Leave Your Message

In the realm of high-temperature applications, the materials utilized play a pivotal role in enhancing efficiency and performance. Among these materials, the Cordierite Mullite Sagger has emerged as a critical component in various industries, particularly in ceramics and glass production. Recent industry reports indicate that the global market for high-temperature materials is expected to grow significantly, with projections suggesting a compound annual growth rate (CAGR) of approximately 5.8% from 2023 to 2028. This surge is driven largely by the increasing demand for durable and heat-resistant products that can withstand extreme conditions.

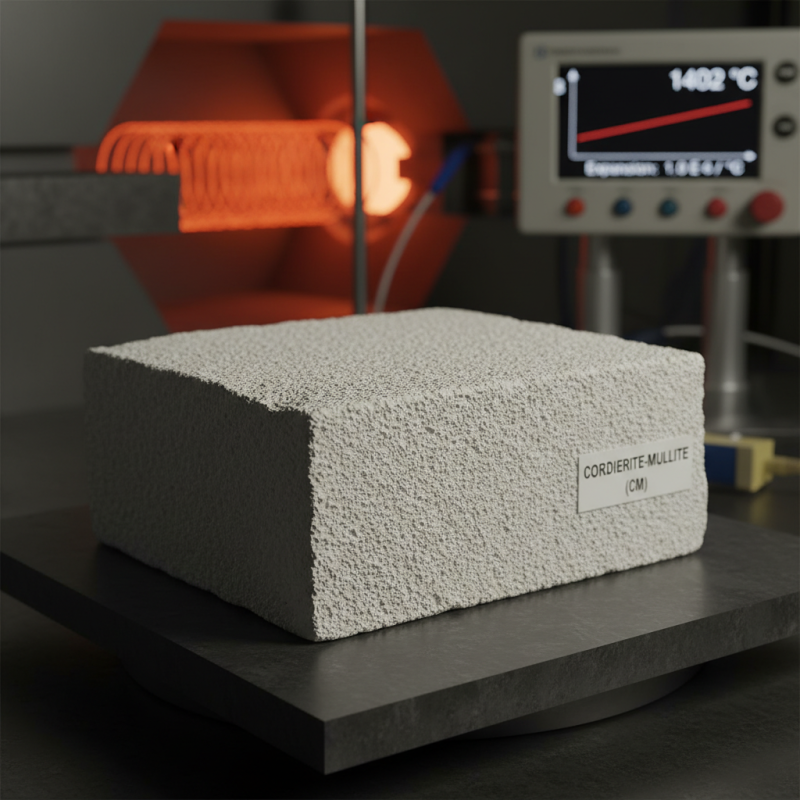

The Cordierite Mullite Sagger is particularly notable for its exceptional thermal stability and low thermal expansion properties, which are essential attributes in ensuring the integrity of fired components during high-temperature processing. Studies have shown that using Cordierite Mullite Saggers can enhance the efficiency of firing cycles, minimize energy consumption, and reduce the risk of product defects. As industries continue to seek ways to optimize production processes while maintaining high quality, the advantages of utilizing Cordierite Mullite Saggers cannot be overstated. Understanding these benefits is vital for industries aiming to remain competitive in a rapidly evolving market.

Cordierite mullite saggers are increasingly recognized for their critical role in high-temperature applications, particularly in industries such as ceramics, glass, and metal processing. One of the key advantages of using cordierite mullite saggers is their exceptional thermal shock resistance. This property allows them to withstand rapid temperature changes without cracking, making them ideal for processes that involve extreme heat fluctuations. As a result, manufacturers can achieve greater efficiency and reduced downtime during production.

In addition to thermal stability, cordierite mullite saggers exhibit excellent mechanical strength at elevated temperatures. This characteristic ensures that they can support heavy loads without deformation, which is crucial for maintaining the integrity of the materials being processed. Furthermore, their low thermal conductivity contributes to energy efficiency by minimizing heat loss, which is a significant consideration in high-temperature environments. This combination of durability and efficiency makes cordierite mullite saggers an excellent choice for modern industrial applications, where performance and cost-effectiveness are paramount.

| Benefit | Description | Application Areas |

|---|---|---|

| High Thermal Shock Resistance | Cordierite mullite sagger can withstand rapid temperature changes without cracking. | Ceramic Manufacturing, Glass Production |

| Low Thermal Expansion | Minimizes the risk of deformation during heating and cooling cycles. | High-Temperature Firing |

| Excellent Mechanical Strength | Provides durability and support under heavy loads in high-temp environments. | Kilns, Furnaces |

| Chemical Stability | Resistant to various chemical reactions that may occur at high temperatures. | Metallurgy, Glass and Ceramic Processing |

| Cost-Effectiveness | Longer lifespan leads to reduced replacement costs. | Manufacturing Processes |

Cordierite mullite, a distinct ceramic material, has gained recognition for its exceptional thermal properties, making it an ideal choice for high-temperature applications. One of the key properties that set cordierite mullite apart is its low thermal expansion coefficient, which is critical for components subjected to rapid temperature changes. Research indicates that cordierite mullite maintains dimensional stability up to 1400°C, with expansion rates often reported as low as 1.0 x 10⁻⁶/°C. This stability minimizes the risk of thermal shock, a crucial factor in industries such as ceramics, glass, and metallurgy where temperature fluctuations are common.

