Leave Your Message

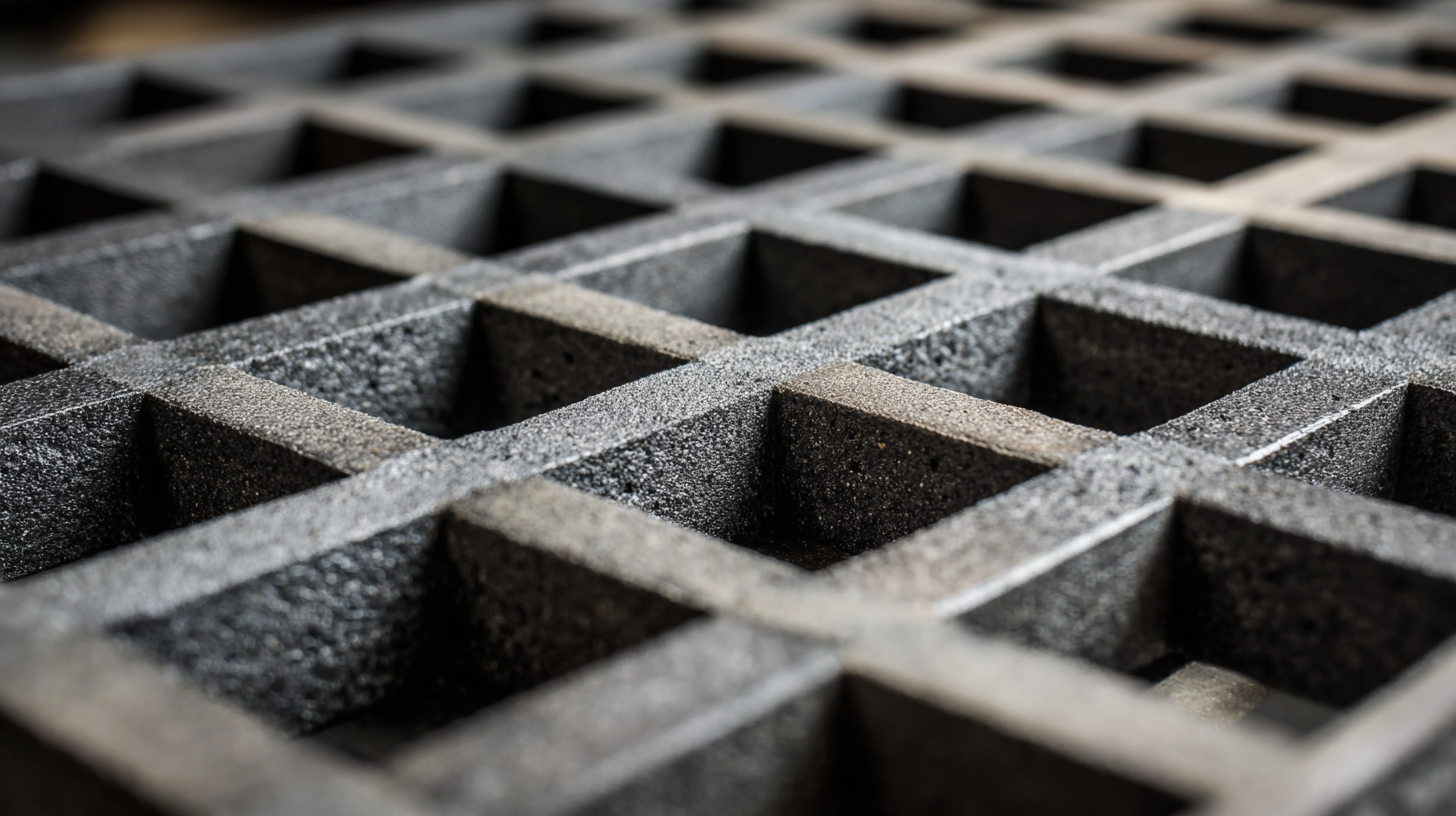

In the realm of modern ceramic practices, the advent of Silicon Carbide Kiln Shelves has revolutionized the firing process and overall efficiency of ceramic production. Known for their exceptional thermal conductivity, durability, and resistance to warping, these innovative kiln shelves play a crucial role in achieving optimal results in temperature control and firings.

As artisans and manufacturers search for ways to enhance their workflow and products, Silicon Carbide Kiln Shelves provide a robust solution that not only maximizes output but also minimizes energy consumption.

As artisans and manufacturers search for ways to enhance their workflow and products, Silicon Carbide Kiln Shelves provide a robust solution that not only maximizes output but also minimizes energy consumption.

This introduction will explore the myriad of benefits brought forth by these shelves, showcasing how they facilitate various techniques and encourage creative exploration in ceramic artistry. Ultimately, embracing Silicon Carbide Kiln Shelves represents a significant step forward for both traditional and contemporary ceramicists seeking to push the boundaries of their craft.

Silicon carbide kiln shelves have emerged as a game-changer in modern ceramic firing practices, offering numerous advantages that enhance both efficiency and product quality. According to a report by the American Ceramic Society, the thermal conductivity of silicon carbide is significantly higher than traditional materials, which allows for more uniform heat distribution throughout the kiln. This uniformity minimizes thermal stress on the ware during firing, reducing the risk of cracks and warping. Moreover, the ability of silicon carbide to withstand high temperatures—up to 1,600°C—makes it particularly suitable for high-fire ceramics, which are increasingly popular among contemporary artists and manufacturers.

