Leave Your Message

In the rapidly evolving landscape of advanced materials, Porous Alumina Ceramics have emerged as a pivotal solution across various industries, including filtration, catalysis, and biomaterials. According to a recent market analysis by Grand View Research, the global alumina ceramics market is projected to reach USD 9.84 billion by 2025, with a significant demand for porous variations supporting efficient fluid transport and enhanced strength.

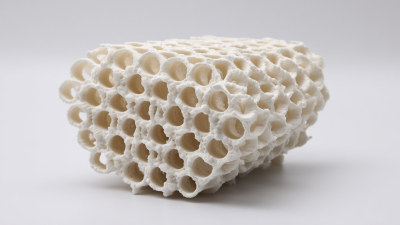

The unique properties of Porous Alumina Ceramics, such as high thermal resistance and superior mechanical stability, make them ideal candidates for applications that require lightweight yet durable materials.

As industries strive for sustainability, understanding how to select the best Porous Alumina Ceramics tailored to specific needs becomes crucial for achieving competitive advantages.

This guide will navigate the critical factors manufacturers and engineers should consider when choosing these advanced materials for optimal performance in their applications.

In the rapidly evolving landscape of advanced materials, Porous Alumina Ceramics have emerged as a pivotal solution across various industries, including filtration, catalysis, and biomaterials. According to a recent market analysis by Grand View Research, the global alumina ceramics market is projected to reach USD 9.84 billion by 2025, with a significant demand for porous variations supporting efficient fluid transport and enhanced strength.

The unique properties of Porous Alumina Ceramics, such as high thermal resistance and superior mechanical stability, make them ideal candidates for applications that require lightweight yet durable materials.

As industries strive for sustainability, understanding how to select the best Porous Alumina Ceramics tailored to specific needs becomes crucial for achieving competitive advantages.

This guide will navigate the critical factors manufacturers and engineers should consider when choosing these advanced materials for optimal performance in their applications.

When considering the selection of porous alumina ceramics, it is essential to understand the different types available and their specific applications across various industries. Porous alumina ceramics are categorized primarily based on their pore structure and composition, influencing their mechanical strength, thermal stability, and permeability.

For instance, traditional high-density alumina ceramics are often employed in applications requiring excellent mechanical properties and wear resistance. According to a report by Freedonia Group, the global demand for alumina ceramics is projected to reach $18.5 billion by 2025, with substantial growth driven by the aerospace and automotive sectors.

On the other hand, low-density porous alumina ceramics, which have higher porosity, are particularly advantageous in filtration applications due to their enhanced surface area and lighter weight. The increasing focus on environmental sustainability is boosting the demand for such materials, especially in water purification systems. A recent study highlighted in the "Journal of Materials Science" indicates that these porous structures can significantly improve filtration efficiency, making them ideal for industries such as environmental engineering and biomedical applications, where performance and reliability are paramount. Understanding these distinctions allows industries to select the most appropriate alumina ceramic types tailored to their specific operational requirements.

When selecting porous alumina ceramics for your industry needs, several key factors come into play. The primary consideration should be the specific application for which the ceramics will be used. Different industries, such as filtration, insulation, or catalyst support, have distinct requirements regarding pore size, permeability, and mechanical strength. Understanding these parameters will ensure that you choose a product that meets your operational demands.

Another important factor to consider is the manufacturing process of the ceramics. The method used to create porous alumina can significantly affect its properties. For example, techniques like sol-gel processing or the use of foam templates can result in varying degrees of porosity and structural integrity. Before making a decision, it's essential to evaluate the production methods and how they align with your performance needs.

Tips: When assessing potential suppliers, always request samples to test the material in your specific application. Additionally, consider the supplier's reputation for quality control and consistency. Engaging with a supplier that offers technical support and insights into the behavior of their products under various conditions can also greatly benefit your selection process.

When selecting porous alumina ceramics for your industrial applications, it's essential to consider the unique requirements of various sectors, as each industry applies distinct performance metrics. For instance, in the healthcare industry, biocompatibility and sterility are paramount, making ceramics with controlled pore size and high purity critical. These materials facilitate cell growth and are often used in implants or filtration systems. Conversely, the energy sector may prioritize thermal stability and resistance to aggressive chemicals, necessitating a focus on ceramics with superior structural integrity under high stress.

Additionally, industries such as automotive manufacturing benefit from alumina ceramics due to their lightweight yet durable properties, which contribute to enhanced fuel efficiency and performance. In this context, the choice of pore structure can also influence heat dissipation and noise vibration damping. Therefore, a comparative analysis of the varying compositions and manufacturing processes of porous alumina can provide insights into which type best suits each industry's specific demands, ensuring optimal performance and longevity of the materials employed.

| Industry | Porosity (%) | Mean Pore Diameter (µm) | Mechanical Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Application |

|---|---|---|---|---|---|

| Biomedical | 50 | 3.5 | 25 | 10 | Bone scaffolds |

| Filtration | 40 | 2.8 | 30 | 15 | Water purification |

| Catalysis | 35 | 1.5 | 45 | 20 | Chemical reactions |

| Electronics | 25 | 1.0 | 60 | 25 | Substrates |

| Construction | 30 | 2.0 | 35 | 30 | Insulation materials |

When selecting porous alumina ceramics for specific industrial applications, it is crucial to evaluate their performance through rigorous testing and quality assurance processes. These ceramic materials must exhibit characteristics such as appropriate porosity, strength, and thermal stability to meet the demands of diverse environments. A systematic approach to testing can help identify the most suitable products for your needs.

One essential tip is to conduct permeability tests to assess how well the alumina ceramics allow fluids to pass through. This characteristic is vital for applications in filtration and catalysis. Additionally, implementing mechanical strength tests ensures that the ceramics can withstand the operational stresses they will encounter. Regular inspection and compliance with industry standards can further assure quality.

Another important aspect is thermal testing. Porous alumina should maintain stability under varying temperature conditions, which is critical for processes involving heat. Consider using advanced techniques like thermal shock tests to evaluate performance under rapid temperature changes. These methods not only enhance the quality assurance process but also provide confidence in the longevity and reliability of the ceramics in your industry applications.

When selecting porous alumina ceramics for industrial applications, it is essential to balance cost and benefit to make an informed decision. The initial investment in high-quality materials can be significant, but the long-term advantages often justify the expense. Porous alumina ceramics are renowned for their durability, thermal stability, and excellent filtration properties, making them ideal for various applications, from environmental technology to biomedical engineering. By analyzing the specific requirements of your industry, you can determine which features will deliver the most value and ensure these ceramics meet your operational demands.

Furthermore, consider the life cycle costs associated with porous alumina ceramics. While cheaper alternatives may save money upfront, they can lead to increased maintenance and replacement costs over time. Assessing parameters such as permeability, mechanical strength, and resistance to thermal shock will help you identify the ceramic that strikes the right balance between cost and performance. Ultimately, investing in the right porous alumina ceramics will enhance productivity and efficiency in your operations, leading to greater overall savings and success in your industry.