Leave Your Message

In an era of rapid technological advancement, Zirconia Ceramic has emerged as a pivotal material redefining modern industries. Its unique combination of strength, durability, and versatility has led to groundbreaking innovations that are set to transform various sectors, from healthcare to manufacturing. The adaptability of Zirconia Ceramic allows for its integration into a wide array of applications, providing solutions that were previously deemed impossible.

As we look towards 2025, we explore the top 10 innovative developments in Zirconia Ceramic that are not only enhancing product performance but also driving sustainability and efficiency. These innovations highlight the material's potential in addressing contemporary challenges and fulfilling the demands of an ever-evolving market. By showcasing these advancements, we aim to illustrate how Zirconia Ceramic is not just a material, but a cornerstone of the future of industry, inspiring new ideas and solutions that will shape our world for years to come.

Zirconia ceramics have emerged as game-changers in aerospace engineering and manufacturing, offering unparalleled strength, heat resistance, and lightweight properties that significantly enhance performance metrics. These advanced materials are paving the way for innovative designs that increase fuel efficiency and reduce emissions while maintaining structural integrity under extreme conditions. Their applications range from turbine components to thermal barriers, showcasing how zirconia ceramics can withstand the rigorous demands of aerospace environments.

**Tips:** When considering zirconia ceramics for your projects, focus on their thermal properties to optimize performance. Conduct thorough material testing to ensure compatibility with existing manufacturing processes, and don't overlook the potential for cost savings through improved durability and performance.

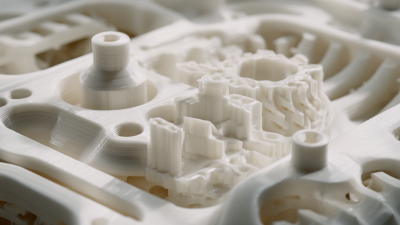

Another notable application is in additive manufacturing, where zirconia ensures high precision and reliability in 3D-printed components. This innovation opens doors to complex geometries that were previously unattainable with traditional materials. By leveraging zirconia's unique properties, manufacturers can achieve lighter yet stronger parts, contributing to the overall advancement of aerospace technologies.

**Tips:** Collaborating with material scientists can enhance the development of tailored zirconia solutions for your specific aerospace needs. Stay updated on the latest advancements in zirconia processing techniques to maximize the benefits of this superior material in your designs.

In 2025, the dental industry is set to undergo a significant transformation, thanks to advancements in zirconia ceramics. These innovative materials are not only enhancing aesthetic outcomes but also improving the functionality and longevity of dental restorations. The high strength and biocompatibility of advanced zirconia ceramics make them ideal for various applications, including crowns, bridges, and implants. These innovations promise to reduce the risk of fractures and wear, addressing long-standing concerns in dental treatments.

Moreover, the introduction of cutting-edge manufacturing techniques, such as additive and subtractive methods, is streamlining the production of zirconia-based dental components. This means that dental practitioners can offer customized solutions with precision-fitting restorations that enhance patient comfort and satisfaction. With the ability to incorporate various shades and translucency levels, these advanced ceramics are revolutionizing the way dental aesthetics are perceived, enabling practitioners to achieve results that closely mimic natural teeth while ensuring durability in challenging oral environments.

In recent years, zirconia ceramics have emerged as a game-changing material across various industries, particularly due to their innovative coatings that significantly enhance durability. According to a report by MarketsandMarkets, the global zirconia ceramics market is projected to reach $3.5 billion by 2025, driven largely by advancements in coating technologies. These next-generation coatings not only provide superior wear resistance but also improve thermal stability, making them ideal for applications in aerospace, automotive, and biomedical fields.

The development of advanced zirconia coatings has allowed manufacturers to create components that withstand extreme conditions while minimizing maintenance and replacement costs. Research from the Journal of Materials Science indicates that innovative coatings can increase the lifespan of zirconia components by up to 50%, offering substantial cost savings and efficiency improvements. With the growing emphasis on sustainability, coatings that enhance the longevity of products align perfectly with modern industries' shift towards more environmentally friendly practices. These innovations firmly position zirconia ceramics at the forefront of materials science, shaping the future of various industrial applications.

| Innovation | Application | Material Properties | Durability Enhancement | Year of Introduction |

|---|---|---|---|---|

| Next-Gen Coatings | Aerospace | High-temperature resistance | 50% increase in lifespan | 2025 |

| Electro-conductive Zirconia | Electronics | Partial conductivity | Improved performance under stress | 2024 |

| Self-healing Ceramics | Medical Devices | Enhanced biocompatibility | Longevity in medical implants | 2025 |

| Ultra-light Zirconia | Automotive | High strength-to-weight ratio | 45% weight reduction | 2025 |

| Thermal Barrier Coatings | Energy Sector | Excellent thermal insulation | 60% reduction in heat loss | 2025 |

Zirconia ceramics are increasingly becoming pivotal in the electronics and semiconductor industries, thanks to their exceptional properties such as high strength, thermal stability, and resistance to wear and corrosion. The Semiconductor Ceramic Packaging Materials Market is projected to reach USD 2.78 billion by 2030, reflecting significant growth driven by the demand for efficient and reliable components in electronic devices. This demand underscores the necessity for advanced materials that can withstand the rigorous conditions typically found in semiconductor manufacturing processes.

Moreover, the advanced technical ceramics market is poised for substantial growth, with an expected size of USD 155.50 billion by 2034, up from USD 88.15 billion in 2024. Within this sector, zirconia and alumina ceramics stand out, together commanding a 44% market share. As industries increasingly prioritize high-performance, lightweight materials, the role of advanced ceramics, including zirconia, is poised to expand significantly, influencing the future of manufacturing in the electronics and semiconductor fields. The integration of these innovations not only enhances product performance but also contributes to the sustainability and efficiency of modern industrial practices.

In 2025, the landscape of zircona ceramic innovations is poised to prioritize sustainability more than ever before. With increasing environmental concerns, manufacturers are focusing on eco-friendly practices that reduce waste and promote circular economies. Notably, advancements in bio-based zirconia production techniques are emerging, using renewable resources that significantly lessen the carbon footprint while maintaining the exceptional mechanical properties required for industrial applications.

Furthermore, the development of recyclable zirconia ceramic products is gaining traction, allowing industries to minimize material waste. These innovations not only enhance the lifecycle of the products but also align with global sustainability goals. Additionally, companies are investing in research to develop energy-efficient production processes, ensuring that the entire lifecycle of zirconia ceramics—from production to disposal—becomes increasingly eco-friendly. As these sustainable practices become more prevalent, they are set to redefine industries, making zirconia ceramics a cornerstone of modern, environmentally responsible manufacturing.

This chart represents the anticipated impact scores of various innovative developments in zirconia ceramics for 2025 across different dimensions like energy efficiency, waste reduction, and durability, showcasing a strong focus on sustainability and eco-friendliness.