Leave Your Message

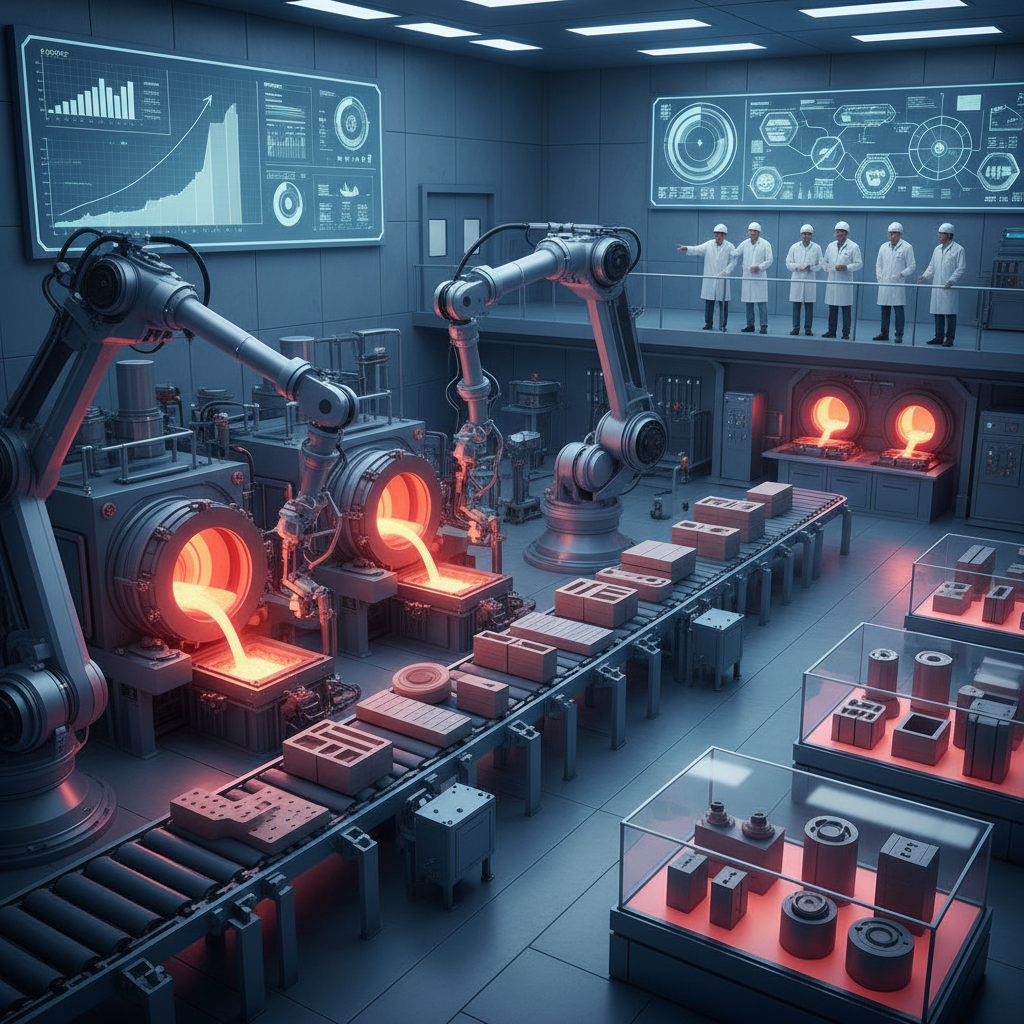

The demand for high-performance materials in the ceramics industry has been on the rise, driven primarily by advances in manufacturing processes and the need for enhanced product durability. Among these materials, Corundum Mullite Sagger has emerged as a leading choice due to its superior thermal stability and mechanical strength. Industry reports indicate that the global market for ceramic saggers, particularly those made from Corundum Mullite, is projected to grow at a CAGR of over 5% from 2023 to 2028, fueled by expanding applications in the refractory sector and increasing automation in production facilities.

As we approach 2025, it is essential for industry stakeholders to stay informed about the top Corundum Mullite Sagger products that stand out for their innovative properties and value. The selection of high-quality saggers can significantly influence the efficiency and outcome of ceramic firing processes, underscoring the importance of understanding product specifications and performance data. This article will highlight the top five Corundum Mullite Sagger products available in the market, providing a comprehensive overview of their benefits, applications, and how they can enhance production efficiency within the ceramics industry.

Corundum mullite saggers are essential components in the ceramic industry, aiding in the effective firing of high-value materials. Known for their exceptional thermal stability and low thermal conductivity, these products withstand extreme firing temperatures, making them ideal for applications in porcelain and advanced ceramics. According to a recent market report by Research and Markets, the demand for corundum mullite saggers is projected to grow at a CAGR of 5.2% from 2023 to 2028, reflecting their increasing importance in high-performance ceramics.

