Leave Your Message

As we navigate the dynamic landscape of 2025, technological advancements are reshaping various industries, with technical ceramics leading the charge in innovation and application. According to a report by MarketsandMarkets, the global technical ceramics market is projected to reach USD 11.71 billion by 2025, growing at a CAGR of 5.9%. This burgeoning sector is not only pivotal in electronics, aerospace, and healthcare but is also witnessing the emergence of innovative alternatives that enhance performance and sustainability. As businesses and researchers explore these new horizons, it becomes crucial to understand the impact and application of advanced technical ceramics in meeting the challenges posed by contemporary demands.

This blog will delve into the cutting-edge developments in technical ceramics, highlighting their transformative potential and the best practices for leveraging their benefits in various industries.

As we look toward 2025, the landscape of technical ceramics is set to undergo remarkable transformations, driven by innovative trends that prioritize sustainability and performance. According to a report by Research and Markets, the global technical ceramics market is expected to reach approximately $80 billion by 2025, growing at a CAGR of 6.4%. This growth is attributed to the increasing demand from key industries such as electronics, aerospace, and healthcare, where advanced materials are crucial for enhancing product efficiency and longevity.

One prominent trend is the integration of eco-friendly materials and manufacturing processes. With a pressing need for sustainable practices, many companies are exploring alternatives such as bio-based ceramics and recyclable composites. Research from Gartner indicates that organizations implementing sustainable materials can increase their market value by up to 15%.

**Tips: Ensure you stay ahead of the curve by investing in R&D focused on renewable resources, and consider collaborations with universities for innovative breakthroughs. Additionally, monitor customer feedback to adapt your product offerings to meet evolving demands.** Another noteworthy advancement is the rise of smart ceramics that incorporate sensors and conductive properties, opening new applications in smart manufacturing and IoT devices. These innovations not only elevate performance but also cater to a tech-savvy consumer base increasingly conscious of both functionality and environmental impact.

As the global demand for technical ceramics continues to rise, understanding the key import and export certifications becomes crucial for manufacturers and distributors. According to a recent report by MarketsandMarkets, the technical ceramics market is projected to reach USD 48.9 billion by 2025, growing at a CAGR of 7.1%. This surge is largely due to the material's applications in industries such as aerospace, automotive, and electronics, where high-performance materials are essential. For companies looking to trade in these specialized ceramics, obtaining the right certifications can significantly impact their ability to enter new markets and ensure product compliance.

Certification for technical ceramics typically includes ISO 9001 for quality management systems and ISO 14001 for environmental management. Additionally, certain products may require specific certifications such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, which addresses the safety of chemical substances. The compliance with these certifications not only helps in leveraging international trade but also assures clients of product reliability and safety. As the technical ceramics sector evolves, staying abreast of these regulatory requirements is vital for successful global operations.

In the rapidly evolving global ceramics market, compliance with international standards has become a crucial aspect for manufacturers and end-users alike. As technological advances in technical ceramics continue to emerge, companies must navigate a complex landscape of regulatory requirements. These standards not only ensure product safety and performance but also contribute to environmental sustainability by guiding production processes. Staying abreast of these regulations is essential for businesses aiming to maintain their competitive edge while adhering to quality benchmarks.

Moreover, innovative alternatives in technical ceramics are reshaping the marketplace, prompting a shift in compliance norms. New materials and manufacturing techniques, such as additive manufacturing and advanced sintering methods, require updated regulatory frameworks that address both performance and environmental impacts. As ceramic manufacturers explore these innovations, they must be proactive in engaging with compliance authorities to ensure their products meet evolving standards. This dialogue between technology and regulation will play a pivotal role in shaping the future of the ceramics industry, fostering both innovation and responsible production practices.

