Leave Your Message

The manufacturing industry is continually evolving, driven by innovations that enhance efficiency and product quality. One such advancement is the use of Zirconia Ceramic, which has gained substantial traction due to its remarkable properties, including high strength, toughness, and resistance to wear and corrosion. According to a report by MarketsandMarkets, the global zirconia ceramics market is projected to grow from $1.12 billion in 2020 to $1.78 billion by 2025, reflecting an impressive CAGR of 9.5%. This growth underscores the increasing adoption of Zirconia Ceramic in various manufacturing applications, from aerospace components to medical devices. As businesses seek to optimize their processes and reduce production costs while maintaining high-quality standards, integrating Zirconia Ceramic innovations presents a promising avenue for achieving operational excellence and competitive advantages in the marketplace.

In the quest for manufacturing excellence, identifying key areas for improvement is crucial. One area that has seen significant advancements is the integration of zirconia ceramics. A study from the International Journal of Advanced Manufacturing Technology reports that the incorporation of zirconia can enhance wear resistance and reduce production downtime by up to 30%. This is particularly relevant in industries where durability and precision are paramount, such as aerospace and automotive manufacturing.

Another critical aspect revolves around process efficiency. According to a market analysis by Research and Markets, implementing advanced zirconia ceramic materials can lead to improved thermal stability and reduced energy consumption during manufacturing processes. The data indicates that manufacturers adopting these innovations have seen a reduction in cycle times by as much as 25%. By focusing on integrating zirconia ceramics into their processes, manufacturers can not only enhance product quality but also lower operational costs, making a compelling case for investing in these advanced materials.

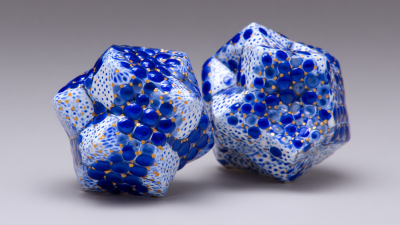

Zirconia ceramics have revolutionized the manufacturing industry by offering unique properties that enhance production processes. Exhibiting exceptional toughness and strength, zirconia ceramics are capable of withstanding high levels of stress and wear, making them ideal for various industrial applications. According to a recent report by the International Journal of Applied Ceramic Technology, zirconia ceramics possess a fracture toughness of up to 10 MPa·m^1/2, which significantly surpasses traditional ceramics. This durability not only extends the lifespan of components but also reduces maintenance costs, allowing manufacturers to allocate resources more efficiently.

In addition to their mechanical properties, zirconia ceramics demonstrate excellent thermal stability and chemical resistance. They can operate in extreme temperatures and harsh environments without degrading, which is crucial for sectors such as aerospace and automotive manufacturing. The Materials Science and Engineering Journal notes that zirconia ceramics maintain their integrity even at temperatures exceeding 1000°C, enabling manufacturers to optimize their processes and improve productivity. By harnessing these advantages, companies can enhance product quality and performance, ultimately leading to greater competitiveness in today’s market.

Integrating zirconia ceramics into existing production lines can significantly enhance manufacturing efficiency and product quality. Zirconia ceramics are renowned for their superior strength, wear resistance, and thermal stability. Recent industry reports indicate that the global zirconia ceramics market is projected to reach $7.5 billion by 2027, growing at a CAGR of 6.5% (Research and Markets, 2023). This growth reflects the increasing demand for advanced materials in sectors such as aerospace, automotive, and medical device manufacturing.

