Leave Your Message

In the ever-evolving ceramics industry, optimizing production efficiency is crucial for meeting the increasing demands for high-performance materials such as Cordierite Mullite Sagger. According to a recent report by MarketsandMarkets, the global market for advanced ceramics is expected to reach $137.4 billion by 2026, driven largely by the growing need for innovative solutions in kiln furniture and other applications. As manufacturers seek to enhance their production processes, adopting top strategies in the creation of Cordierite Mullite Saggers can significantly reduce costs and improve product quality. By implementing data-driven methodologies and advanced manufacturing techniques, plants can achieve remarkable gains in efficiency, ensuring that they remain competitive in a rapidly changing market landscape. This blog will explore actionable tips and innovative practices that can lead to substantial advancements in Cordierite Mullite Sagger production, enabling manufacturers to navigate industry challenges with confidence.

Optimizing raw material selection is critical for enhancing the efficiency of cordierite mullite sagger manufacturing. The qualities of the raw materials directly influence the final product's strength, thermal stability, and overall performance in high-temperature applications. Manufacturers should prioritize sourcing high-purity aluminum oxide and silica, as impurities can lead to defects and compromise the structural integrity of the saggers. Additionally, evaluating the particle size and distribution of raw materials can facilitate better mixing and improve the uniformity of the final product, reducing the likelihood of weak spots.

Another crucial aspect of raw material selection is sustainability. By choosing eco-friendly materials and suppliers committed to sustainable practices, manufacturers not only reduce their environmental footprint but also enhance their marketability. Implementing a rigorous quality control system to assess raw materials before usage is also essential. Regular testing and analysis can ensure raw materials meet the required specifications, thereby minimizing production inconsistencies and enhancing overall efficiency in the sagger production process. By focusing on these best practices, manufacturers can significantly boost their production capabilities while maintaining high standards of quality and sustainability.

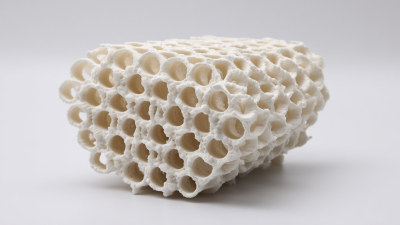

In the production of cordierite mullite saggers, thermal shock resistance is a critical factor that directly impacts both performance and longevity. The material composition plays a vital role in determining this property. The ideal formulation should balance alumina, silica, and magnesia components to ensure optimal thermal stability. The microstructure of the sagger, which can be enhanced through controlled firing processes, also significantly influences its ability to withstand rapid temperature changes. By focusing on these compositional and structural aspects, manufacturers can create saggers that excel under demanding thermal conditions.

Additionally, the firing conditions during production are paramount. A carefully controlled firing atmosphere can minimize defects and enhance the thermal shock resistance of cordierite mullite saggers. Implementing precise temperature profiles and cooling rates during the firing cycle ensures a uniform microstructure, which is essential for maximizing durability. Moreover, the inclusion of additives can further improve the thermal shock characteristics, enabling saggers to perform reliably in various high-temperature applications. These strategies, centered on addressing thermal shock resistance, are crucial for advancing production efficiency and ensuring the long-term success of cordierite mullite sagger manufacturing.

Innovative techniques to streamline the firing process of cordierite mullite saggers are crucial in enhancing production efficiency and reducing energy consumption. Recent industry reports indicate that optimizing the firing cycle can lead to a significant reduction in fuel usage, with data suggesting savings of up to 30% in energy costs. This can be achieved by implementing advanced kiln technologies such as variable frequency drives and enhanced insulation materials, which help maintain optimal temperature profiles throughout the firing process.

Moreover, incorporating real-time monitoring systems plays a vital role in achieving these efficiencies. By utilizing sensors and automation, manufacturers can achieve precise control over temperature and atmosphere, significantly minimizing defects in the final product. Studies have shown that adopting such smart technologies can lead to a 15% increase in the consistency of the saggers produced. As the industry increasingly focuses on sustainability and cost-effectiveness, these innovative approaches not only improve production metrics but also enhance the overall quality and longevity of cordierite mullite saggers.

| Strategy | Description | Expected Outcomes | Implementation Timeframe |

|---|---|---|---|

| Process Optimization | Enhancing firing schedules and temperatures to maximize energy efficiency. | Reduced firing costs and improved product uniformity. | 3-6 months |

| Material Selection | Using higher purity raw materials to enhance final product strength. | Increased product lifespan and reduced defect rates. | 2-4 months |

| Automation | Implementing automated systems for material handling and firing processes. | Increased throughput and reduced labor costs. | 6-12 months |

| Quality Control Enhancements | Implementing advanced monitoring techniques during production. | Improved consistency and reliability of the final products. | 4-8 months |

| Training Programs | Developing targeted training for staff on new equipment and processes. | Enhanced employee skills leading to better production outcomes. | 1-3 months |

In the realm of ceramic manufacturing, achieving high production efficiency while maintaining impeccable quality is paramount. The introduction of advanced technology in the production processes of cordierite mullite saggers has revolutionized the way quality control is implemented.

Automated monitoring systems equipped with real-time data analytics enable manufacturers to oversee every stage of the sagger production, allowing for immediate adjustments and interventions when needed. This proactive approach not only minimizes defects but also enhances overall throughput.

Automated monitoring systems equipped with real-time data analytics enable manufacturers to oversee every stage of the sagger production, allowing for immediate adjustments and interventions when needed. This proactive approach not only minimizes defects but also enhances overall throughput.

Moreover, leveraging cutting-edge technologies such as artificial intelligence and machine learning can significantly optimize quality control. By analyzing historical data, these systems can predict potential failures and suggest preventive measures, ensuring that each batch of saggers meets stringent quality standards. Additionally, incorporating IoT devices within the production line fosters a seamless flow of information, enabling manufacturers to identify bottlenecks and address inefficiencies without delay.

Embracing these innovations empowers manufacturers to enhance both the efficiency of their production processes and the quality of the end product.

The demand for cordierite mullite products is expected to experience significant growth in 2024, driven by various market trends that reflect the evolving needs of industries relying on advanced ceramics. With its unique properties, cordierite mullite is poised to find increased application in sectors such as automotive, aerospace, and electronics, where high thermal stability and low thermal expansion are critical. As manufacturers enhance their production efficiencies, they can better meet the anticipated rise in demand, positioning themselves favorably against competitors.

Analyzing the broader market context, industries are witnessing substantial growth rates across various segments, indicative of a trend towards more resilient and higher-quality materials. The compound annual growth rates (CAGR) for markets related to cordierite mullite, such as lightweight ceramics and advanced manufacturing techniques, suggest that there is a strong push for innovation within the sector. Companies that can adapt to these trends by advancing their production strategies and improving product offerings will likely capitalize on the increasing consumer and industrial demand for cordierite mullite solutions in the coming years.