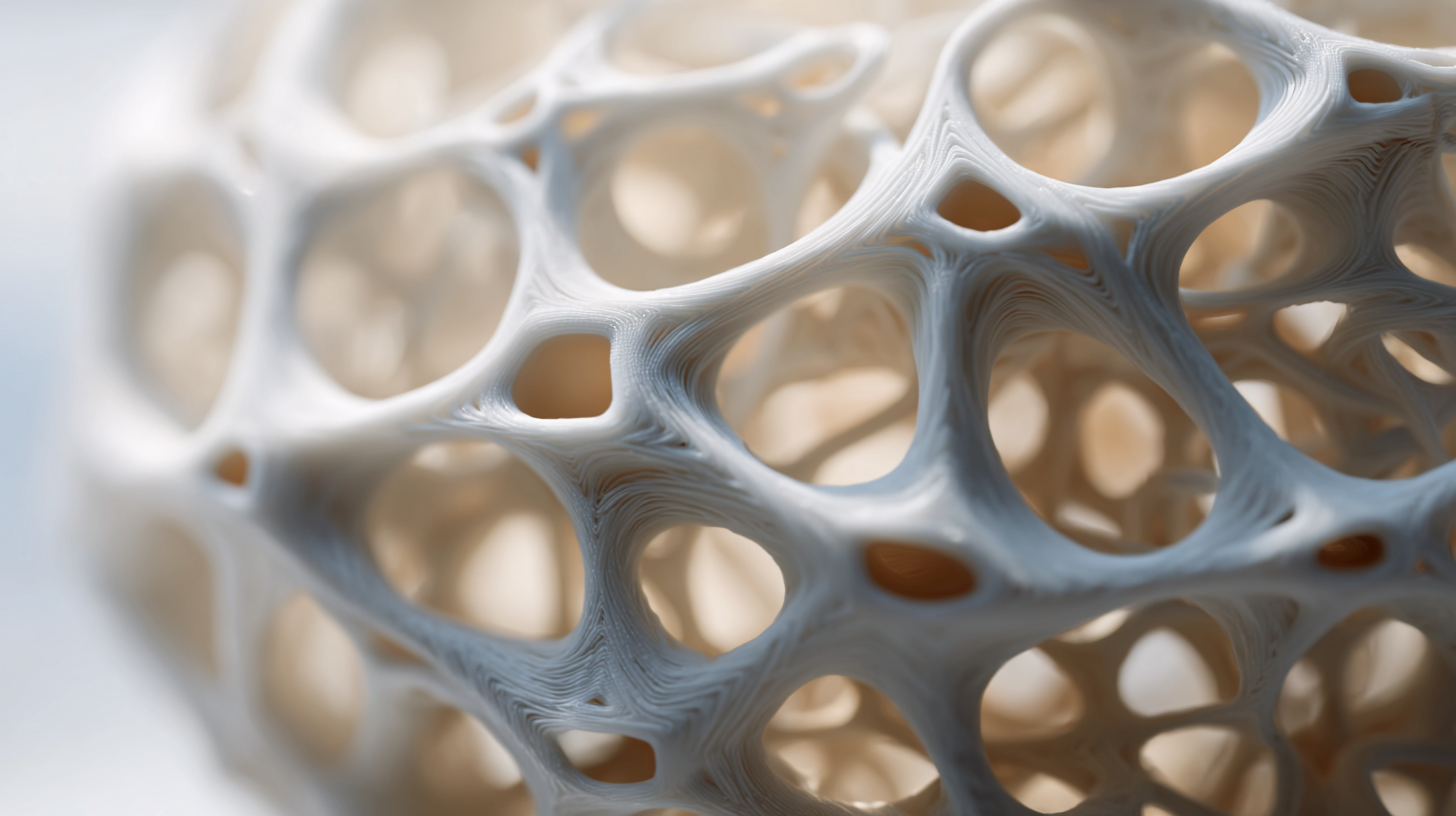

The future of ceramics is being reshaped by a wave of emerging technologies that promise to enhance their properties and expand their applications. One of the most exciting advancements is the use of additive manufacturing, or 3D printing, which allows for intricate designs and tailored properties that are difficult to achieve with traditional methods. This process not only reduces material waste but also enables the creation of complex structures that can significantly improve performance in various fields, from aerospace to medical devices.

Additionally, advancements in nanotechnology are revolutionizing the way ceramics are formulated. By manipulating materials at the molecular level, scientists can create ceramics with superior strength, thermal resistance, and electrical conductivity. These innovations pave the way for the development of next-generation ceramics suitable for high-performance applications in electronics, energy storage, and even wear-resistant coatings. As these technologies continue to evolve, they will undoubtedly open new avenues for research and industry, transforming our understanding and utilization of ceramics in the years to come.

When selecting the appropriate technical ceramics for specific applications, it's vital to consider the unique properties of advanced ceramics. Recent advancements in materials, such as high-purity magnesium oxide, highlight how specific characteristics—like a high melting point and excellent insulating capability—can meet demanding application requirements. For instance, in sectors such as aerospace and electronics, ceramics must demonstrate reliability under extreme conditions, which is where the precise composition and processing of advanced ceramics come into play.

Moreover, the engineering ceramic market is evolving, driven by innovative manufacturing techniques such as 3D printing. Although some may perceive a slowdown in the 3D printing sector, its integration into advanced ceramics is enhancing product complexity and functionality. Applications are expanding rapidly, from biomedical devices to cutting tools, which necessitates an informed approach when choosing ceramics. The right material selection not only impacts performance but also shapes future technological advancements, reinforcing the importance of thorough research and application understanding in this dynamic field.