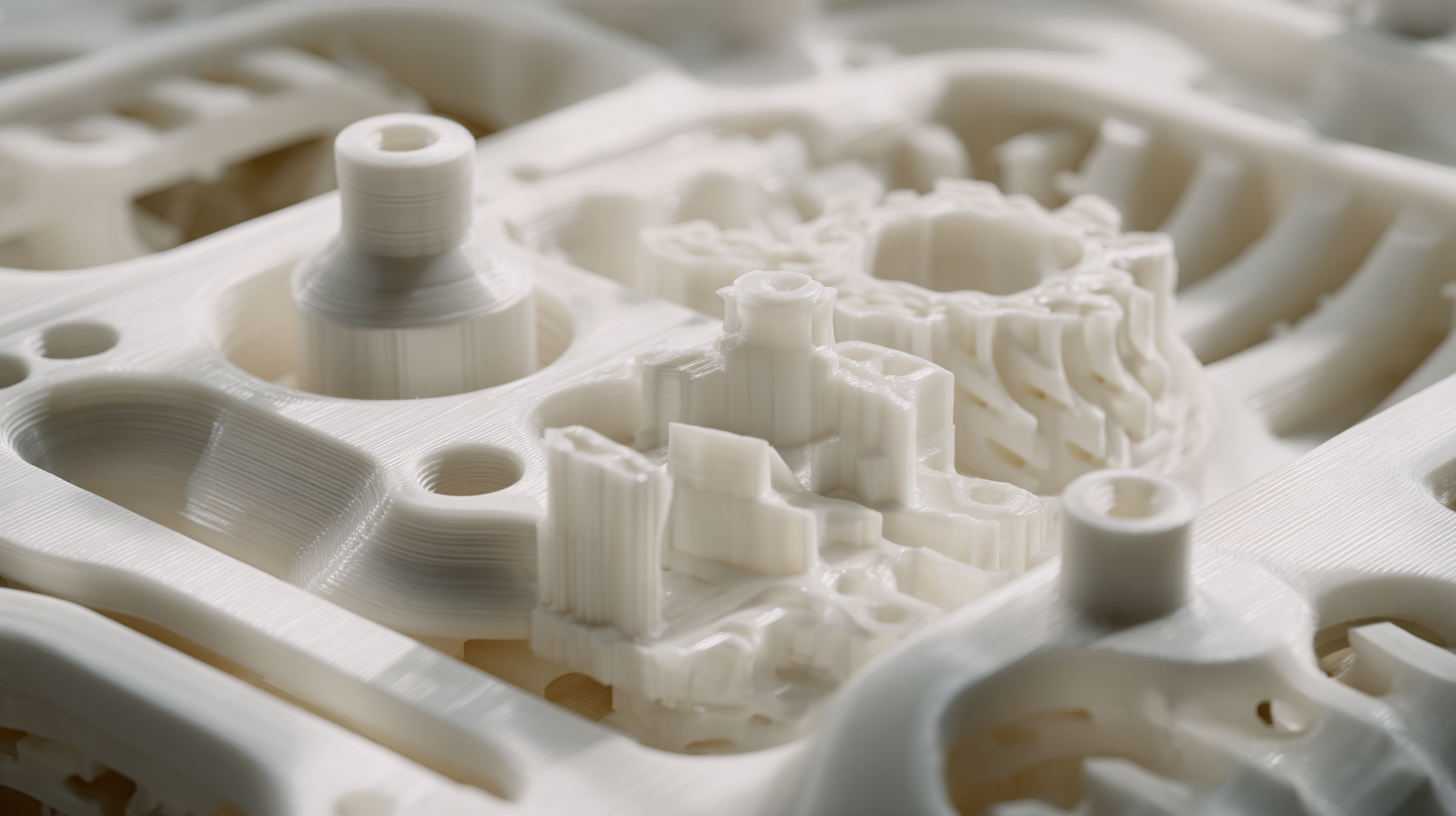

To seamlessly incorporate zirconia ceramics into your production process, consider the following tips: First, engage in thorough training of your staff to familiarize them with the properties and handling of zirconia materials. Having a clear understanding of the material's benefits can lead to innovative applications. Second, invest in equipment that is compatible with zirconia production, such as advanced sintering furnaces, to maximize efficiency. Lastly, establish a robust quality control framework, as maintaining consistent standards is crucial for leveraging the strengths of zirconia ceramics in your products.

As you explore integration strategies, analyze your current workflows to pinpoint areas where zirconia ceramics can create value. For example, replacing traditional materials with zirconia in high-wear applications can lead to reduced maintenance costs and extended product lifespans, ultimately enhancing your competitive edge in the market.

The evolving landscape of manufacturing processes has seen remarkable advancements with the introduction of zirconia ceramic innovations. A critical aspect to consider when implementing these materials is the cost-benefit analysis that evaluates their economic viability. Assessing the costs of zirconia innovations involves not only the initial investment in machinery and materials but also the long-term savings associated with durability and performance. Zirconia ceramics exhibit exceptional resistance to wear and thermal shock, leading to decreased maintenance costs and extended product lifespans, which can significantly enhance overall production efficiency.

Moreover, the integration of zirconia ceramics can improve energy efficiency in manufacturing workflows. Similar to the advancements in hydrogen production technologies that focus on optimizing energy outputs while minimizing emissions, zirconia materials can contribute to reducing waste and energy consumption in various manufacturing applications.

As manufacturers strive to transition to more sustainable practices, the potential for zirconia innovations to facilitate a low-carbon footprint while delivering substantial operational savings makes them a compelling choice in today's market. Each element of the cost-benefit analysis highlights these innovations' dual role in enhancing profitability and promoting environmental stewardship.

Implementing zirconia ceramic solutions in manufacturing processes can significantly enhance efficiency and product quality. However, to unlock the full potential of these innovations, comprehensive training and support are essential. Manufacturers must invest in educating their teams about the unique properties and applications of zirconia ceramics, as well as the best practices for their integration into existing workflows. This training should include both theoretical knowledge and hands-on experience, enabling workers to understand how to leverage zirconia's advantages, such as its exceptional toughness and resistance to wear.

Beyond initial training, ongoing support plays a critical role in sustaining productivity improvements. Establishing a feedback loop allows for continuous learning and adaptation, helping teams to troubleshoot challenges as they arise. Collaboration with zirconia ceramic suppliers can provide access to a wealth of resources, including troubleshooting manuals and iterative performance assessments. By fostering an environment of support and continuous improvement, manufacturers can ensure a smoother transition to zirconia ceramic technologies, ultimately driving long-term success in their operations.

This chart illustrates the efficiency improvements in various manufacturing processes after implementing zirconia ceramic solutions. The data reflects productivity levels across different areas, showcasing the benefits of innovation.