One of the key advantages of corundum mullite saggers is their structural integrity, which reduces the risk of deformation during the firing process. Their high resistance to chemical corrosion and thermal shock also ensure longer service life, resulting in lower operational costs. A study from the International Journal of Applied Ceramics Technology indicates that companies utilizing advanced saggers can increase their production efficiency by up to 20%, thereby maximizing output without compromising on quality. These features make corundum mullite saggers not only necessary but a competitive advantage for manufacturers looking to enhance their production capabilities.

The corundum mullite market is experiencing significant growth in 2025, driven by advancements in technology and increasing demand across various industries. Leading brands are positioning themselves at the forefront of this sector, leveraging innovative manufacturing techniques and enhanced material performance. Companies such as HarbisonWalker International and Vesuvius are recognized for their superior product lines that cater to diverse applications, including metallurgical, refractory, and ceramics industries.

In addition, brands like Morgan Advanced Materials and Saint-Gobain are making strides with their specialized corundum mullite saggers, known for their durability and high-temperature resistance. These products meet the evolving needs of modern manufacturing processes, providing solutions that offer both efficiency and sustainability. As competition intensifies, these top brands are not only focusing on product excellence but also on customer service and support, ensuring that they remain leaders in the corundum mullite market for years to come.

Corundum mullite saggers have become increasingly pivotal in modern industrial applications, particularly in sectors such as ceramics, metal processing, and glass manufacturing. According to a report by Market Research Future, the global ceramics market, which heavily utilizes these saggers, is expected to reach a valuation of approximately $1.1 trillion by 2025. This growth can be attributed to the superior thermal stability and low thermal expansion properties of corundum mullite, making these saggers ideal for high-temperature applications.

Additionally, the innovative application of corundum mullite saggers in additive manufacturing is gaining traction. A study published in the Journal of Materials Science indicates that the unique composition of corundum mullite allows for enhanced mechanical strength and durability, essential for supporting intricate designs during the sintering process. As industries seek to optimize production efficiency and product quality, the demand for high-performance materials like corundum mullite saggers is anticipated to rise, reinforcing their status in cutting-edge manufacturing technologies.

In 2025, the market for corundum mullite saggers is poised to present several innovative products that stand out for their performance and durability. This comparative analysis examines the top contenders, focusing on their unique features, applications, and overall effectiveness in high-temperature environments. The leading products are designed to optimize thermal stability and mechanical strength, making them ideal for industries such as ceramics and glass manufacturing.

When evaluating the best corundum mullite saggers, it is essential to consider factors such as thermal shock resistance, longevity, and cost-effectiveness. The top products incorporate advanced material technology that enhances their durability and performance under extreme conditions. Additionally, customer feedback plays a crucial role in identifying which saggers not only meet but exceed expectations in real-world applications. This analysis helps industry professionals make informed choices that align with their operational needs and efficiency goals.

| Product Name | Material Composition | Max Temperature (°C) | Thermal Conductivity (W/m·K) | Kiln Type Compatibility |

|---|---|---|---|---|

| Product A | Corundum & Mullite | 1400 | 5.0 | Electric, Gas |

| Product B | High Purity Mullite | 1450 | 4.5 | Tunnel, Shuttle |

| Product C | Corundum-Based | 1500 | 6.0 | Gas, Electric |

| Product D | Silica & Alumina | 1350 | 4.0 | Batch, Down-Draft |

| Product E | Alumina Rich | 1550 | 7.5 | High Temperature |

The advancement in corundum mullite sagger technology is set to reshape the landscape of industrial applications. As industries evolve, the demand for high-performance materials has spurred innovative designs that enhance thermal stability and mechanical strength. Future trends indicate a shift towards more sustainable and eco-friendly production techniques, which not only minimize environmental impact but also reduce manufacturing costs.

The integration of advanced materials, such as nanotechnology, is expected to improve the durability and efficiency of saggers, making them ideal for extreme conditions in various kilns.

Moreover, the customization of corundum mullite saggers is becoming increasingly prominent. Manufacturers are focusing on creating tailored solutions that meet specific client needs, whether in terms of size, shape, or thermal properties. This trend towards personalization, along with the implementation of 3D printing technologies, will allow for more intricate designs and faster production times. As the market grows, the emphasis on research and development in materials science will undoubtedly lead to breakthroughs that enhance performance and longevity, positioning corundum mullite saggers at the forefront of ceramic technology in the coming years.