Additionally, cordierite mullite boasts outstanding thermal shock resistance, attributed to its unique crystalline structure. This structure allows for effective heat dissipation and reduces the likelihood of crack formation under thermal stress. According to industry reports, materials with these properties can withstand up to 60% greater temperature shifts compared to traditional refractory materials. Moreover, the excellent mechanical strength of cordierite mullite at elevated temperatures ensures durability and longevity in high-heat environments, enhancing operational efficiency and reducing maintenance costs for manufacturing processes that require prolonged exposure to extreme temperatures.

Cordierite mullite saggers are increasingly recognized for their crucial role in high-temperature industrial applications, primarily due to their excellent thermal stability and resistance to thermal shock. These properties make them ideal for processes such as ceramics firing, glass manufacturing, and metal casting, where maintaining an optimal environment during production is essential. The ability of cordierite mullite to endure extreme temperatures without deforming ensures that the structural integrity of the products being processed is maintained.

When considering the use of cordierite mullite saggers, it is essential to ensure proper handling to maximize their lifespan. Tips for effective use include preheating the saggers gradually to avoid thermal shock and maintaining consistent temperature profiles during firing processes to prevent any unforeseen damage. Furthermore, the saggers should be kept clean and free from contaminants, as residues can impact the quality of the final products significantly.

In addition to their thermal properties, cordierite mullite saggers also provide excellent dimensional stability, which is vital in applications where precision is key. This stability helps in reducing production defects, thereby optimizing operational efficiency. Implementing a routine inspection and maintenance schedule can be beneficial for ensuring that the saggers remain in top condition, contributing to a smoother production flow and superior product quality. Understanding these aspects can lead to improved outcomes in various industrial processes reliant on high-temperature applications.

Cordierite mullite saggers are increasingly recognized for their advantages in high-temperature applications, particularly in the ceramics and glass industries. When compared with other materials, such as alumina and zirconia, cordierite mullite demonstrates superior thermal stability and lower thermal expansion coefficients. According to a study published in the "Journal of Materials Science," cordierite mullite exhibits an impressive thermal shock resistance up to 1200°C, enabling it to withstand rapid temperature changes without significant structural damage. This property makes it particularly valuable for kilns used in the firing of ceramic products.

Furthermore, cordierite mullite's lightweight nature provides significant benefits in reducing operational costs. Reports from the American Ceramic Society indicate that using lighter saggers can lead to energy savings of approximately 15-20% in high-temperature processes, optimizing thermal efficiency and minimizing wear and tear on furnace components. In contrast, traditional materials such as alumina can contribute to higher system weight and energy expenses. This comparative advantage highlights why cordierite mullite is becoming a preferred choice for manufacturers looking to enhance production efficiency while maintaining high-quality standards in high-temperature applications.

As industries progress toward more demanding high-temperature applications, the development of cordierite mullite saggers is gaining significant attention. In 2025, the focus will not only be on enhancing material properties but also on sustainability and energy efficiency. Research indicates that cordierite mullite exhibits superior thermal shock resistance and lower thermal expansion, making it ideal for environments that require enduring high temperatures. According to a recent industry report, the market for cordierite mullite products is expected to grow by approximately 8.5% annually over the next five years, driven by increasing demand in sectors like ceramics and metal processing.

Future trends in cordierite mullite sagger development are anticipated to leverage advanced manufacturing technologies, such as additive manufacturing and nano-materials, to enhance performance and durability. This evolution is supported by data indicating that saggers produced using these innovative techniques can reduce production cycle times by 30%, significantly improving operational efficiency. Additionally, enhancing the recyclability of sagger materials is expected to be a key focus area. Industries are increasingly motivated to adopt sustainable practices, and this approach aligns with global efforts to minimize waste and reduce carbon footprints.

Tips: When selecting cordierite mullite saggers for your applications, consider not just the thermal properties but also the long-term reliability and sustainability of the product. Conduct a thorough analysis of potential suppliers and their manufacturing processes to ensure that their offerings align with your operational goals. Embracing innovation could not only improve your process efficiencies but also contribute to a more sustainable production model.

This chart illustrates the projected benefits of Cordierite Mullite Sagger in high-temperature applications by 2025. The data reflects improvements in thermal shock resistance, mechanical strength, reduced thermal conductivity, and overall longevity compared to traditional materials.