Another compelling advantage is the longevity of silicon carbide kiln shelves. Research indicates that these shelves have a lifespan that is three to five times longer than conventional shelves made of clay or other materials. This durability not only translates into cost savings over time but also lessens the need for frequent replacements, thereby reducing waste in ceramic facilities. Additionally, silicon carbide’s resistance to chemical attack means that it can withstand corrosive glazes without deteriorating, maintaining a smoother surface for subsequent firings and enhancing the overall quality of the finished pieces. As this innovative material continues to gain traction, its role in elevating modern ceramic practices cannot be understated.

Silicon carbide kiln shelves have become increasingly popular in modern ceramic practices, particularly for their ability to enhance glaze finishes. One creative strategy is utilizing these shelves to achieve a uniform heat distribution within the kiln. The high thermal conductivity of silicon carbide allows for even firing, which helps to prevent uneven glaze application and promotes a smoother finish. Artists can also experiment with different placements of their pieces on the shelves to manipulate heat exposure, fostering unique glaze effects that can redefine their work.

Another innovative approach involves using silicon carbide shelves in conjunction with various kiln atmospheres. By carefully controlling the atmosphere—oxidation or reduction—ceramists can influence the chemical reactions that occur during firing, enhancing specific glaze characteristics. The ability to experiment with these variables opens up new avenues for artistic expression. Additionally, the durability and strength of silicon carbide mean that artists can push their work further, capable of withstanding the rigors of high-temperature firing while delivering exceptional results. The intersection of material science and creativity in this context exemplifies how silicon carbide kiln shelves can revolutionize traditional ceramic practices.

| Application | Technique | Benefit | Example Glaze |

|---|---|---|---|

| High-Temperature Firing | Use of silicon carbide shelves to withstand extreme temperatures | Improved durability and longevity | Raku Glaze |

| Even Heat Distribution | Layered placement of kiln shelves | Consistent glazing results | Satin Matte Glaze |

| Textured Effects | Using textured silicon carbide shelves for imprinting | Unique surface designs | Crystalline Glaze |

| Reduced Warping | Support heavy pieces evenly | Maintaining form and integrity | Translucent Glaze |

| Efficient Firing Cycle | Utilization of heat retention properties | Energy savings and faster cycles | Ash Glaze |

When it comes to maintaining optimal temperature in ceramics, the use of silicon carbide kiln shelves presents several advantages over traditional shelves. Silicon carbide is renowned for its ability to withstand extreme thermal environments, which allows ceramic artists to fire their work at higher temperatures and more efficiently than traditional materials. As temperatures rise within the kiln, these shelves maintain consistent thermal stability, reducing the risk of warping and ensuring even heat distribution essential for achieving perfect results in ceramic firing.

In addition to their thermal qualities, handling silicon carbide shelves also requires careful attention to temperature management. Just as pharmaceutical manufacturers rely on temperature-controlled environments to preserve product integrity, ceramicists can benefit from implementing similar guidelines. It's crucial to monitor kiln conditions and avoid sudden temperature changes that could lead to thermal shock. Embracing these practices not only preserves the integrity of the ceramic products but also maximizes the life and function of the silicon carbide shelves themselves, making them a valuable asset in modern ceramic practices.

In modern ceramic practices, innovative shelf arrangements using silicon carbide kiln shelves are revolutionizing the way artisans approach firing processes. Much like the clever storage solutions recently highlighted for maximizing space in small areas, these kiln shelves allow for efficient stacking and organization, optimizing the use of kiln space to achieve consistent firing results. According to industry reports, utilizing strategically arranged kiln shelves can enhance airflow and heat distribution, leading to improved product quality and reduced firing times—critical factors in today's competitive ceramic market.

Furthermore, the integration of new technologies in kiln operations mirrors advancements seen in other sectors, such as retail and biotech. For instance, innovative startups are harnessing smart shelf technologies to enhance product visibility and consumer engagement. Similarly, ceramic practitioners can benefit from adopting data-driven strategies for shelf arrangement that leverage analytics on heat distribution and material behavior, ultimately boosting their productivity and output. As efficiency becomes increasingly paramount in all industries, the ceramic field stands to gain significantly from these innovative approaches to kiln shelf utilization.

Investing in silicon carbide kiln shelves can yield significant long-term benefits for modern ceramic practices. These shelves offer exceptional durability and thermal stability, making them a smart choice for professional studios and hobbyists alike. Although the initial cost may be higher than traditional shelves, their longevity and resistance to warping ultimately result in savings on replacement costs and maintenance. Moreover, silicon carbide shelves are known to enhance even heat distribution during firing, which can lead to improved final product quality, further complementing their value.

Tips: When considering the transition to silicon carbide kiln shelves, assess the specific needs of your studio or workspace. Evaluate the frequency of use and firing temperatures to determine the appropriate shelf thickness and configuration that will maximize your investment. Additionally, keep in mind that combining these shelves with proper care and maintenance practices will extend their operational life, ensuring you reap the benefits for years to come.

Ultimately, the cost-benefit analysis of investing in silicon carbide kiln shelves leans heavily towards long-term gains and improved firing results. By carefully analyzing your studio's requirements and understanding the advantages of these innovative shelves, you can make informed decisions that will elevate your ceramic work.