Leave Your Message

In the realm of high-temperature applications, the significance of Refractory Sagger cannot be overstated. Refractory saggers are specialized ceramic containers used to support and protect materials during the firing process of ceramics and glass at elevated temperatures that can exceed 1400°C. According to a report by the Global Refractories Market Analysis, the demand for high-performance refractories, which includes saggers, is projected to grow substantially, driven by the increasing need for energy-efficient and sustainable practices across industries such as ceramics, glass, and metal production.

The unique properties of Refractory Saggers, including their resistance to thermal shock and chemical corrosion, make them indispensable in ensuring quality and precision in high-temperature firing processes. Industry statistics indicate that the global refractory market is expected to reach $27 billion by 2026, with a significant portion attributed to the growing adoption of advanced refractory materials capable of withstanding extreme conditions. This surge reflects not only the necessity for durable materials in manufacturing but also the ongoing innovations aimed at enhancing the thermal performance and lifespan of refractory solutions.

In summary, as industries continue to evolve towards more demanding high-temperature applications, the role of Refractory Saggers becomes increasingly critical. Their ability to facilitate efficient heat management and material integrity under extreme conditions positions them as essential components in modern manufacturing processes.

Refractory saggers play a crucial role in high-temperature processes where maintaining structural integrity is essential. These components are designed to withstand extreme thermal conditions, often exceeding 1,400 degrees Celsius. In industries such as ceramics and metal processing, refractory saggers provide a stable support system for materials being fired or melted, ensuring that they maintain their shape and properties under intense heat. The ability of these saggers to endure prolonged exposure to high temperatures without sagging or deforming is vital for achieving the desired quality in finished products.

Moreover, the use of refractory saggers helps in optimizing energy efficiency in high-temperature applications. By providing a robust platform for materials, saggers minimize thermal losses and enhance heat retention during processes like kiln firing. This leads to more consistent results and reduced energy consumption, ultimately contributing to more sustainable manufacturing practices. In addition to energy efficiency, refractory saggers also protect against contamination during the processes, ensuring that the materials being processed retain their purity and functional characteristics. Thus, their importance in high-temperature applications cannot be overstated, as they are integral to both performance and product quality.

Refractory saggers play a crucial role in high-temperature applications, particularly in industries such as ceramics and glass manufacturing. These components act as carriers for products during firing processes, ensuring that materials are thoroughly and uniformly heated. Their material properties are specifically engineered to withstand extreme conditions, including temperatures exceeding 1400°C (2550°F). According to industry reports, the thermal stability, low thermal conductivity, and high resistance to thermal shock are vital characteristics that make refractory saggers indispensable.

The composition of refractory saggers typically includes alumina, silica, and other ceramic materials that enhance their durability and performance. Research indicates that saggers with a high alumina content can withstand higher temperatures and exhibit better mechanical strength, making them suitable for demanding industrial environments. In addition to thermal performance, the chemical stability of these materials ensures that they do not react negatively with the products they support, maintaining the integrity and quality of the final output.

Tips: When selecting refractory saggers, consider the specific temperature and chemical conditions of your application. Always refer to industry guidelines to choose materials with the appropriate properties that align with your operational requirements. Regular maintenance and inspection of saggers can also extend their lifespan and ensure consistent performance in high-temperature processes.

Refractory saggers play a crucial role in various industrial applications, particularly in sectors that require high-temperature processing. These robust materials are designed to withstand extreme thermal conditions, making them indispensable in ceramics, metal casting, and glass manufacturing. In the ceramic industry, saggers are used to hold ceramic pieces during firing, preventing deformation and ensuring uniform heat distribution. This capability is essential for producing high-quality finished products that meet stringent specifications.

In addition to ceramics, refractory saggers are extensively employed in metal casting. They serve as protective containers for molten metal, helping to maintain temperature while preventing contamination. This application not only enhances the quality of cast products but also improves the efficiency of the casting process. Furthermore, in glass production, saggers support glass items during high-temperature processes, aiding in their proper shape and minimizing defects. The versatility of refractory saggers thus makes them a vital component across multiple high-temperature industrial settings, contributing to both the reliability and quality of end products.

