Leave Your Message

Zirconia Ceramic is a remarkable material known for its strength and durability. This advanced ceramic is widely used in various industries. From dental applications to aerospace components, it plays a crucial role. Its unique properties allow for both aesthetic appeal and resilience.

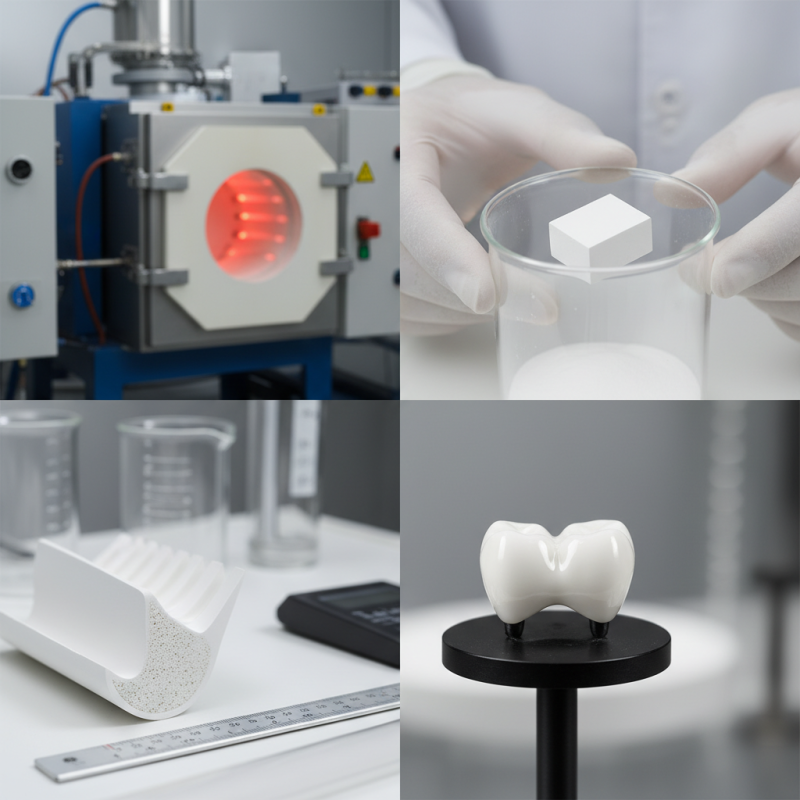

The manufacturing of Zirconia Ceramic involves complex processes. This includes high-temperature sintering and careful selection of raw materials. Such practices ensure that the final product meets high standards. However, challenges remain in achieving uniform quality. Variations can lead to performance discrepancies, which need addressing.

In the dental field, Zirconia Ceramic has transformed restorative practices. Dentists appreciate its natural appearance. Yet, not all Zirconia materials are created equal. Some may exhibit flaws or inconsistencies. Continuous research is needed to optimize its applications and benefits.

Zirconia ceramic is a remarkable material widely used in various industries. It is made from zirconium dioxide, which gives it exceptional strength and toughness. This ceramic is known for its high resistance to wear and corrosion, making it suitable for use in dental applications and cutting tools.

In dental applications, zirconia ceramic allows for the creation of durable and attractive dental prosthetics. Its natural appearance closely resembles that of tooth enamel. However, despite these benefits, zirconia can be challenging to work with. The material requires precise machining and handling during the production process to avoid defects. Even minor flaws can compromise its integrity.

Additionally, while zirconia is very strong, it can be brittle under certain conditions. Some users report difficulty in achieving a perfect fit when using zirconia implants. This highlights the importance of skilled craftsmanship in the manufacturing process. Overall, zirconia ceramic holds great potential, but achieving its full benefits requires careful consideration and expertise.

| Property | Description | Importance |

|---|---|---|

| Material Composition | Zirconium dioxide (ZrO2) | Base material for high-performance ceramics. |

| Strength | High flexural strength and toughness | Ideal for dental implants and prosthetics. |

| Biocompatibility | Highly biocompatible | Safe for medical applications in the human body. |

| Thermal Stability | Excellent thermal resistance | Used in high-temperature applications. |

| Optical Properties | Good translucency | Aesthetic applications in dentistry. |

Zirconia ceramic has become a crucial material in various industries. Its key properties make it highly sought after. The unique combination of durability, biocompatibility, and resistance to wear makes zirconia an excellent choice for applications like dental implants and medical devices. Reports from the Journal of Materials Science indicate that zirconia is five times tougher than conventional ceramics.

One key property of zirconia is its high fracture toughness. This means it can withstand significant stress without cracking. According to a study published in the Materials Research Bulletin, zirconia can handle pressures up to 1,200 MPa. This toughness is essential for applications where structural integrity is vital. However, challenges remain in its brittleness, particularly under specific conditions. This characteristic warrants further investigation and development.

Another important aspect is its thermal stability. Zirconia retains strength even at elevated temperatures. This property makes it suitable for environments where other materials fail. However, it can also present issues in manufacturing processes, leading to inconsistencies in the final product. Thus, while zirconia shows great promise, its production and application come with challenges that require careful consideration.

Zirconia ceramic is a versatile material with significant applications across various industries. Its exceptional strength and wear resistance make it a favored choice in fields such as dental and biomedical engineering. According to a report from the Journal of Biomedical Materials Research, zirconia has a fracture toughness significantly higher than alumina, making it ideal for dental prosthetics.

In the automotive sector, zirconia is increasingly used in fuel cells and sensors. A study by the International Journal of Hydrogen Energy highlighted that zirconia components can withstand high temperatures and corrosive environments. These qualities ensure reliable performance in challenging conditions, which is crucial for vehicle efficiency. However, the cost of high-purity zirconia can be a barrier for widespread adoption.

The electronics industry also benefits from zirconia's properties. It serves as an insulator in various components, contributing to the miniaturization of electronics. While it enhances device performance, the processing techniques can be complex and costly. As industries continue to innovate, refining these methods could lead to broader accessibility and more sustainable practices.

Zirconia ceramic has gained attention for its unique properties. Its strength and resilience are unmatched. This material is highly resistant to wear and is often used in demanding environments. This makes it ideal for dental applications and industrial components.

One of the key advantages of zirconia ceramic is its biocompatibility. It can be safely used in medical implants. This opens up new possibilities in healthcare. The smooth surface enhances comfort and aids in healing. However, achieving the perfect formulation can be challenging, leading to inconsistencies in quality.

Another notable benefit is its aesthetic appeal. Zirconia can mimic the appearance of natural tooth enamel. This gives patients a reason to smile confidently. Yet, the production process requires precision. Any slight error can affect the final product. It's a constant reminder of the importance of attention to detail in ceramic manufacturing.

Zirconia ceramic has become increasingly significant in various fields. Its versatility extends to

dental applications, electronics, and even aerospace. With its

high strength and excellent stability, zirconia is a

preferred choice for creating durable products. As industries evolve, so do the techniques for

zirconia usage. Innovations in manufacturing processes are emerging, improving the overall

performance of this material.

Future trends indicate a shift toward more sustainable practices in zirconia production.

Researchers are exploring ways to reduce energy consumption and increase recyclability. This

could lead to eco-friendly options

that satisfy modern consumer demands. Emerging technologies

like 3D printing also promise to revolutionize zirconia applications. Customization might become

standard, with tailored solutions for specific needs.

Tip: When considering zirconia for your projects, always test samples first.

Factors like strength and compressibility can vary. Another important aspect is to stay updated

on advancements in zirconia technology. This ensures that you are utilizing the best available options

in your applications. Remember, not all zirconia products are created equal.