantly improved, leading to more reliable products in the long run.

Optimizing sintering techniques is crucial for enhancing the strength and lifespan of zirconia ceramics, particularly in manufacturing processes where durability is paramount. Sintering involves heating the zirconia material to a temperature just below its melting point, facilitating the densification process. According to a research report from the American Ceramic Society, optimizing sintering temperatures within the range of 1450°C to 1550°C can significantly increase the material’s flexural strength, which can reach up to 1200 MPa.

Moreover, the application of controlled atmospheres during the sintering process has been shown to reduce the formation of undesirable phases within the zirconia structure. A study published in the Journal of Materials Science highlighted that the incorporation of yttria-stabilized zirconia (YSZ) can further improve thermal stability and wear resistance, reducing failure rates in high-stress applications by over 30%. By leveraging precise sintering methods and understanding the effects of additives, manufacturers can effectively enhance the mechanical properties and longevity of Zirconia ceramics, ensuring better performance in demanding environments.

Effective quality control measures are paramount in the manufacturing of zirconia ceramics, especially as advancements in powder-based additive manufacturing become increasingly prevalent. These processes allow manufacturers to create intricate components with high precision. However, to maximize the durability and performance of zirconia parts, implementing robust quality control protocols is essential. Regular monitoring of the material properties, such as density and particle size distribution, ensures that the powder utilized meets the required standards, which directly impacts the final product's quality.

One effective tip is to incorporate systematic testing throughout the production process. This might include evaluating the internal fit and marginal adaptation of zirconia crowns to ensure they meet strict tolerances, which have proven to be more accurate when compared to traditional milling techniques. Moreover, utilizing advanced characterization methods can help in assessing the structural integrity of the final products, allowing for continuous improvement in manufacturing practices. By following these steps, manufacturers can enhance the longevity and reliability of zirconia components, ensuring they stand the test of time in demanding applications.

Zirconia ceramic has gained considerable attention in manufacturing due to its exceptional mechanical properties and resistance to wear and corrosion. However, maximizing its durability can significantly enhance the efficiency and lifespan of products that utilize this material. Innovative coatings and treatments play a pivotal role in extending the longevity of zirconia ceramics. Recent studies show that applying advanced surface treatments, such as thermal spray coatings, can improve abrasion resistance by up to 50%, making zirconia ceramics even more suitable for high-stress environments.

Additionally, the integration of nano-coatings has shown promising results in enhancing the surface hardness of zirconia. According to a report by the Journal of the European Ceramic Society, the introduction of nano-coatings can lead to an increase in hardness levels up to 20%, thus reducing the likelihood of fracturing during operational stress. Industries utilizing zirconia in applications ranging from dental prosthetics to aerospace components can benefit substantially from these advancements. By prioritizing the implementation of innovative coatings and treatments, manufacturers can effectively prolong the service life of zirconia ceramics, resulting in lower replacement costs and improved performance reliability.