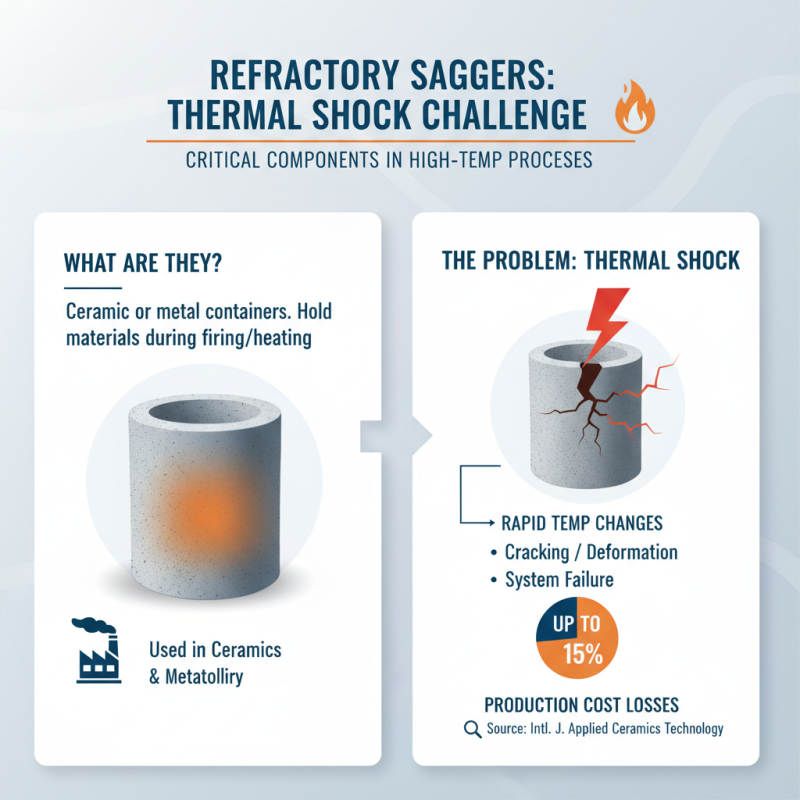

Refractory saggers are critical components in various high-temperature industrial processes, particularly in sectors like ceramics and metallurgy. However, they face significant challenges due to the extreme conditions they must endure. One of the primary issues is thermal shock, which occurs when a refractory sagger experiences rapid temperature fluctuations. This can lead to cracking or deformation, severely impacting the integrity and performance of the entire system. According to a report by the International Journal of Applied Ceramics Technology, losses from thermal shock in refractory materials can account for up to 15% of overall production costs in high-temperature facilities.

Another challenge lies in material degradation over time. Prolonged exposure to high temperatures can lead to chemical reactions between the sagger materials and the payload, resulting in wear and reduced lifespan. A study published by the Refractory Industry Association indicates that the lifespan of refractory saggers in continuous production environments can decrease dramatically, with an average operational life of only 5-10 years under optimal conditions. This not only necessitates regular replacement and maintenance but also requires ongoing research into more resilient materials that can withstand these harsh conditions without compromising performance. As industries continue to push the boundaries of temperature and efficiency, the importance of developing advanced refractory saggers becomes increasingly paramount.

The advancement of refractory sagger technology is set to revolutionize high-temperature applications across various industries. With evolving material science, researchers are focusing on enhancing the thermal stability, durability, and resistance of refractory saggers. Innovations such as incorporating advanced ceramics and composites are expected to significantly improve the performance of these critical components. This will not only extend their life expectancy but also optimize the overall efficiency of high-temperature processes in sectors like ceramics, glass, and metallurgy.

Future developments may also include the integration of smart technologies within refractory saggers. By embedding sensors that monitor temperature and stress conditions, manufacturers can achieve real-time data on the saggers' performance. This continuous feedback loop will enable predictive maintenance and minimize downtime, thereby enhancing productivity. Furthermore, advances in computer modeling and simulation techniques can streamline the design and testing phases, allowing for custom solutions that meet specific operational demands while pushing the boundaries of what is achievable in high-temperature environments.