Leave Your Message

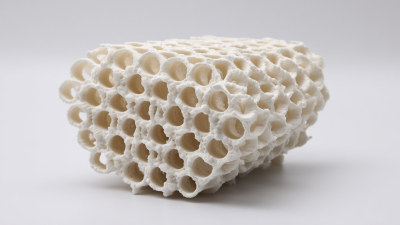

In recent years, the industrial landscape has witnessed transformative innovations that redefine standards across various sectors. One such breakthrough making waves is the introduction of Porous Alumina Ceramics. These advanced materials are gaining recognition for their unique properties, which combine lightweight design with exceptional mechanical strength and thermal stability. The versatility of Porous Alumina Ceramics not only enhances performance in demanding applications but also contributes to sustainability by reducing resource and energy consumption.

As industries strive for efficient solutions, this revolutionary material stands out by offering superior filtration, insulation, and structural benefits. In this blog, we will delve into seven compelling reasons why Porous Alumina Ceramics are not just an upgrade but a significant leap forward in industrial material standards, paving the way for smarter and more effective manufacturing processes.

Porous alumina ceramics have emerged as a game-changer in various industries, thanks to their unique properties that foster innovation and efficiency. One of the standout features of these materials is their exceptional permeability, which allows for the efficient flow of fluids and gases. This characteristic makes porous alumina ideal for applications in filtration systems and catalysis, where rapid and effective separation processes are crucial. Additionally, their high thermal resistance enables the ceramics to withstand extreme operating conditions, making them suitable for aerospace and automotive components where durability is paramount.

Another compelling property of porous alumina ceramics is their lightweight nature combined with impressive mechanical strength. This dual advantage helps reduce overall system weight while ensuring reliability and longevity. As a result, industries that require materials capable of enduring high stress while remaining light are increasingly turning to porous alumina. Furthermore, their biocompatibility opens new avenues in the medical field, particularly in bone regeneration and dental applications. This multifaceted functionality not only drives industrial innovation but also paves the way for sustainable and efficient solutions across various sectors.

Porous alumina ceramics are gaining traction across various industries due to their unique properties and versatility. In the medical field, these ceramics are commonly utilized in bone grafting and dental implants, owing to their biocompatibility and ability to promote osseointegration. Their porous structure allows for enhanced cell growth and nutrient absorption, making them ideal for applications that require long-term integration with biological systems.

In the realm of filtration and catalysis, porous alumina ceramics play a pivotal role. Their high surface area and excellent mechanical strength make them perfect for use in air and water purification systems. By effectively filtering out contaminants and particles, these ceramics contribute to cleaner environments and improved public health. Furthermore, their ability to act as a catalyst support enhances reactions in various chemical processes, streamlining production in the petrochemical and automotive industries. As these applications continue to expand, porous alumina ceramics are indeed setting new industry standards.

| Application Sector | Key Benefits | Performance Features | Market Growth Rate (%) |

|---|---|---|---|

| Biomedical | Biocompatibility, lightweight | High porosity, excellent mechanical strength | 15% |

| Environmental | Filtration efficiency, reduced environmental footprint | Chemical resistance, enhanced surface area | 12% |

| Aerospace | Heat resistance, weight reduction | Durability under high temperature | 10% |

| Automotive | Improved fuel efficiency, emissions reduction | Corrosion resistance, lightweight | 8% |

| Electronics | Thermal stability, increased longevity | Low thermal conductivity, excellent insulation | 20% |

Porous alumina ceramics are increasingly being recognized for their superior performance compared to traditional materials across various industries. A recent report by MarketsandMarkets predicts that the global market for advanced ceramics, including porous alumina, will reach USD 110 billion by 2026, growing at a CAGR of 6.8%. This growth is largely driven by their unique properties such as high porosity, low density, and excellent chemical stability, which make them suitable for applications in filtration, catalysis, and energy storage.

In contrast, traditional materials like metals and non-porous ceramics often fall short in specific use cases due to their density and weight, which can impede efficiency. For instance, porous alumina offers a 30-50% reduction in weight, enabling easier handling and installation. Furthermore, while traditional materials tend to face challenges with thermal shock resistance, porous alumina ceramics can withstand temperature fluctuations, boasting a thermal shock resistance of up to 450°C. As industries increasingly prioritize sustainability and efficiency, the adoption of porous alumina ceramics over conventional materials represents a significant shift in industry standards.

Porous alumina ceramics are quickly gaining recognition in various manufacturing processes, thanks to their unique properties that enhance efficiency and performance. One of the key advantages of using these ceramics is their exceptional thermal stability, allowing for operation in high-temperature environments without deforming or degrading. This makes them ideal for applications such as furnace linings, where maintaining structural integrity is critical. Additionally, their lightweight nature reduces transportation costs and eases handling during manufacturing.

Another significant benefit is their outstanding porosity, which enables superior filtration and separation capabilities. By allowing fluids to pass through while selectively trapping particles, porous alumina ceramics are increasingly utilized in water purification systems, catalysis, and even biomedical applications. Manufacturers are finding that incorporating these materials not only improves product quality but also increases sustainability by reducing waste.

Tips: When considering porous alumina ceramics for your next project, evaluate the specific porosity levels required for your application to maximize efficiency. Additionally, conduct thorough testing to understand how these ceramics interact with other materials in your process, ensuring optimal performance and durability. Collaboration with experienced suppliers can also provide valuable insights into the best practices for integrating these innovative materials into your manufacturing workflow.

The advancements in porous alumina ceramic technology are set to revolutionize industrial applications across various sectors. As industries increasingly prioritize efficiency and sustainability, developments in this unique material enable solutions that were previously deemed impossible. Innovative manufacturing techniques, such as 3D printing and advanced sintering processes, are enhancing the structural integrity and versatility of porous alumina ceramics, making them suitable for both high-temperature environments and lightweight applications.

When considering the implementation of porous alumina ceramics, it’s essential to evaluate their thermal and mechanical properties to ensure optimal performance. Tip: Collaborate with material scientists to explore custom formulations that can meet specific industry requirements, such as improved wear resistance or enhanced thermal conductivity. As these materials continue to evolve, one can also anticipate a growing trend towards bio-inspired designs that mimic natural systems, leading to even more efficient and effective applications.

Moreover, the scaling up of production methods indicates a shift towards more sustainable practices in manufacturing. Tip: Invest in technologies that allow for the recycling and reusability of ceramic materials, which not only reduces waste but also aligns with global sustainability goals. As porous alumina ceramics gain traction, staying attuned to these emerging trends will be vital for businesses looking to maintain a competitive edge in their respective fields.